Chain

一种链条、导件的技术,应用在链条领域,能够解决摩擦损耗大、滑动阻力大、汽车发动机动力损失多等问题,达到简单结构、降低摩擦阻力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

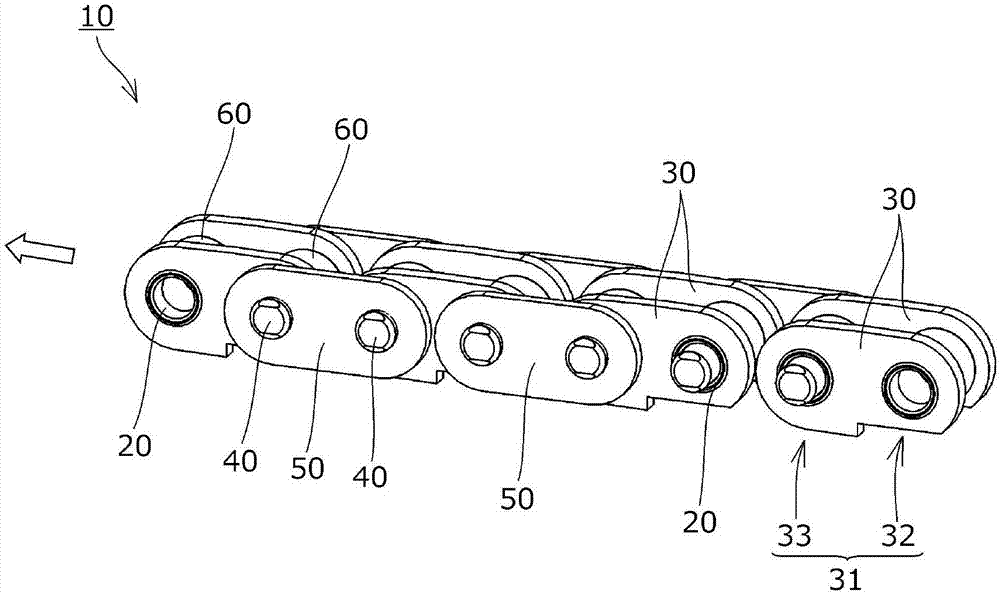

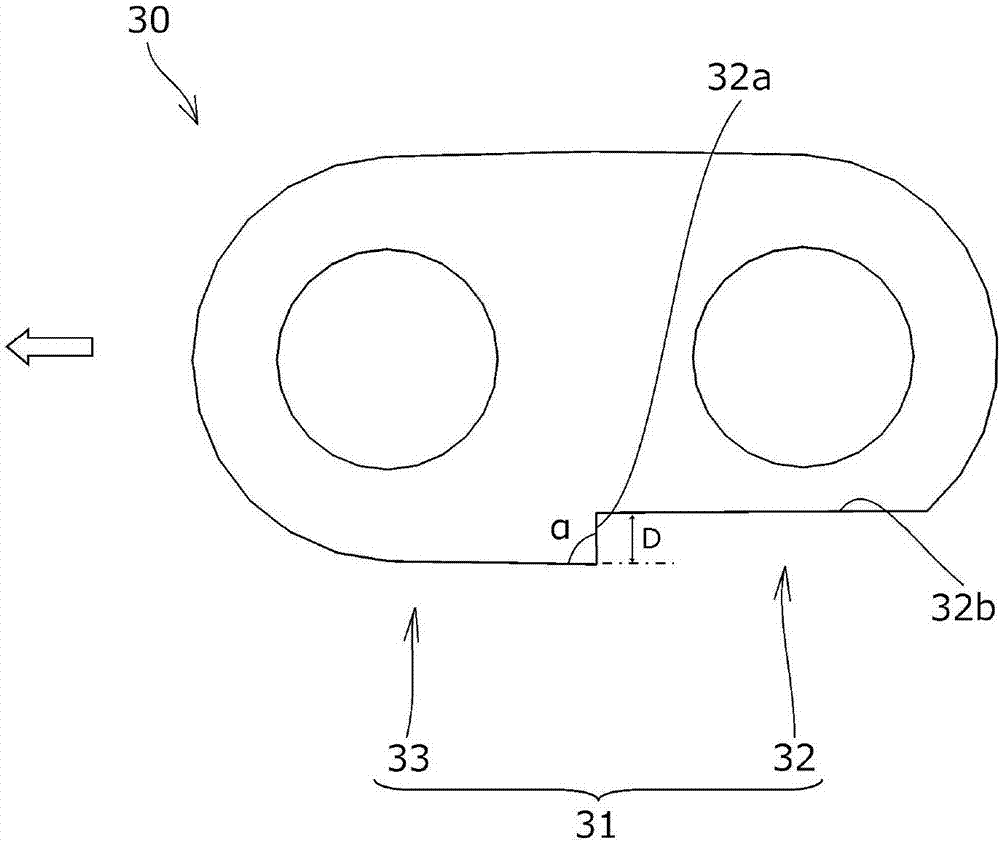

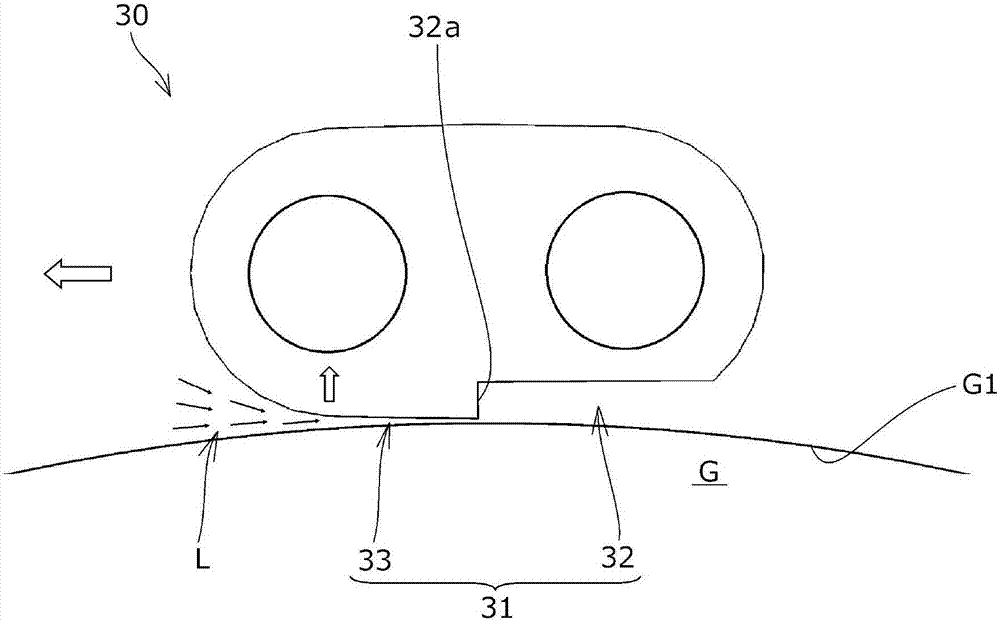

[0025] Hereinafter, the chain 10 which concerns on one Embodiment of this invention is demonstrated based on drawing.

[0026] The chain 10 of the present embodiment is configured as a timing chain for an automobile engine, such as figure 1 As shown, it is equipped with: a plurality of internal connectors formed by fixing the two ends of the front and rear pair of bushings 20 to the bushing holes of the left and right pair of inner plates 30; A plurality of external connecting parts formed by the pin holes of the external flat plate 50; and the roller 60 embedded by the bushing 20. By inserting the connecting pin 40 into the bush 20, the inner link and the outer link are alternately linked in the chain length direction so as to be bendable.

[0027] In this embodiment, the inner plate 30 is set to have a greater thickness in the height direction of the plate than the outer plate 50, and is configured so that only the inner plate 30 slides relative to the chain guide G, in ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com