Rolling sleeve for textile guide roller

A technology of rolling sleeves and guide rollers, which is applied in the direction of progressive dryers, drying solid materials, dryers, etc., can solve the problem that water vapor cannot be emitted, and achieve the effect of good emission and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

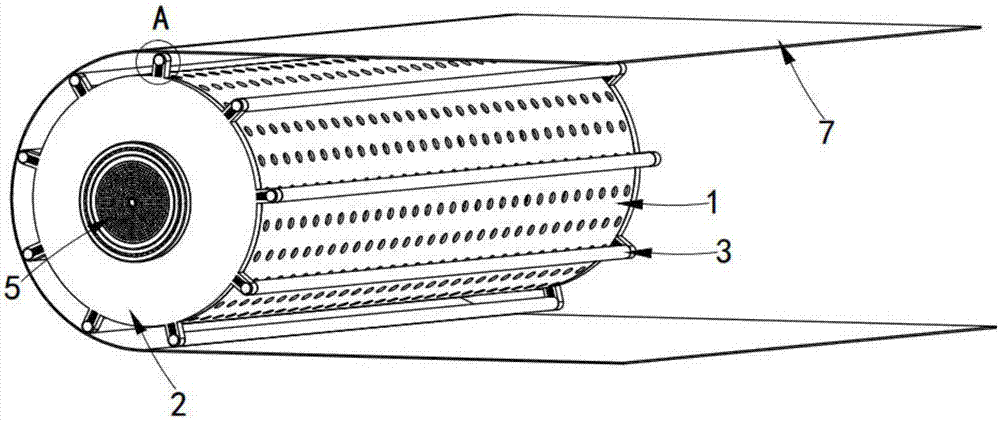

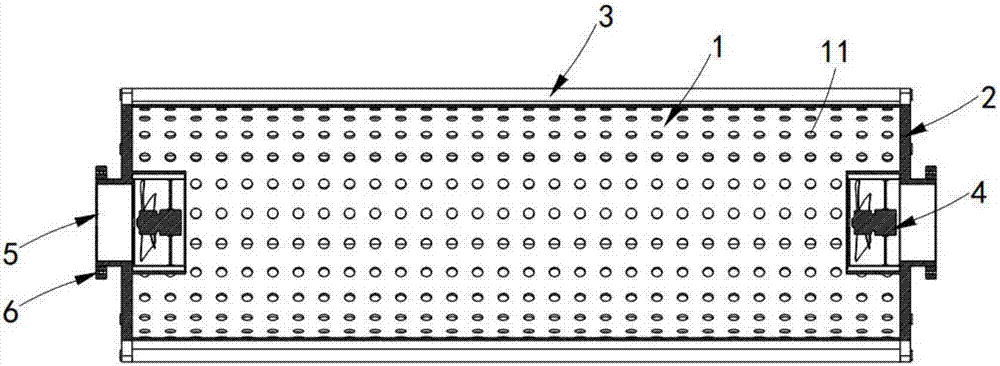

[0033] Such as figure 1 and figure 2 As shown, a rolling sleeve for a textile guide roller, comprising:

[0034] A sleeve 1, the sleeve 1 is arranged in a circle, its interior is hollow, and its two ends are opened;

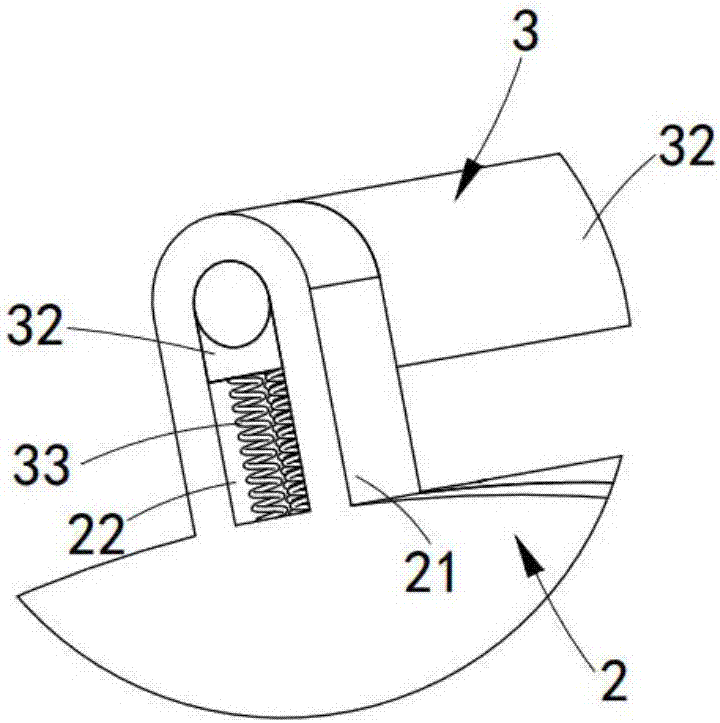

[0035] An end cap 2, the end cap 2 is arranged in a circular shape, which is symmetrically arranged on both ends of the sleeve 1, and is fixedly connected to the sleeve 1;

[0036] A plurality of elastic components 3 are arranged on the outside of the sleeve 1 , arranged along the axial equidistant circumference of the sleeve 1 , and both ends of which are arranged on the end cap 2 .

[0037] It should be noted that, when the sleeve 1 rotates, the elastic component 3 rotates with the sleeve 1 , and the textile 7 wraps around the outside of the elastic component 3 , and is transported with the rotation of the elastic component 3 .

[0038] It is further explained that there is a gap between the elastic component 3 and the sleeve 1 , and during the conveyance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com