Reflection-free wave flume wave maker

A wave generator and secondary reflected wave technology, applied in instruments, program control in sequence/logic controllers, control/regulation systems, etc., to improve the efficiency of absorbing waves, reduce data transmission delay, and improve absorption efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

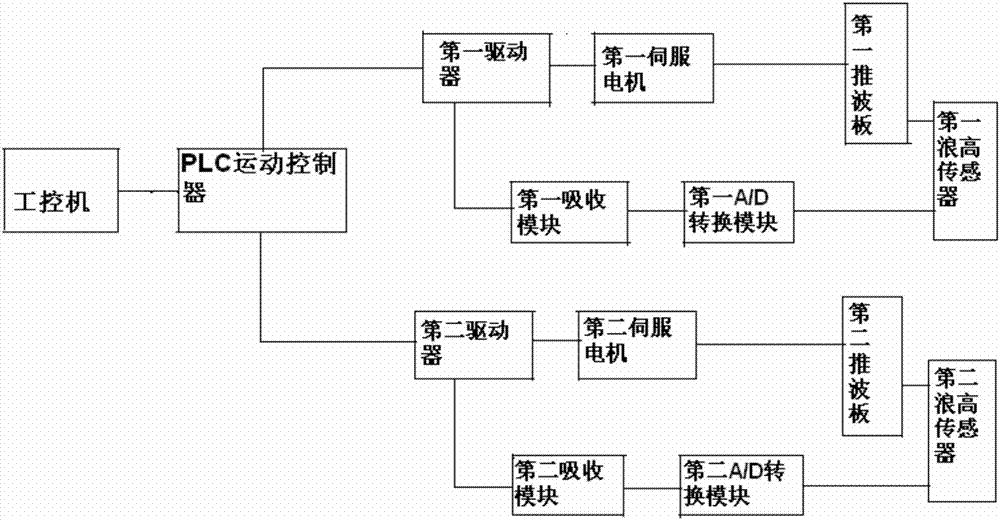

[0027] Such as figure 1 As shown, a non-reflection wave tank wave maker consists of an industrial computer, a PLC motion controller, and the first and second drivers to form a control module responsible for the state control of the entire wave maker system. The industrial computer includes two parts, the host and the LCD display. The host hardware description: Intel Core i3 dual-core four-thread processor, main frequency 3.3GHz, memory 4GB, running embedded Windows7 system, dual 100Mbps network interface. The industrial computer is used to run the upper computer program of the wave maker, including the functions of generating the motion control sequence corresponding to the target waveform, controlling the PLC program, detecting the running state of the motor, performing wave height spectrum analysis, and real-time display. The network communication between the industrial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com