Rotary type banana crown cutting device

A rotary and falling combing technology, which is applied in application, food processing, food science, etc., can solve the problems of low level of mechanization application, abrasion of banana skin, and low operating efficiency, so as to reduce physical labor intensity, stabilize quality, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

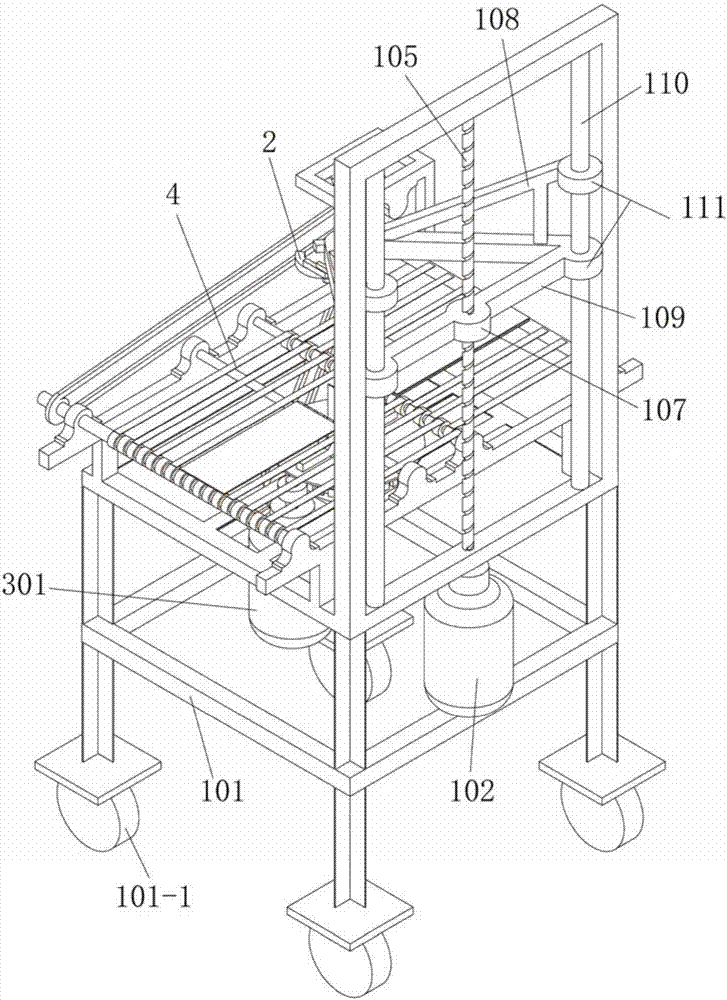

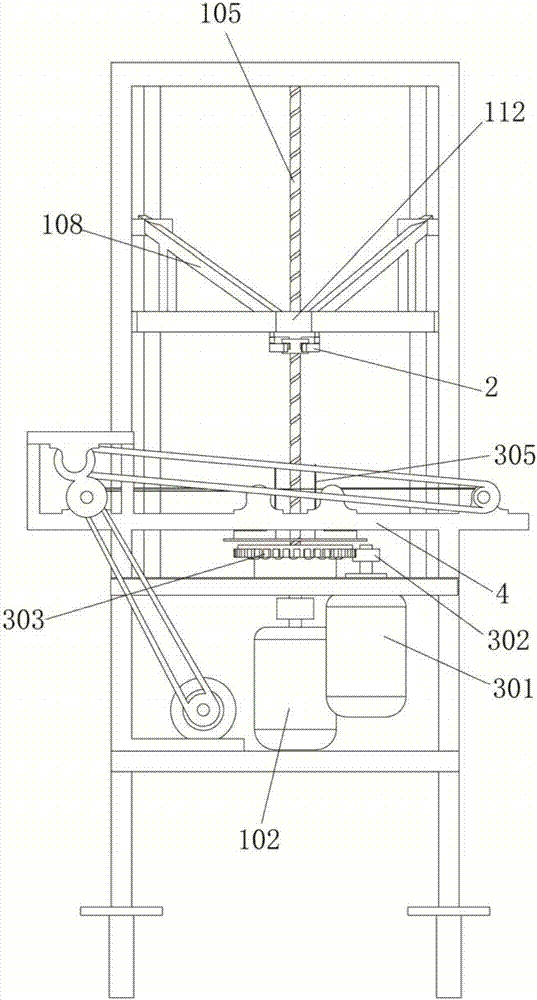

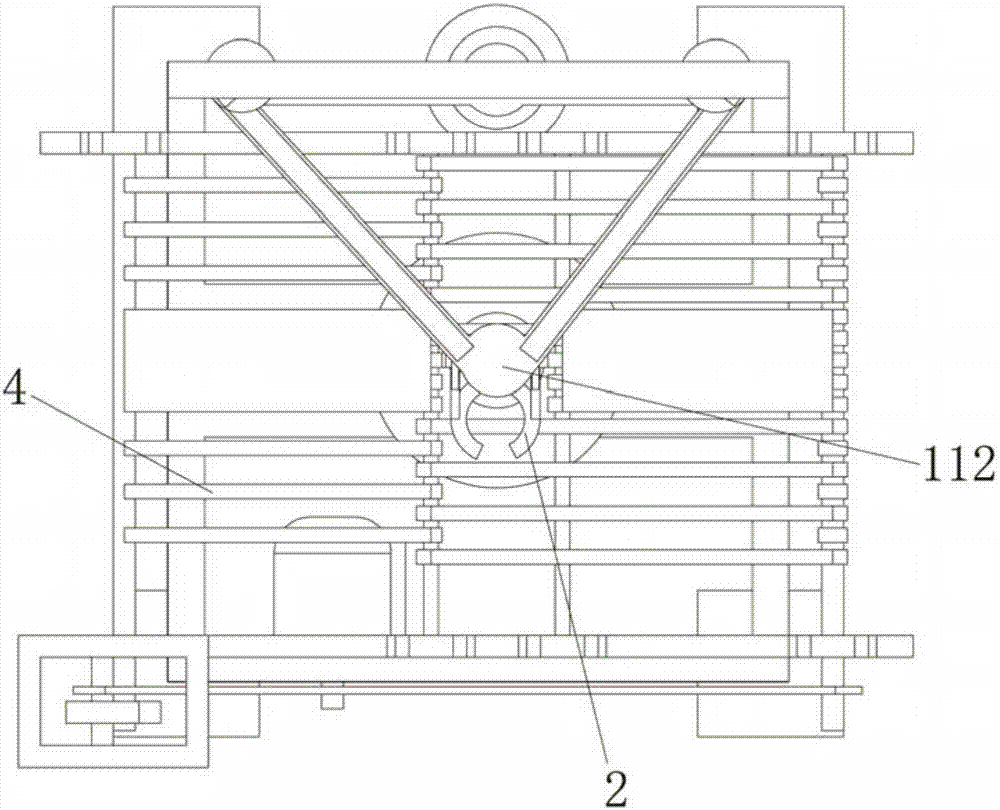

[0032] see Figure 1 to Figure 10 As shown, the rotary combing device for bananas described in this embodiment includes a banana ear lifting mechanism, a fruit shaft clamping mechanism 2, a rotary combing cutter, and a banana comb transport mechanism 4. The banana ear lifting mechanism includes a belt A frame 101 with casters 101-1, a first motor 102, a shaft coupling 103, a bearing with seat 104, a screw mandrel 105, a screw mandrel nut 106, a nut seat 107, a triangular bracket 108, a connecting plate 109, an optical axis 110, Linear slider 111, fixed block 112, the first motor 102 is installed on the frame 101, the first motor 102 is connected with the screw mandrel 105 through the shaft coupling 103, drives the screw mandrel 105 to do rotary motion, that is, the screw mandrel drive , the two ends of the screw rod 105 are vertically installed on the frame 101 through the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com