A kind of toothpaste for the development of dental plaque and preparation method thereof

A technology for dental plaque and toothpaste, applied in the field of oral care, can solve the problems of easy pollution, poor dispersion and stability, and achieve the effects of preventing pollution, good dispersion and stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

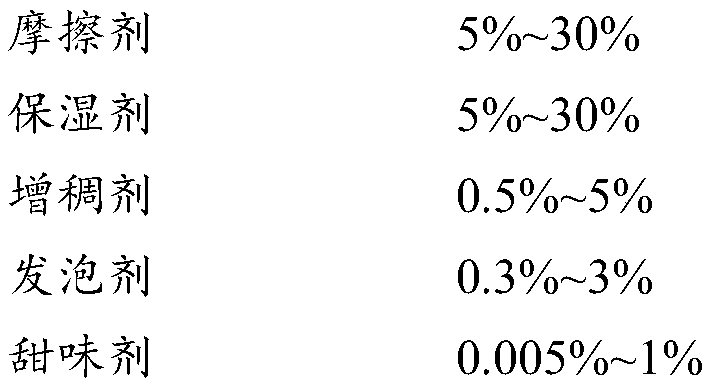

Method used

Image

Examples

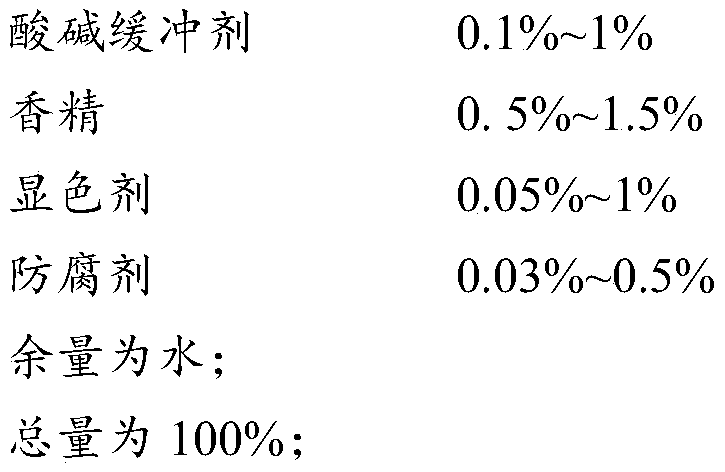

Embodiment 1

[0041]

[0042]

[0043] The preparation method of this toothpaste is as follows:

[0044] (1) Disperse CMC and xanthan gum in PEG-400 and glycerin, stir and disperse evenly to ensure no agglomeration.

[0045] (2) Dissolve sodium saccharin, crystalline sodium pyrophosphate, and sodium benzoate in water, then add sorbitol, acid red 92 and food blue 2, and stir for 15 minutes to fully mix.

[0046] (3) Mix the materials of (1) and (2) above, add silicon dioxide, and stir at 3000r / min for 15min under vacuum.

[0047] (4) Add essence and sodium lauryl sulfate, and stir for 20 minutes at a speed of 2000 r / min under vacuum. After passing the test, it is filled and packaged to make a finished toothpaste.

Embodiment 2

[0049]

[0050] (1) Disperse CMC and xanthan gum in PEG-400 and glycerin, stir and disperse evenly to ensure no agglomeration.

[0051] (2) Dissolve sodium saccharin, crystalline sodium pyrophosphate, and sodium benzoate in water, then add sorbitol, acid red 92 and food blue 2, and stir for 15 minutes to fully mix.

[0052] (3) Mix the materials of (1) and (2) above, add silicon dioxide, and stir at 3000 r / min for 18 min under vacuum.

[0053] (4) Add essence and sodium lauryl sulfate, and stir for 17 minutes at a speed of 2000 r / min under vacuum.

[0054] (5) After passing the test, fill and pack to make toothpaste finished product.

Embodiment 3

[0056]

[0057] (1) Disperse CMC and xanthan gum in PEG-400 and glycerin, stir and disperse evenly to ensure no agglomeration.

[0058] (2) Dissolve sodium saccharin, crystalline sodium pyrophosphate, and sodium benzoate in water, then add sorbitol, acid red 92 and food blue 2, and stir for 15 minutes to fully mix.

[0059] (3) Mix the materials of (1) and (2) above, add silicon dioxide, and stir at 3000 r / min for 20 min under vacuum.

[0060] (4) Add essence and sodium lauryl sulfate, and stir for 15 minutes at a speed of 2000 r / min under vacuum.

[0061] (5) After passing the test, fill and pack to make toothpaste finished product. Run performance tests.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com