Multi-span greenhouse surface cleaning machine

A technology for a greenhouse and a cleaning machine, which is applied in the fields of greenhouse cultivation, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of low cleaning efficiency, poor stability, time-consuming and labor-intensive, etc., and achieves high cleaning speed and high mechanical properties. , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

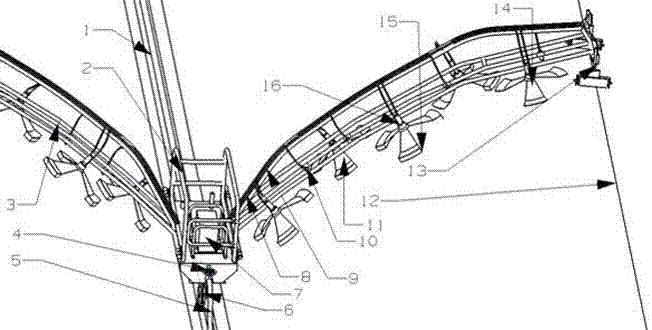

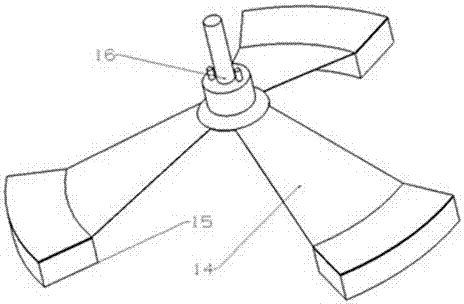

[0029] Embodiment 1: as Figure 1 to Figure 3 As shown, a multi-span greenhouse roof cleaning machine is made up of a car body, a prime mover, a brush and a walking rail wheel. The lower end of the car body is longitudinally provided with two traveling rail wheels, which are driven by the prime mover on the car body. The traveling rail wheels are located on the gutter track between the multi-span greenhouses, and the longitudinal direction of the car body coincides with the longitudinal direction of the gutter track. , The rear of the car body is equipped with a high-pressure water pipe with a switch. There are symmetrical cleaning devices on both sides of the upper end of the car body. Since the two cleaning devices are symmetrically located on both sides of the upper end of the car body, only the cleaning device on one side will be described.

[0030] The cleaning device is used to automatically clean the multi-span greenhouse surfaces on both sides of the gutter track at ...

Embodiment 2

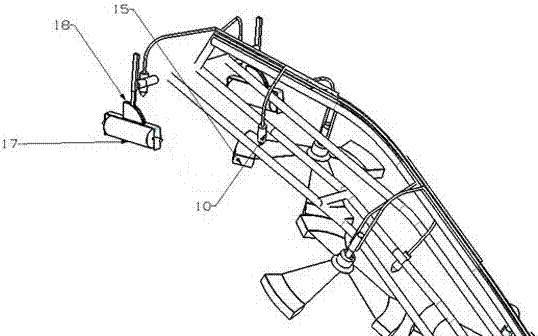

[0035] Embodiment 2: as Figure 4 to Figure 6 As shown, a multi-span greenhouse roof cleaning machine is made up of a car body, a prime mover, a brush and a walking rail wheel. The lower end of the car body is longitudinally provided with two traveling rail wheels, and the traveling rail wheels are driven by the drive motor 26 positioned on the car body on one side of the traveling rail wheels. The walking rail wheels are positioned on the gutter track between the multi-span greenhouses, the longitudinal direction of the car body coincides with the longitudinal direction of the gutter track, and the rear of the car body is provided with a high-pressure water pipe 5 with a switch. There are symmetrical cleaning devices on both sides of the upper end of the car body. Since the two cleaning devices are symmetrically located on both sides of the upper end of the car body, only the cleaning device on one side will be described.

[0036] Described cleaning device is: a hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com