Gas insulation protection jacking electrolytic machining cathode system and machining method

A gas-insulated, cathode technology, applied in the direction of processing electrodes, electric processing equipment, electrochemical processing equipment, etc., can solve problems such as stray corrosion, reduce impact and improve processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention are described in detail below.

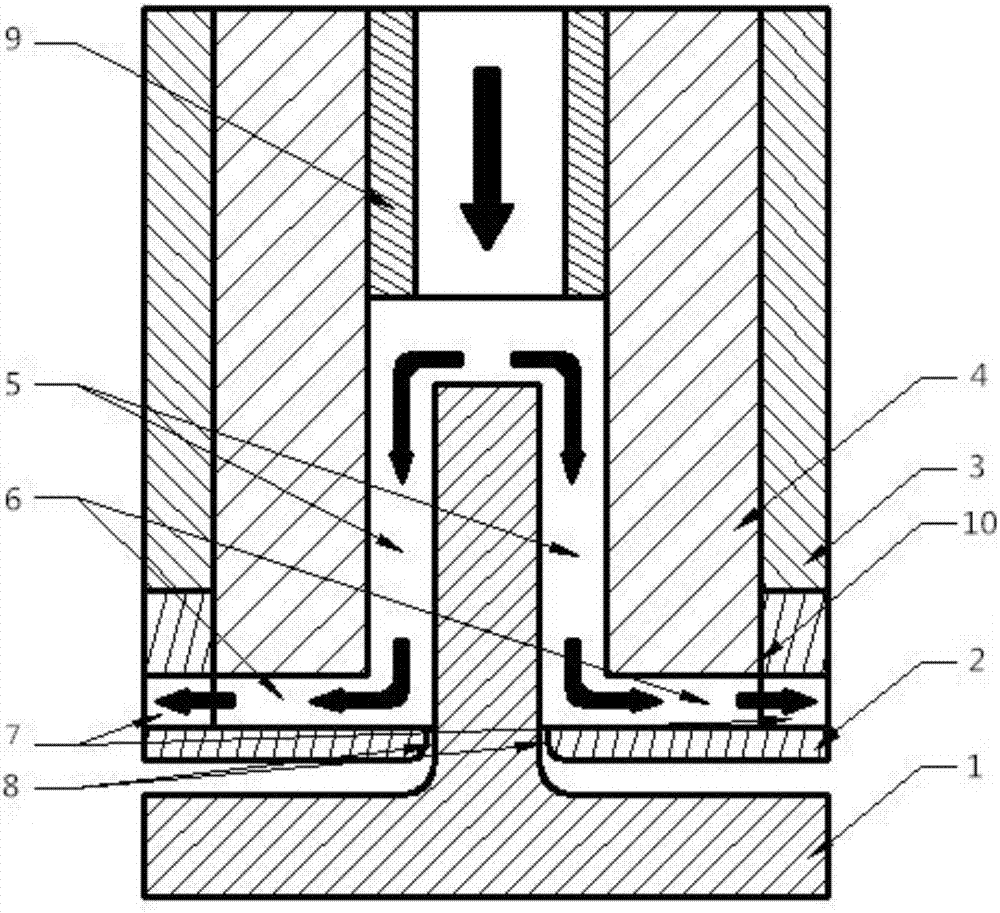

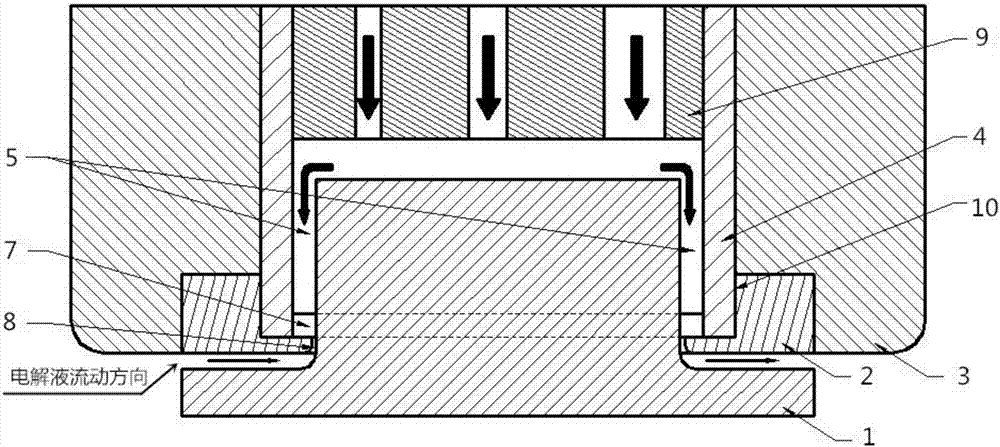

[0016] Implementation of the present invention-"a cathode system and processing method for electrolytic processing of gas-insulated protective casing", the device mainly includes a casing cathode body, a cathode head, a ventilation module, a gas control module and a cathode tailstock.

[0017] The nesting cathode body, cathode head and cathode tailstock are all made of conductive metal materials; the ventilation module and gas control module are made of non-conductive materials; the shape of the cathode edge groove of the cathode head can be designed according to the shape of the processed parts, The width of the ventilation groove on the side of the cathode head and the thickness of the horizontal channel of the ventilation module can be adjusted according to the processing conditions.

[0018] Adopt the process of electrolytic processing workpiece of the present invention to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com