Double-barrel matching mortar tank

A mortar tank and storage tank technology, which is applied to batching batching instruments, batching weighing instruments, and raw material supply devices for sales, can solve problems such as increasing work difficulty, prolonging working time, reducing work efficiency, etc., to save transportation costs, Improve work efficiency and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

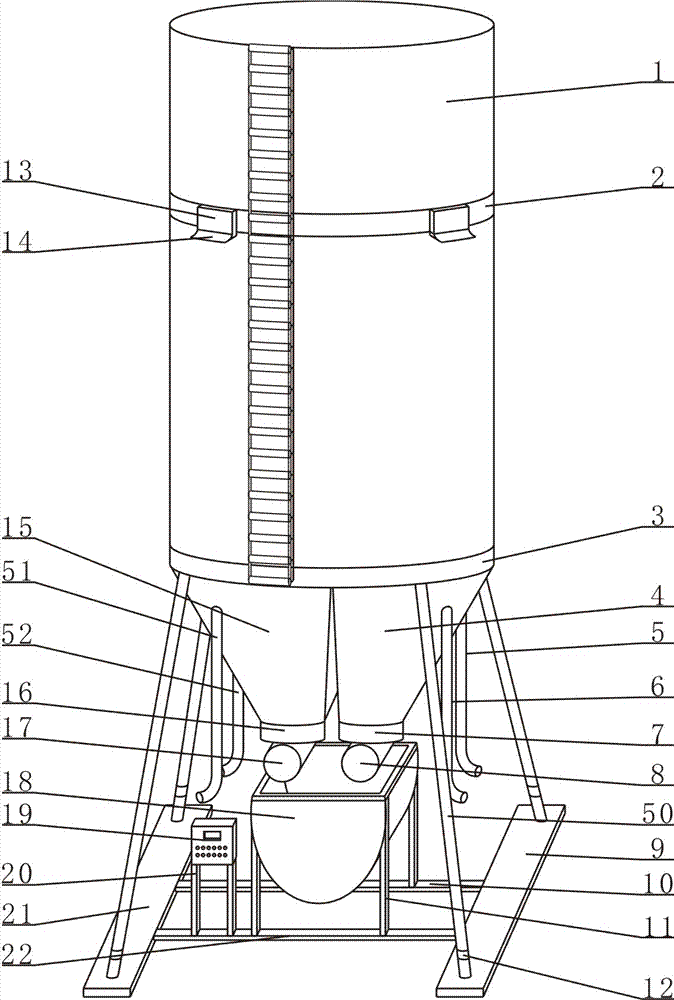

[0040] Embodiment 1, implement a kind of double-barrel proportioning mortar tank described in the present invention, when using, first place the bottom plate on the designated position, then set the bracket on the bottom plate, so that the storage tank can be used by the hoisting tool The hoisting device above the material tank 1 places the material storage tank 1 on the support. After the material storage tank 1 is placed, the aggregate cylinder and the powder material cylinder can be put into the aggregate cylinder and the powder material cylinder through the first material pipe 5 and the second material pipe 6 respectively. The feeder is installed on the top of the aggregate barrel and the distribution barrel, so that the controller can see the materials put in the aggregate barrel and the distribution barrel. When discharging, The aggregate cylinder and the distribution cylinder inject the aggregate and powder into the mixer 18 through the aggregate lower cylinder valve 7 a...

Embodiment 2

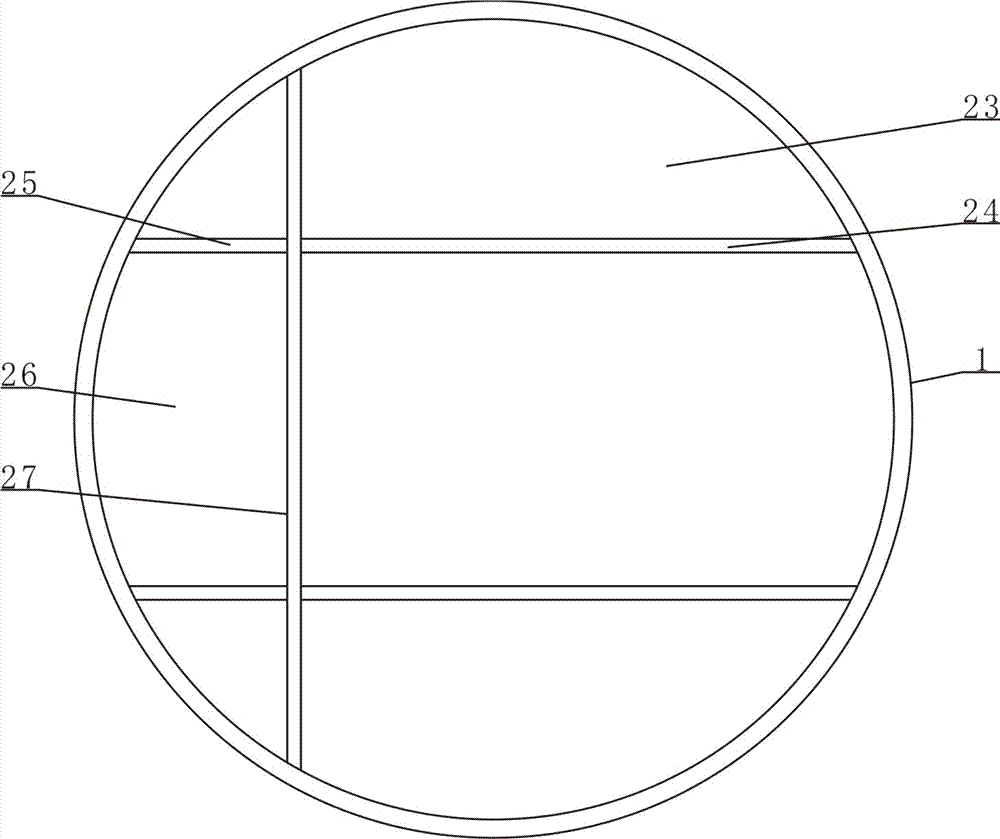

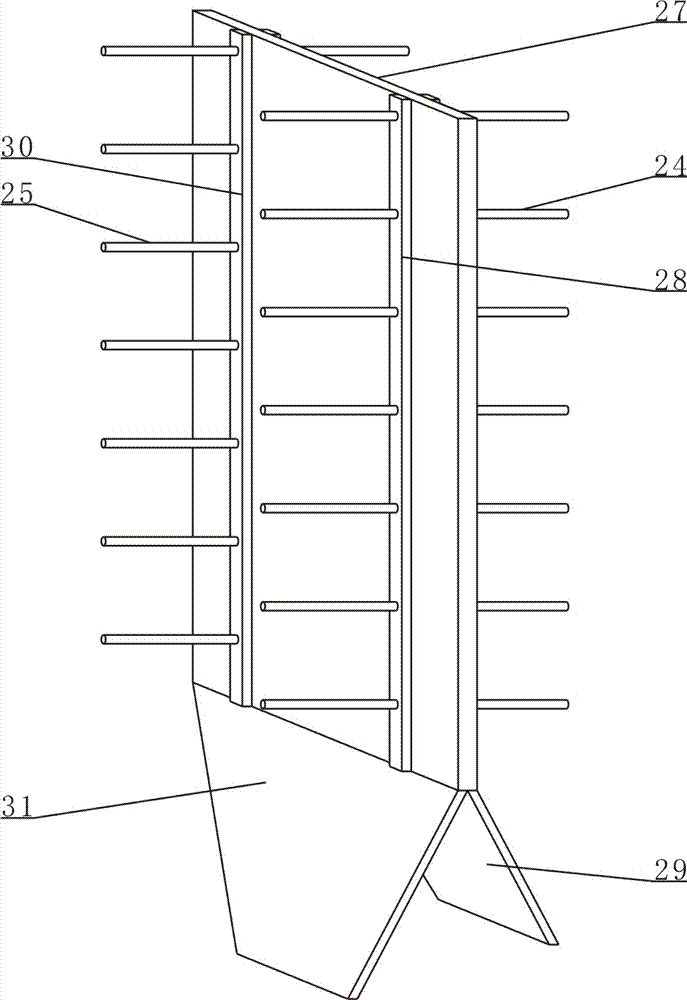

[0041] Embodiment 2, in conjunction with attached Figure 2-3 , implement a kind of double-cylinder proportioning mortar tank according to the present invention, the inner wall of the storage tank 1 is separated by a partition 27 to form an aggregate cylinder and a distribution cylinder, and the volume ratio of the aggregate cylinder and the distribution cylinder is 2 to 8 To any ratio of 4 to 6, since the storage tank 1 is relatively large, it needs to be supported by the support rod 25 and the support rod 24 of the aggregate cylinder, which prevents the gap between the aggregate cylinder and the distribution cylinder. The clapboard 27 is deformed, and the supporting rods 25 and the supporting rods 24 of the material cylinder are respectively fixed by the fixing rods on both sides of the clapboard 27, and the lower plate 29 of the material cylinder and the lower plate 31 of the material tube are arranged at the bottom of the clapboard 27. , so that the aggregate cylinder and ...

Embodiment 3

[0042] Embodiment 3, in conjunction with attached Figure 4 , to implement a kind of double cylinder proportioning mortar tank according to the present invention, the main raw material in the aggregate cylinder is sand, so it is completely ineffective for general valves in practice, because the sand has a certain humidity, so the sand The viscosity is very strong, and it is often necessary to knock the wall of the cylinder to discharge the material, and when the sand passes through the valve, the material is often not smoothly discharged. Therefore, the aggregate discharge valve 7 of this valve is a good solution. In order to avoid the difficult phenomenon of aggregate blanking, the filter rod 36 and the stirring shaft 38 in the aggregate lowering cylinder valve 7 can well unload the sand in the aggregate cylinder. When the stirring shaft 38 rotates, it drives the sand to proceed. material, and the stirring shaft 38 is set above the filter rod 36, and one end of the filter rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com