Method for preparing a conductive resin composition

A conductive resin and composition technology, applied in the field of preparation of conductive resin composition, can solve the problem of reducing the impact resistance, elongation, wear resistance and mechanical properties of thermoplastic resins, product commercialization restrictions, and inability to achieve electrical conductivity, etc. problems, to achieve the effect of preventing the reduction of mechanical properties and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

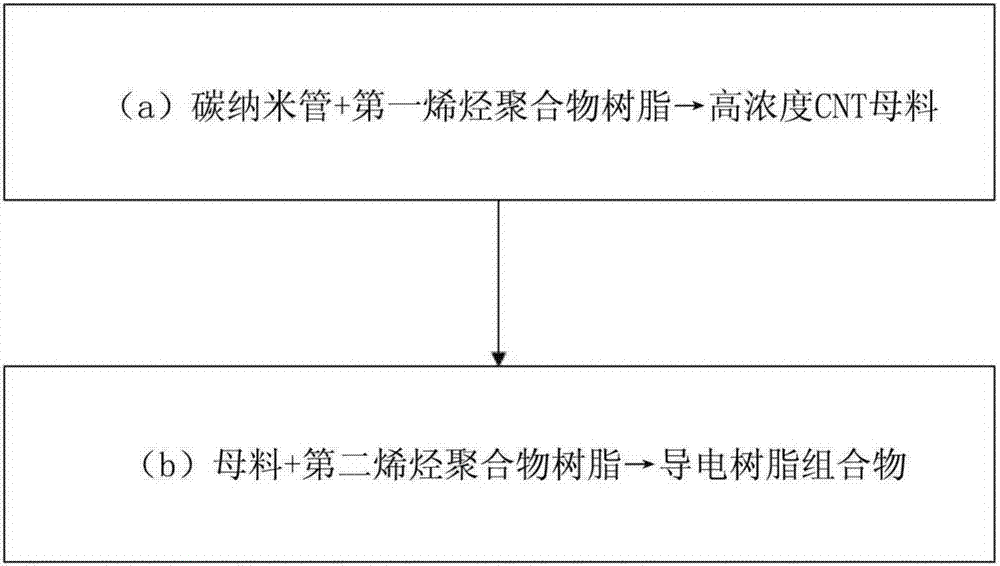

[0032] figure 1 A method for preparing a conductive resin composition according to an aspect of the present invention is schematically shown. refer to figure 1 , The preparation method of the conductive resin composition according to one aspect of the present invention may include: step (a), preparing a masterbatch by extruding carbon nanotubes and a first olefin polymer resin; and step (b), mixing the masterbatch and second olefin polymer resin.

[0033] The conductive resin composition can basically consist of a polymer resin having a certain level of mechanical properties and moldability, and a conductive material that can impart conductivity to the polymer resin, such as metals and other inorganic substances. In order to prepare the above-mentioned conductive resin composition, an accompanying process for mixing the polymer resin and the conductive material is required.

[0034] In order to improve the conductivity of the existing conductive resin composition, a techniq...

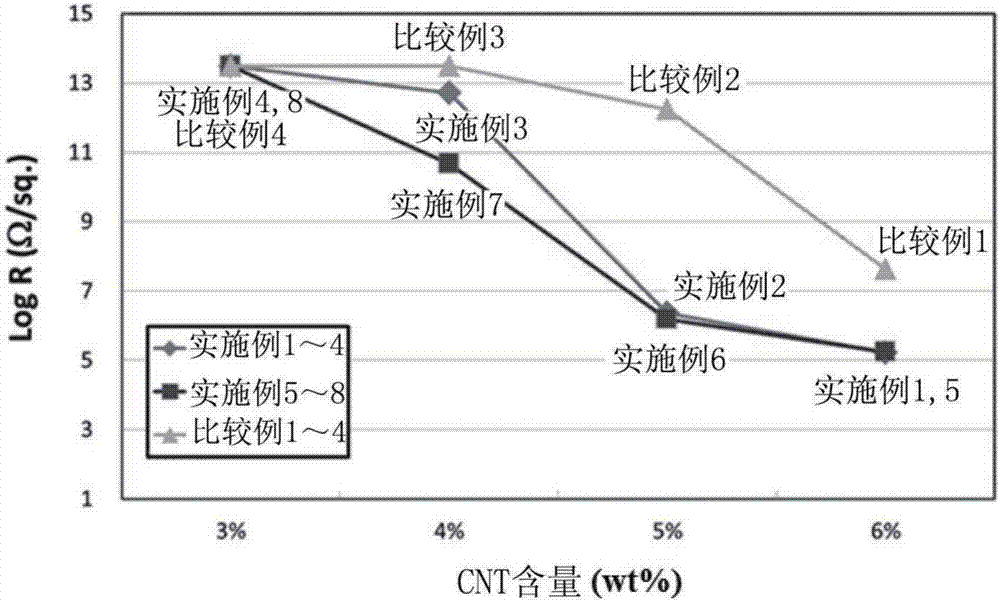

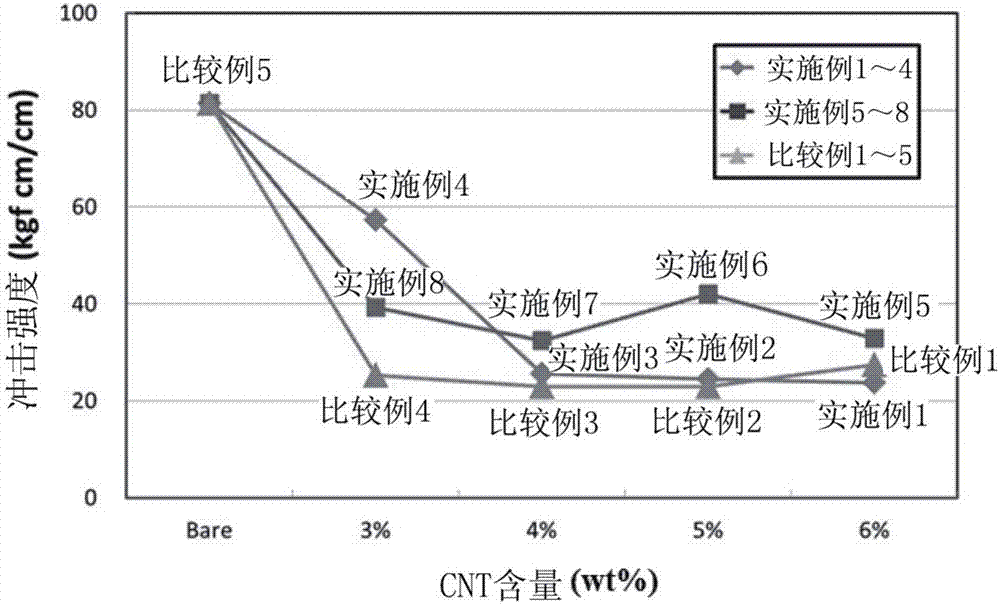

Embodiment 1

[0068] Put multi-walled carbon nanotubes (MWCNT) into the side feeder of the twin-screw extruder, and put polyethylene (HDPE, melt index 5.0g / 10min, ASTMD 1238) into the main hopper at a speed of 25kg / hr, Melt-kneading was then carried out under the conditions of a kneading speed of 200 rpm and a processing temperature of 230° C., thereby preparing a masterbatch having a carbon nanotube content of 10% by weight.

[0069] The prepared masterbatch and different types of polyethylene (HDPE, melt index 0.3g / 10min, ASTM D1238) were put into the twin-screw extruder at the same time, and the kneading speed was 200rpm and the processing temperature was 250°C. It was melt-kneaded to prepare a resin composition having a carbon nanotube content of 6% by weight.

Embodiment 2

[0071] Except that the content of carbon nanotubes contained in the masterbatch was adjusted to 10% by weight, and the content of carbon nanotubes contained in the resin composition was adjusted to 5% by weight, the rest were the same as in Example 1. The resin composition was prepared by the method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com