Measuring device for combustion propagation velocity of liquid alkali metal

A technology of propagation velocity and measuring device, which is applied in chemical analysis by combustion, etc., can solve problems such as ignoring the interaction of sodium droplets, and achieve the effects of accurate and reliable structure, increased reliability and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

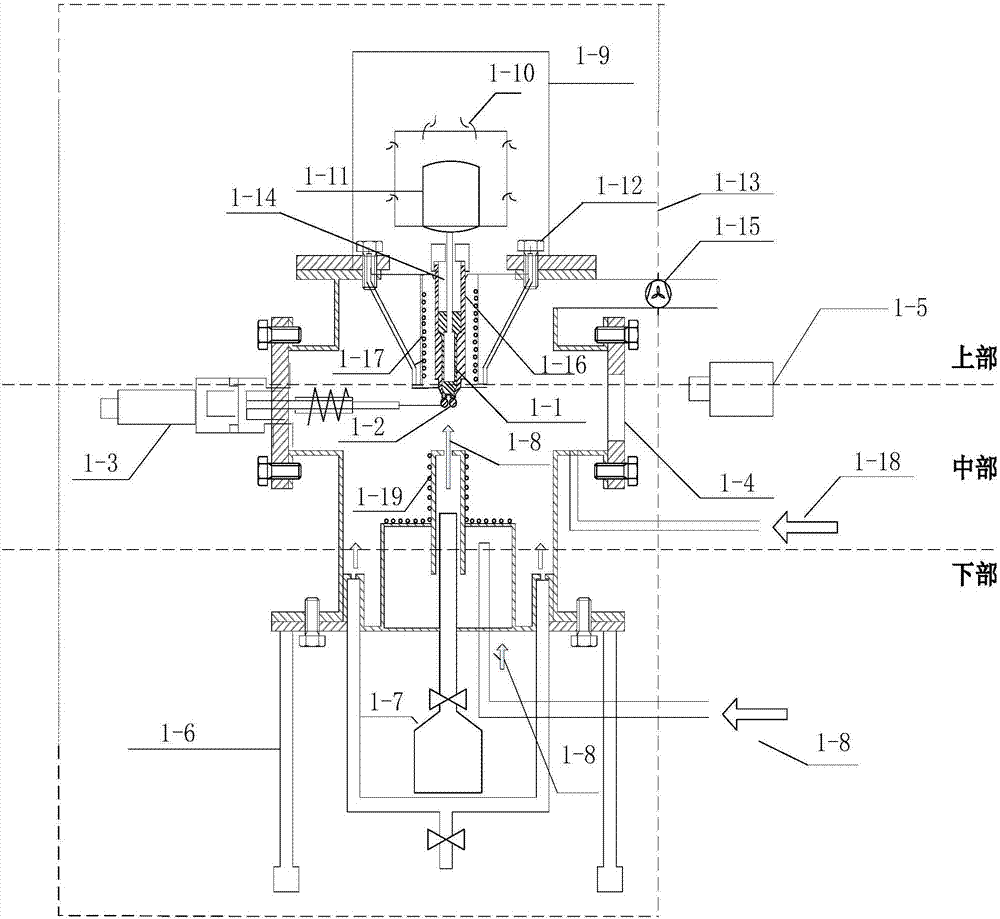

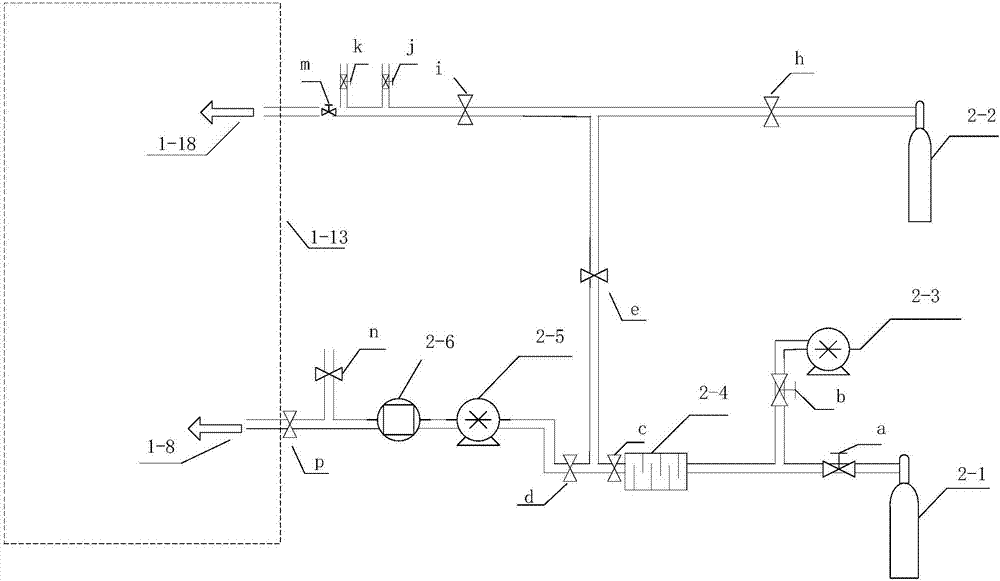

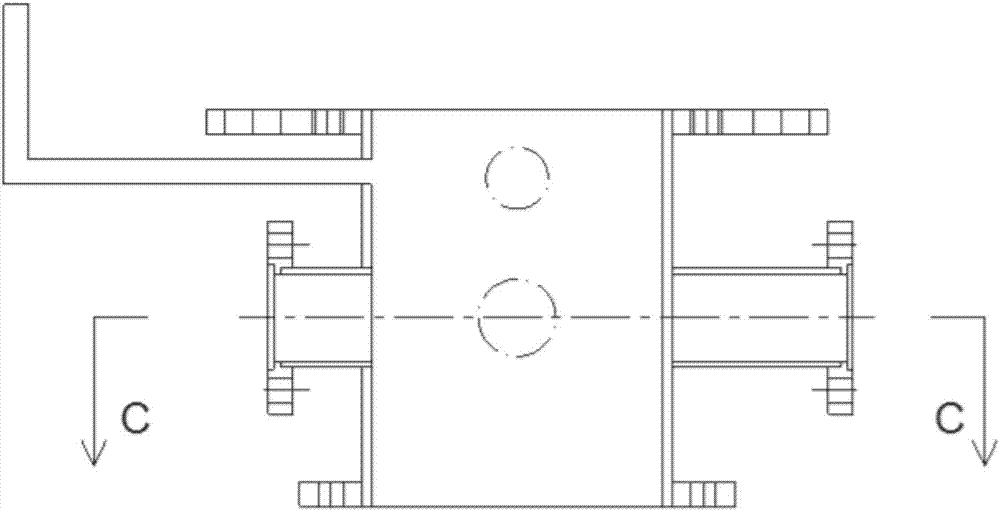

[0026] combine Figure 1-8 , the present invention includes a combustion container, a combustion crucible, a combustion rod, a heating device, and an electric control box. The combustion vessel used in the experiment is divided into upper, middle and lower parts. The upper part is a heating combustion device, a crucible 1-16 with double nozzles is placed in the upper chamber, and there are electric heating wires 1-17 around it to heat it. Just above the opening of the crucible 1-16, there is a combustion rod 1-14 for extruding liquid sodium 1-1, and the combustion rod 1-14 is pushed up and down by a motor 1-11 positioned above it. The plexiglass cover 1-9 on the top of the container makes the liquid sodium 1-1 in the crucible in the protective gas to avoid oxidation. The middle part of the combustion container is the combustion chamber and the observation chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com