Direct-driving magnetic-coupling type harmonic motor

A magnetic coupling and harmonic motor technology, applied in the direction of motors, magnetic circuits, electromechanical devices, etc., can solve the problems of difficult maintenance of the motor-gear transmission system, large motor volume, low output efficiency, etc., to achieve difficult maintenance and high application value, the effect of high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

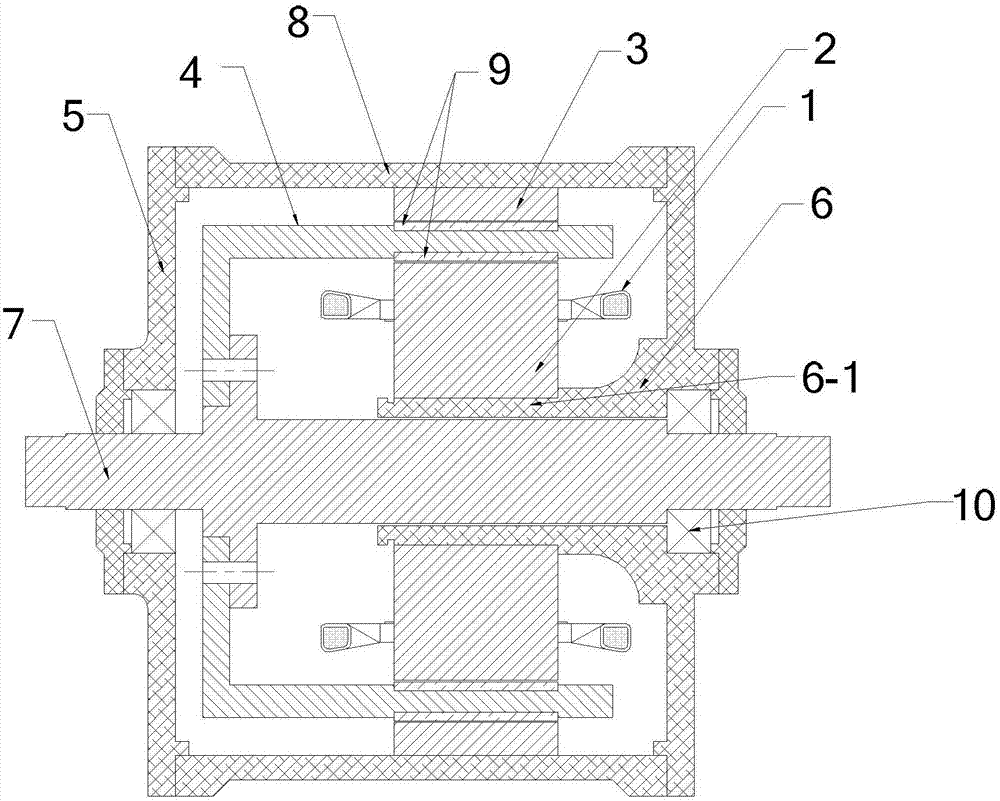

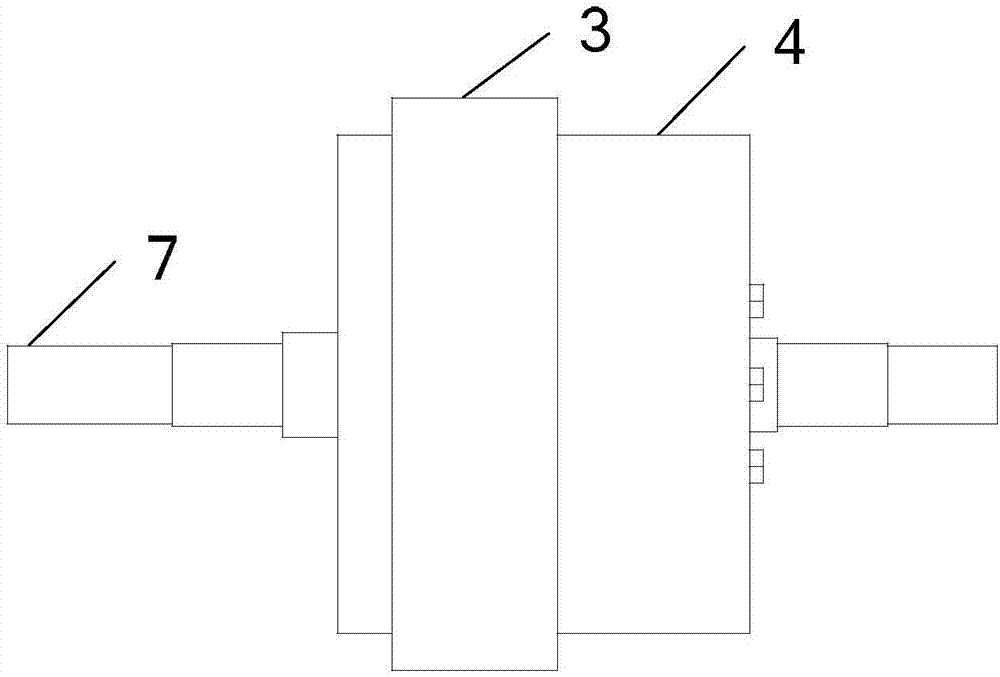

[0035] Specific implementation mode one: see Figure 1 to Figure 19 Describe this embodiment, the direct-drive magnetic coupling type harmonic motor described in this embodiment includes armature winding 1, inner stator 2, outer stator 3, cup-shaped rotor 4, left end cover 5, right end cover 6, rotor Output shaft 7, casing 8 and magnetic steel 9;

[0036] In the radial direction of the rotor output shaft 7, the inner stator 2, the cup-shaped rotor 4, the outer stator 3 and the casing 8 are sheathed in sequence from the inside to the outside. gap;

[0037] The left end cover 5 and the right end cover 6 are respectively covered on the left and right end surfaces of the casing 8, and both are rotationally connected with the rotor output shaft 7 through the bearing 10;

[0038] The cup opening of the cup-shaped rotor 4 faces the right end cover 6, and the cup bottom of the cup-shaped rotor 4 is fixedly connected with the rotor output shaft 7;

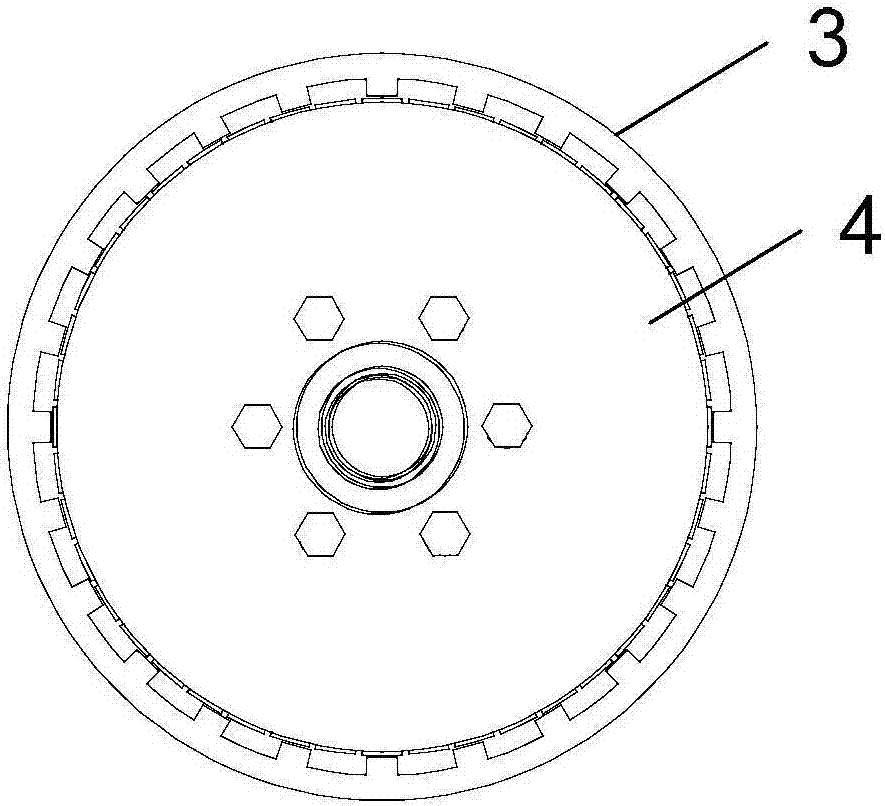

[0039] The inner and outer walls ...

specific Embodiment approach 2

[0046] Specific implementation mode two: see Figure 1 to Figure 19Describe this embodiment, the difference between this embodiment and the direct-drive magnetic coupling harmonic motor described in Embodiment 1 is that the magnetic steel 9 on the inner and outer walls of the cup-shaped rotor 4 is respectively connected with the inner stator 2 is set opposite to the outer stator 3, and the axial length of the magnetic steel 9 is greater than or equal to the axial lengths of the inner stator 2 and the outer stator 3.

specific Embodiment approach 3

[0047] Specific implementation mode three: see Figure 1 to Figure 19 This embodiment is described. The difference between this embodiment and the direct-drive magnetic coupling harmonic motor described in Embodiment 1 is that the teeth on the outer stator 3 are arranged opposite to the tooth slots of the inner stator 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com