Vertical rotor magnetic suspension windmill generator

A technology of wind power generator and magnetic levitation, which is applied in the direction of wind power generator components, wind power engine, wind power motor combination, etc. It can solve the problems of unseen surplus space, large consumption of metal materials, high starting speed, etc., and achieve weight reduction and reduction The effect of reducing the component area and wind rotor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

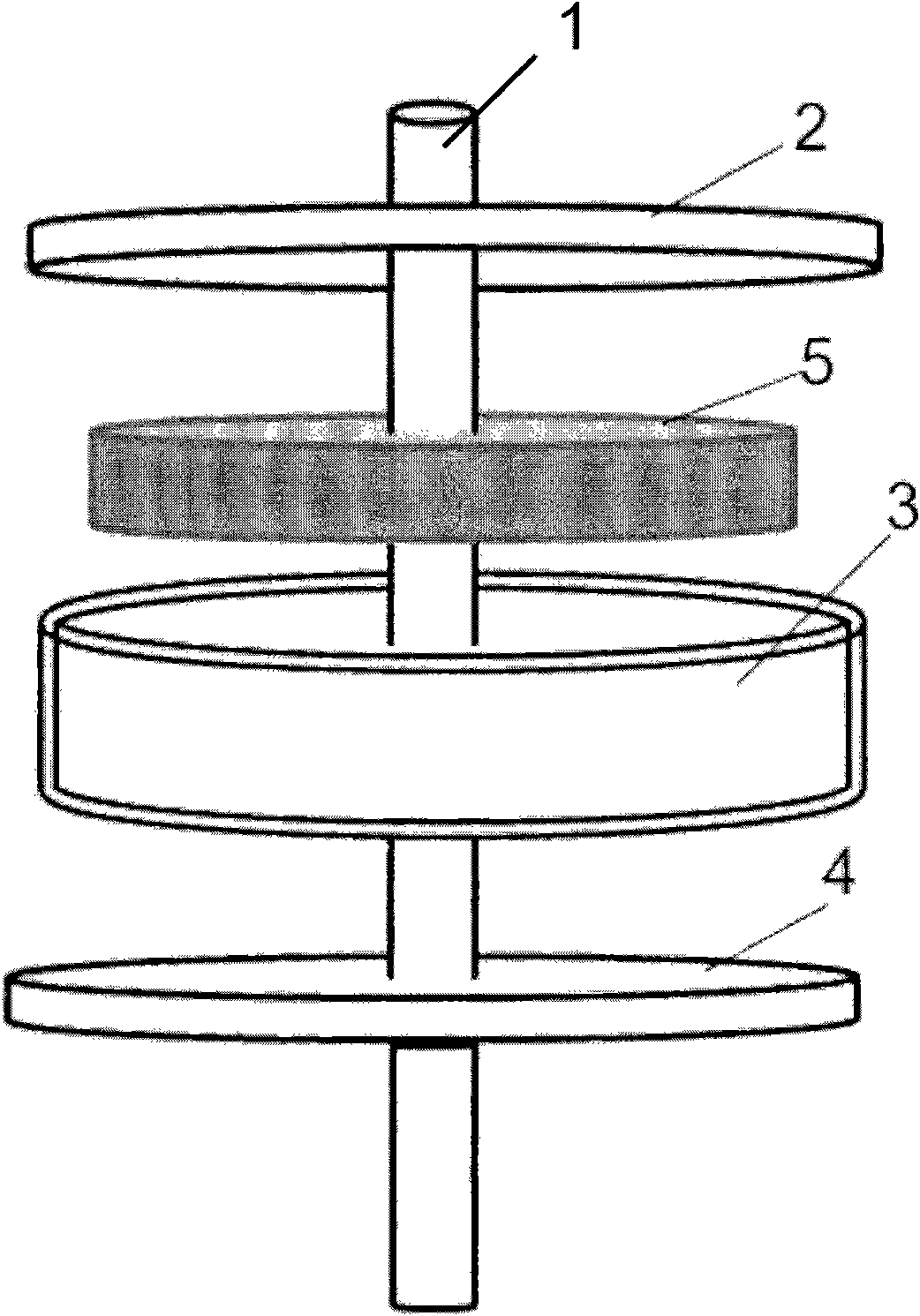

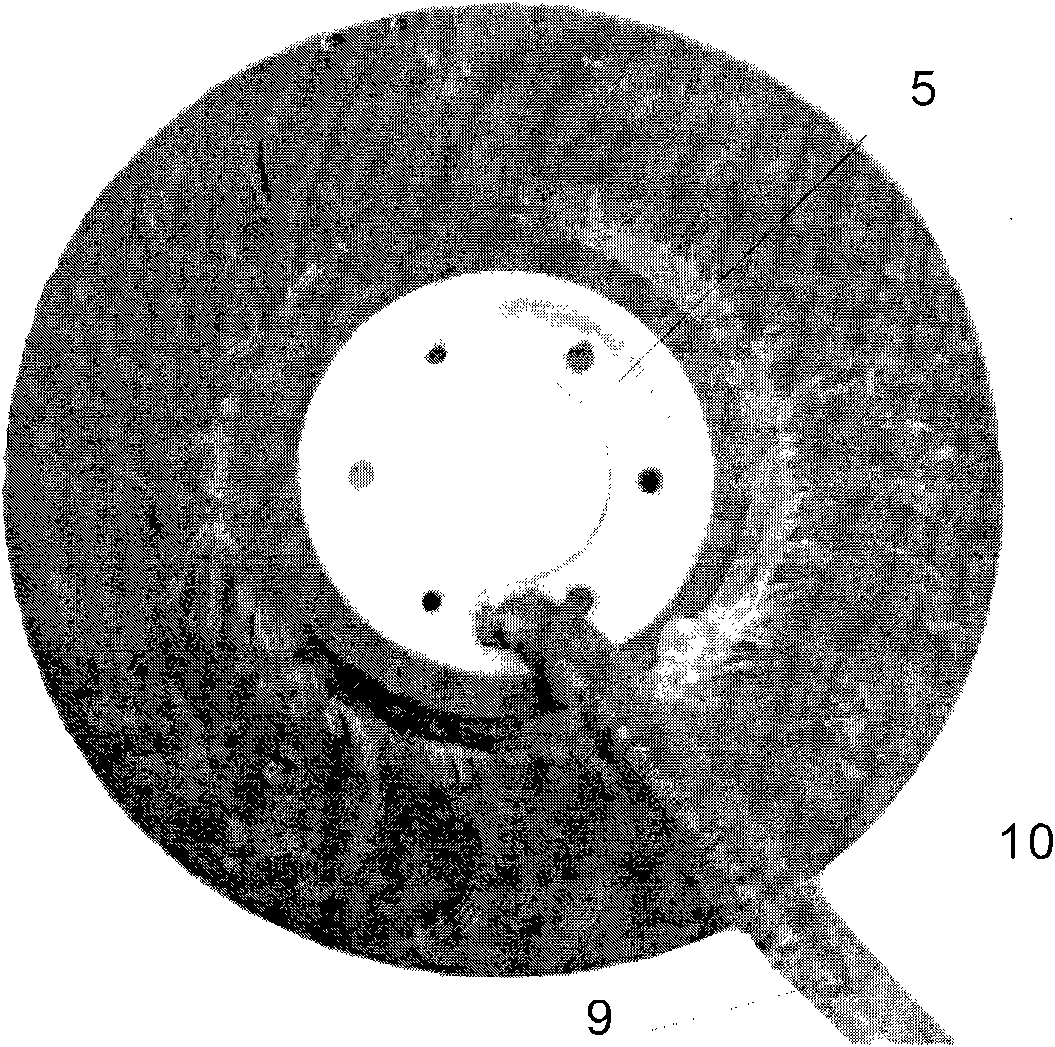

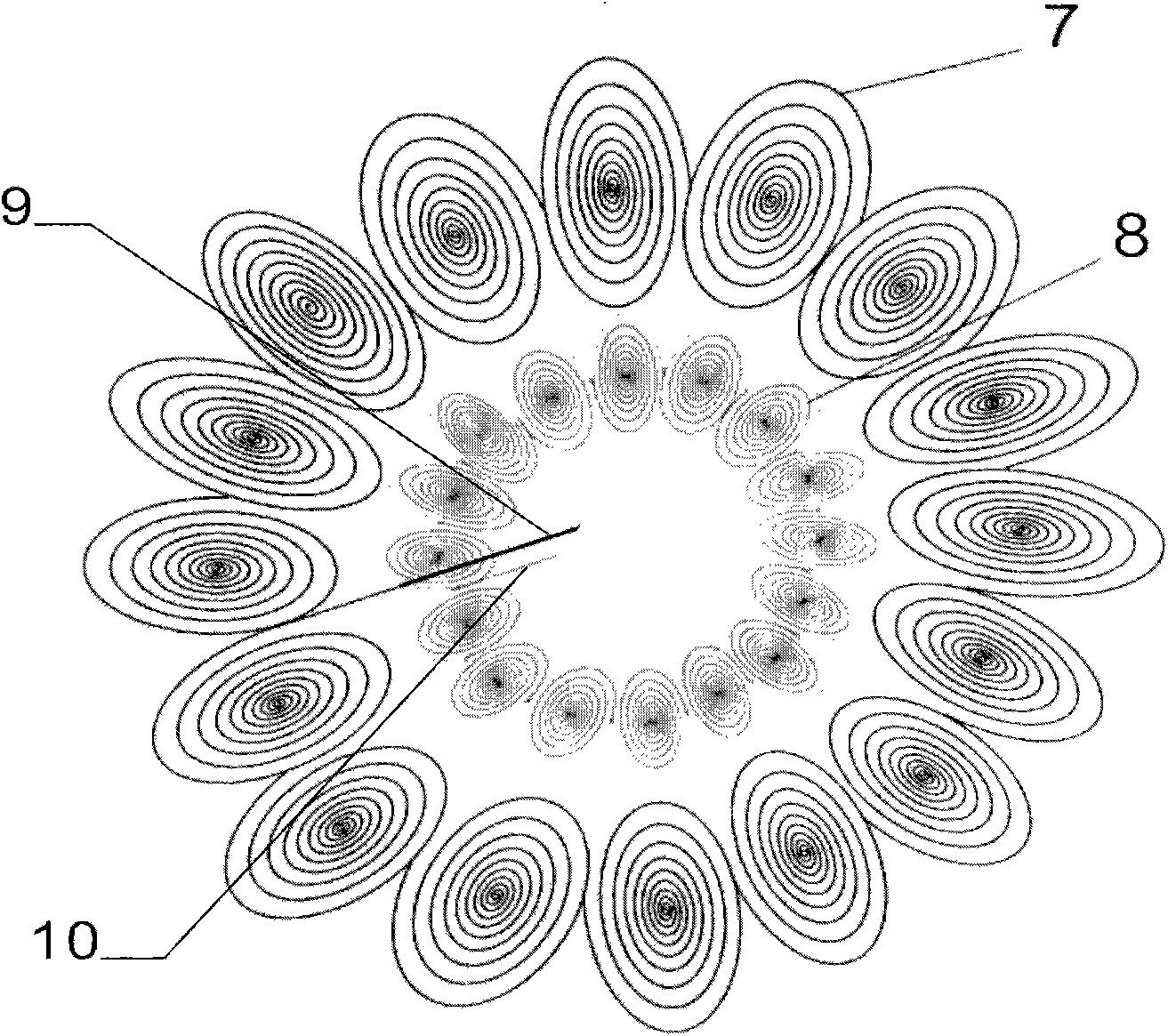

[0025] a kind of like Figure 1~4 The shown direct-drive outer rotor permanent magnet synchronous vertical axis magnetic levitation wind turbine includes a main shaft 1, a disc-shaped casing composed of an upper casing cover 2, a cylindrical casing 3 with a short axial dimension in the middle, and a lower casing cover 4, and a stator. 5 and the outer rotor, the stator 5 is arranged in the disc-shaped housing, the outer rotor is an outer rotor composed of the upper case cover 2 and the lower case cover 4 and is connected with the main shaft 1 through interference fit, the upper case cover 2 and the lower case cover 4 There are outer trapezoidal pole grooves on the inner side of the near outer circumference of the 16 fan-shaped areas divided equally according to the set number of magnetic poles on the side, and a magnetic pole 6 formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com