Alternating-current generator and stator thereof

A technology for alternators and stators, which is applied to the static parts of the magnetic circuit, and the shape/style/structure of the magnetic circuit. efficiency, cost savings, and copper wire savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

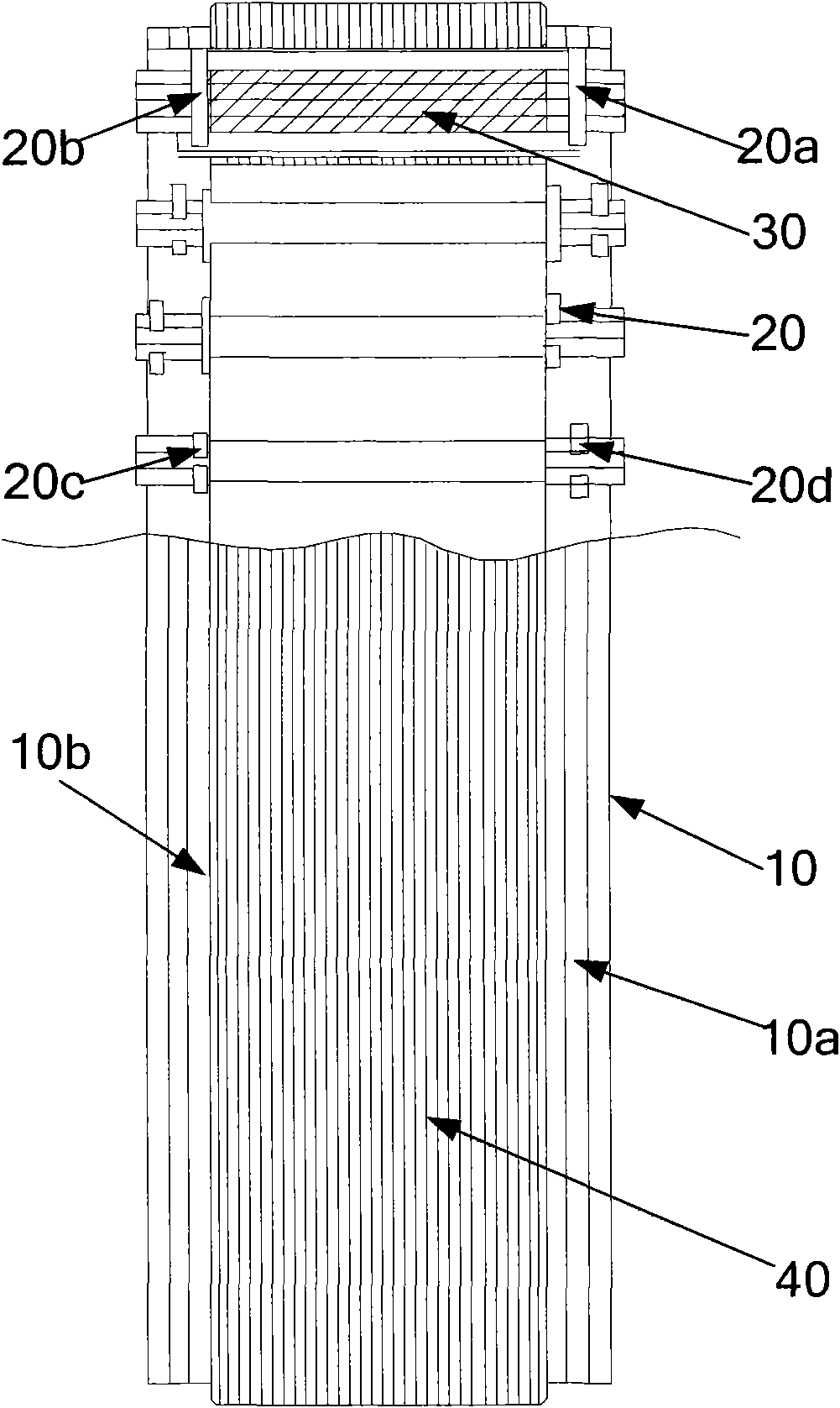

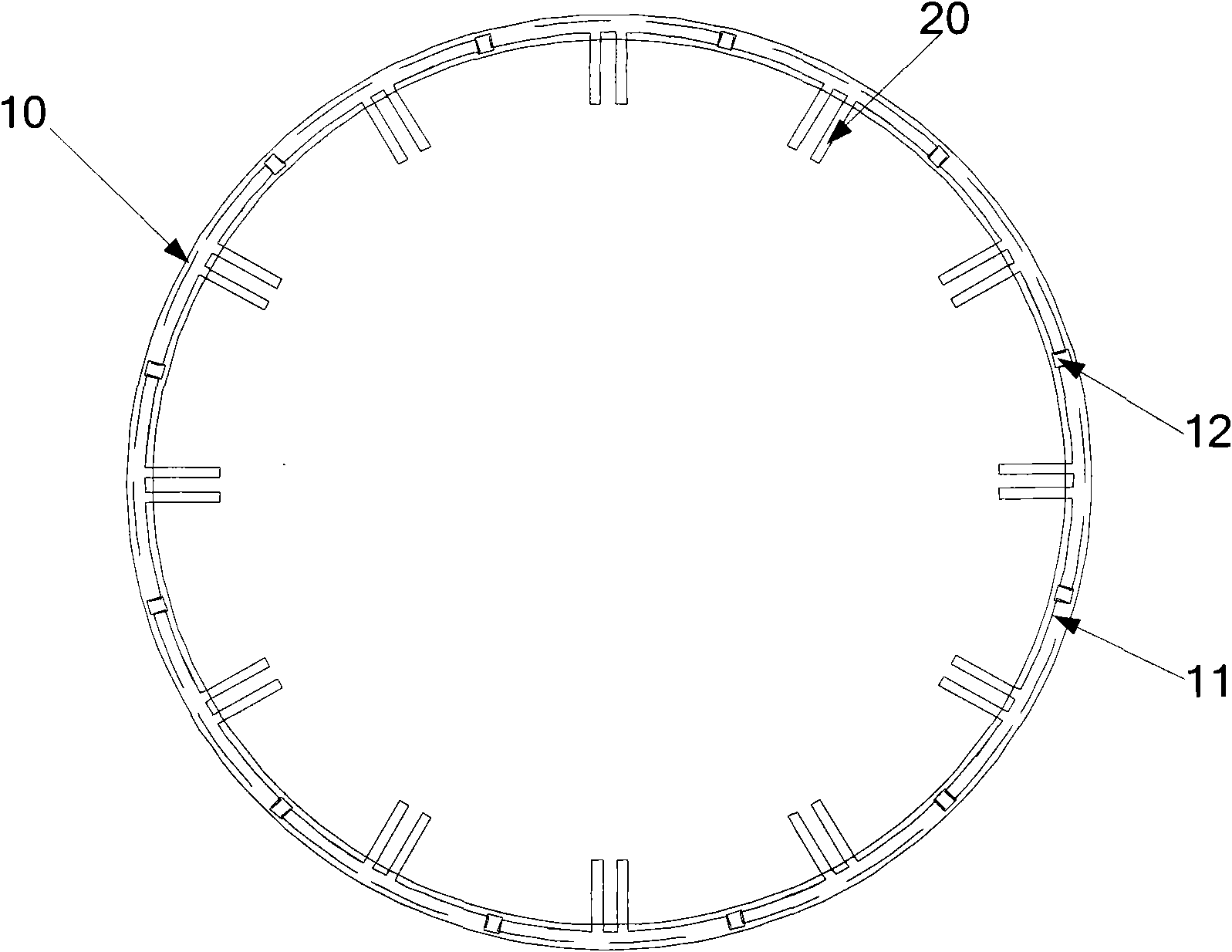

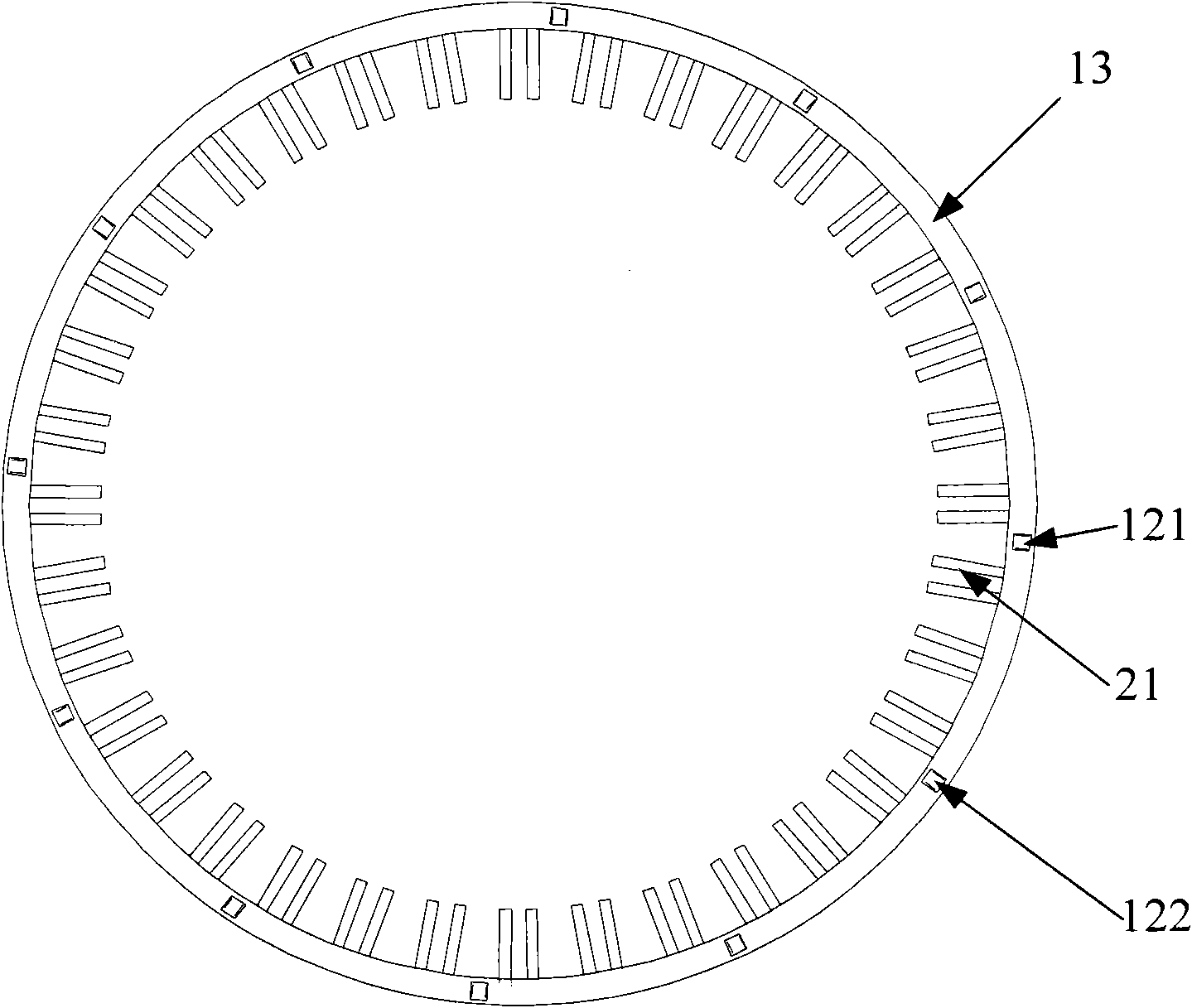

[0023] Attached below Figures 1 to 4 as well as Figure 6 A first embodiment of the alternator stator according to the present invention will be described in detail.

[0024] Such as figure 1 and Figure 4 As shown, an alternator stator includes a stator core 40, and the alternator stator also includes: a ring circuit board 10, a plurality of ring circuit boards 10 are symmetrically distributed on both sides of the stator core 40; a plurality of clamps 20, The wire clip 20 is located on the ring circuit board 10 and is electrically connected with the ring circuit board 10; a plurality of magnetic induction cutting parts 30, the two ends of each magnetic induction cutting part 30 are respectively located in the wire clip 20, and are connected with the card The clip 20 is electrically connected. Wherein, the magnetic induction l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com