Microelectromechanical system (MEMS) package

A technology of packaging and components, applied in the direction of optical components, semiconductor devices, electrical solid devices, etc., can solve the problem of not being able to manufacture control ICs

Inactive Publication Date: 2017-08-29

AT & S AUSTRIA TECH & SYSTTECHN AKTIENGES

View PDF7 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These further developments relative to the original state lead to the inability to fabricate the control IC on the same substrate as the MEMS part itself

Even with the in

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

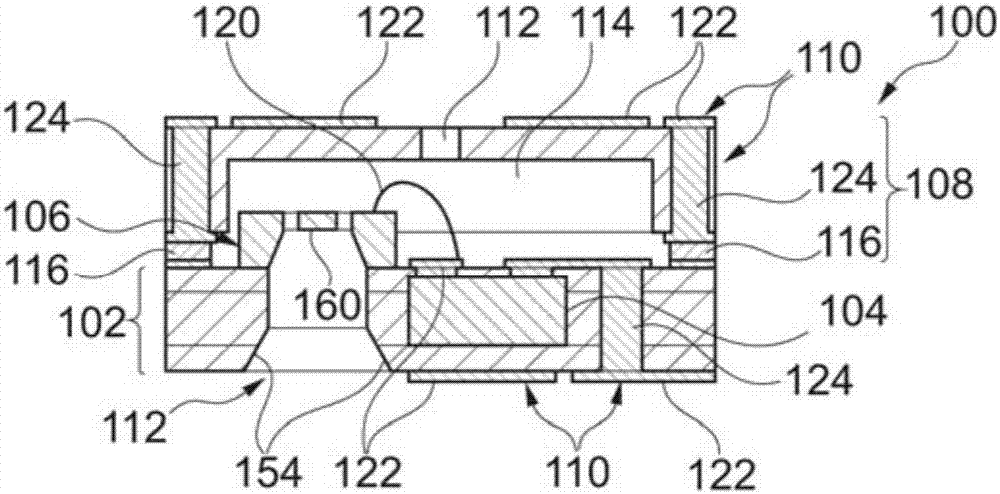

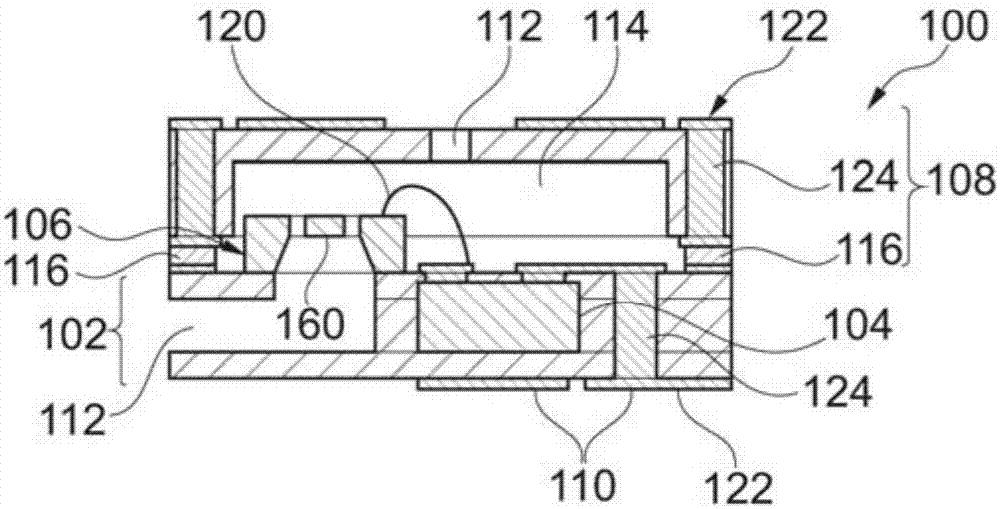

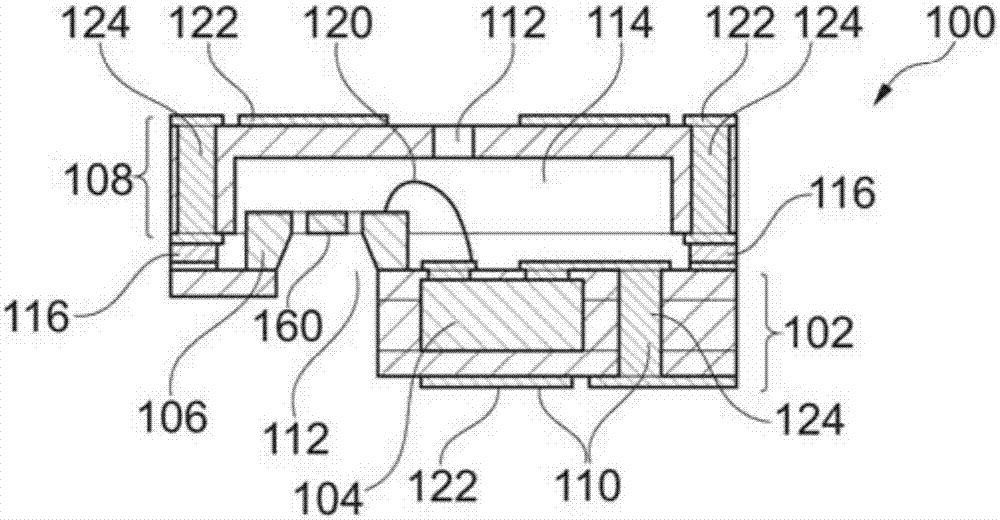

The invention relates to a package comprising a base structure (102) which comprises an electrically insulating material and/or an electrically conductive contact structure (110), an electronic component (104) which is embedded in the base structure (102) or on the base structure (102), a microelectromechanical system (MEMS) component (106) and a cover structure (108) which is mounted on the base structure (102) to at least partially cover the MEMS component (106)

Description

technical field [0001] The invention relates to a package, an arrangement and a method for manufacturing an electronic device. Background technique [0002] Firstly, MEMS components (microelectromechanical systems, micro-electromechanical systems) are fabricated with traditional semiconductor tools. Special requirements regarding eg dimensions, materials, shapes etc. lead to the development of specialized processes. These further developments over the original state resulted in the inability to fabricate control ICs on the same substrate as the MEMS components themselves. Even with the introduction of CMOS-compatible processes (which enabled single-chip MEMS / ICs), the vast majority of MEMS applications separate the sensor / actuator from the control system. With the trend of progress towards smaller form factors and increased efficiency at lower cost, there is room for further developments in view of heterogeneous integration. Contents of the invention [0003] It is an o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B81C1/00B81C3/00B81B7/02H04R19/00H04R19/04

CPCB81B7/02B81C1/0023B81C3/008H04R19/005H04R19/04B81B2201/0257B81B2207/096B81B2207/095H04R2201/003H01L2224/48091H01L2924/15151H01L2924/00014B81B7/0061B81B2207/012B81C2203/0785H04R19/02

Inventor 马库斯·莱特格布尼克·雷诺·贝佐特

Owner AT & S AUSTRIA TECH & SYSTTECHN AKTIENGES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com