Smoking machine

A smoking machine and smoking technology, which is applied in the field of smoking machines, can solve the problem of difficulty in determining the completion time of smoke exhaust, and achieve the effects of ensuring continuity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

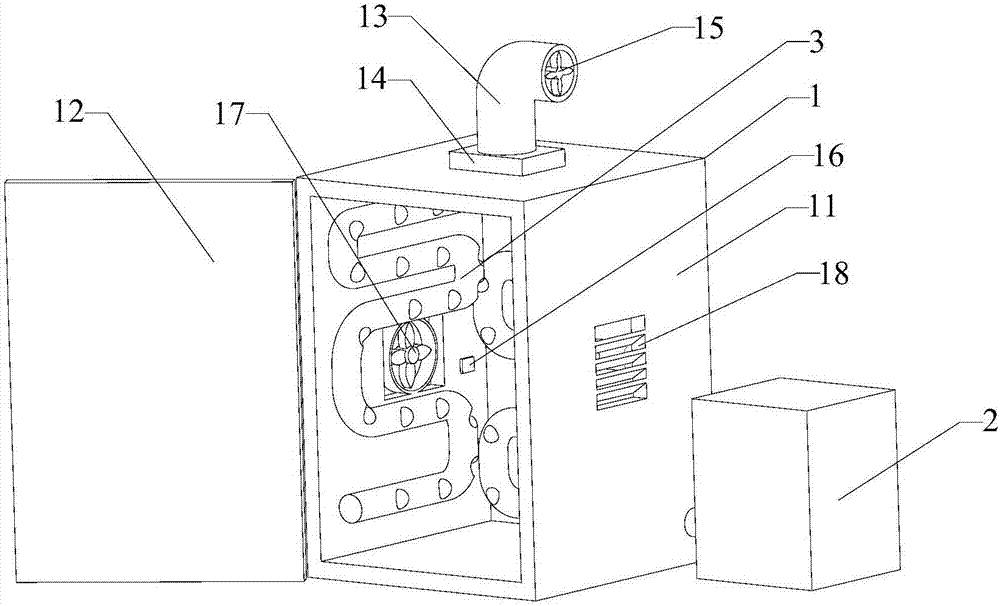

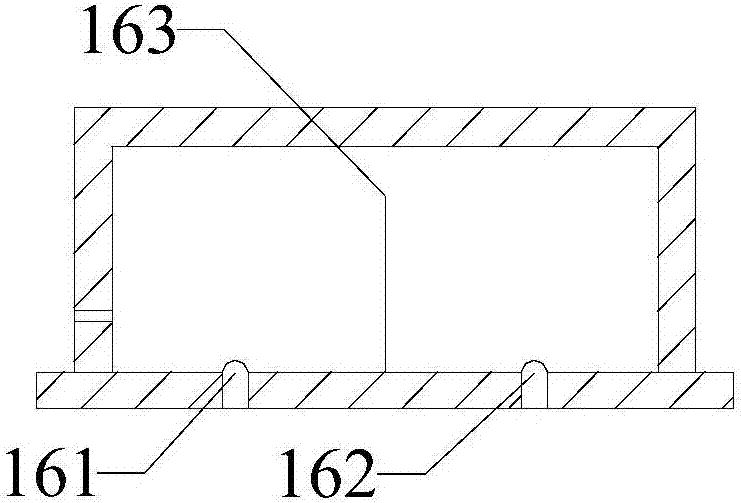

[0053] Please refer to the figure, a smoker includes a smoker 1 and a smoker 2; the smoker 1 is connected to the smoker 2 through a smoker pipe 3; the smoker 1 includes a cabinet body 11, a cabinet Door 12, smoke exhaust pipe 13, smoke exhaust pipe valve 14, exhaust fan 15, control panel, smoke sensor 16 and alarm device; the shape of the cabinet body 11 is rectangular, and the inner wall of the cabinet body 11 is provided with a smoke sensor 16, so The outer wall of the cabinet body 11 is provided with an alarm device, and the smoke sensor 16 is electrically connected to the alarm device; the upper part of the cabinet body 11 is connected to a smoke exhaust pipe 13, and the smoke exhaust pipe 13 is provided with a smoke exhaust pipe valve 14, so The exhaust pipe 13 is provided with an exhaust fan 15, the exhaust pipe valve 14 is electrically connected to the smoke sensor 16, the exhaust fan 15 is electrically connected to the smoke sensor 16, and the outer surface of the cabin...

Embodiment 2

[0055] A fumigator, the inner section of the cabinet of the fumigating pipe 3 is provided with an opening at intervals of 20 cm; other features are the same as in embodiment 1.

Embodiment 3

[0057] A fumigator, wherein an opening is arranged at intervals of 15 cm in the cabinet inner section of the fumigating pipeline 3 ; other features are the same as those in Embodiment 1.

[0058] To sum up, the smoking furnace provided by the present invention is provided with a smoke sensor inside the cabinet and an alarm device electrically connected to the smoke sensor outside the cabinet. When the smoke in the cabinet is emptied, the alarm device will remind workers in time Open the cabinet door to smoke the next batch of food; on the one hand, it ensures the continuity of the smoking process, so that when the smoker needs to process a large amount of food, it can work without interruption and improve production efficiency; on the other hand, it ensures In order to open the cabinet door, the smoke in the cabinet has been evacuated, which will not pollute the closed processing workshop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com