A high-efficiency plywood heat press machine

A hot press and plywood technology, which is applied to plywood presses, veneer presses, manufacturing tools, etc., can solve the problems of template dry glue, high labor intensity, and affecting the pass rate, etc., and achieve the effect of accurate and stable positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solutions of the present invention, the following specific embodiments are described in detail.

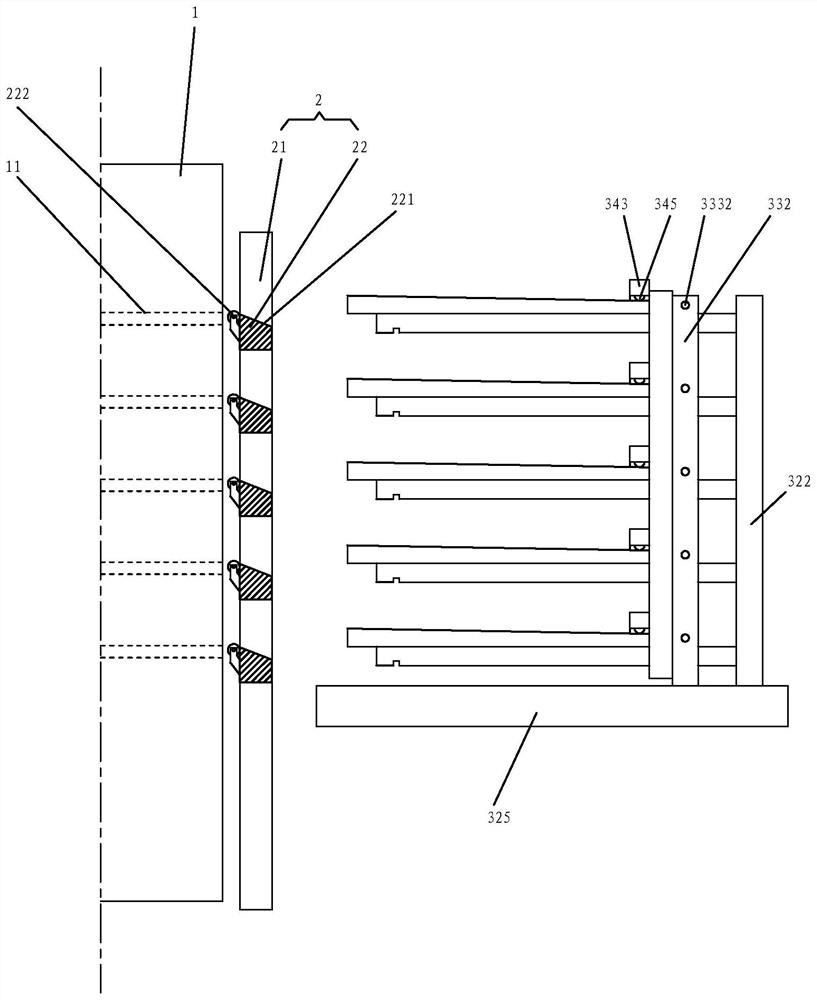

[0048] A high-efficiency plywood hot press of the present invention, such as Figure 1-14 As shown, it includes a hot press main body 1 and a conveying device 3 for conveying template blanks to the hot press main body 1;

[0049] The main body 1 of the heating press includes a multi-layer heating platen 11, and a connecting device 2 connected with the conveying device 3;

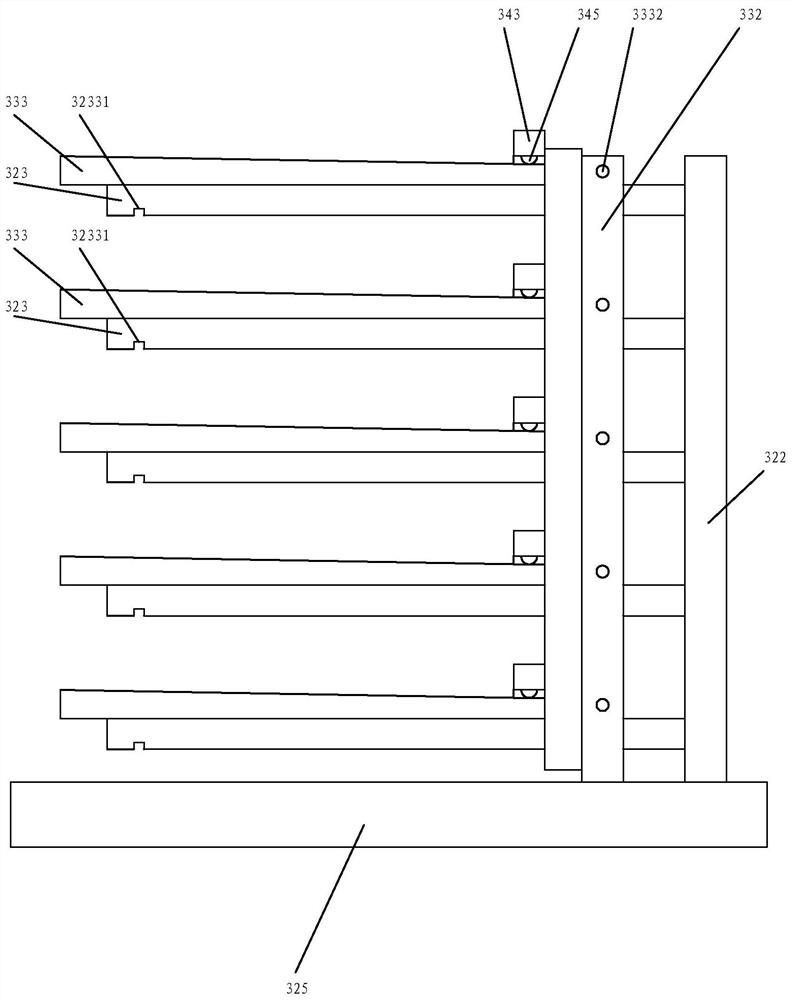

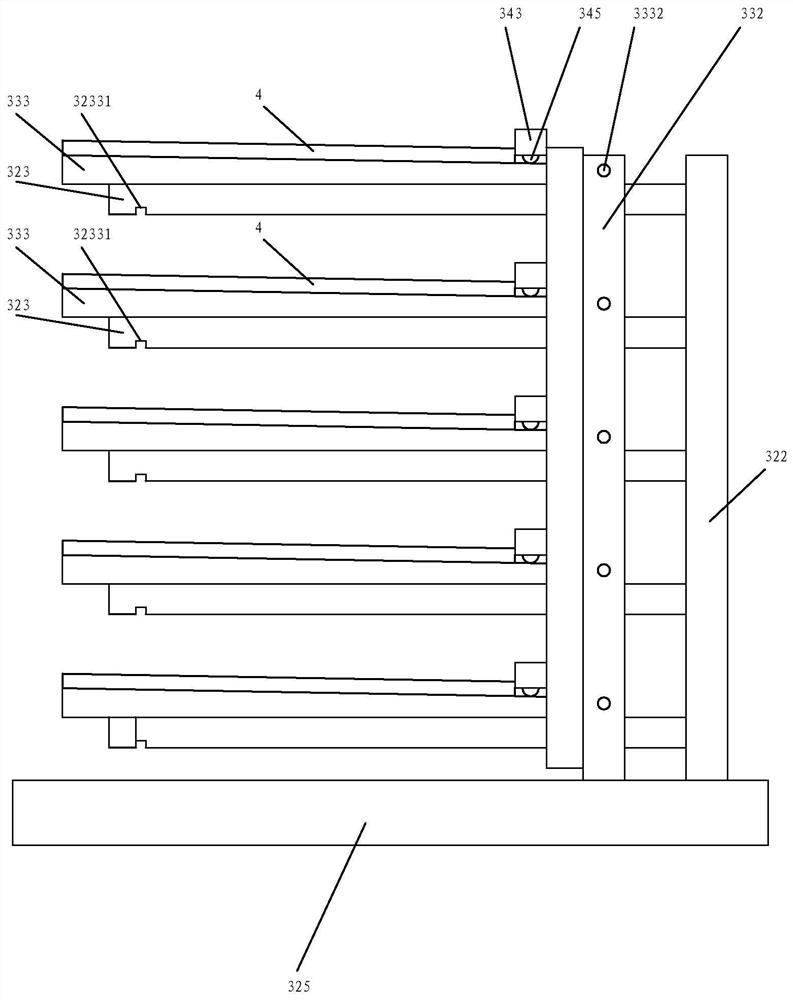

[0050] The conveying device 3 includes a movable base 31 , a movable bracket 32 arranged on the base 31 , a movable carrier 33 arranged on the movable bracket 32 to carry the multi-layer template blank 4 , and an abutment for abutting the template blank 4 . top part 34;

[0051] The moving bracket 32 includes a first support column 321 , a second support column 322 , and a plurality of the first support column 321 and the second support column 322 from top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com