A low-carbon plywood processing line

A plywood and assembly line technology, used in plywood presses, wood processing appliances, veneer presses, etc., can solve the problems of template blank dry glue, high labor intensity, affecting the pass rate, etc., and achieve the effect of accurate and stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further explain the technical solutions of the present invention, the following specific embodiments are described in detail.

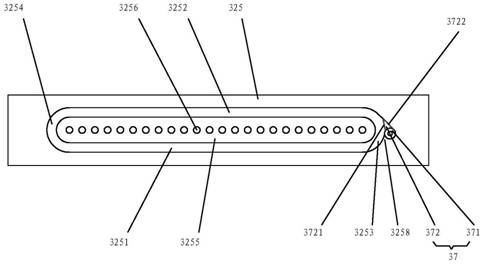

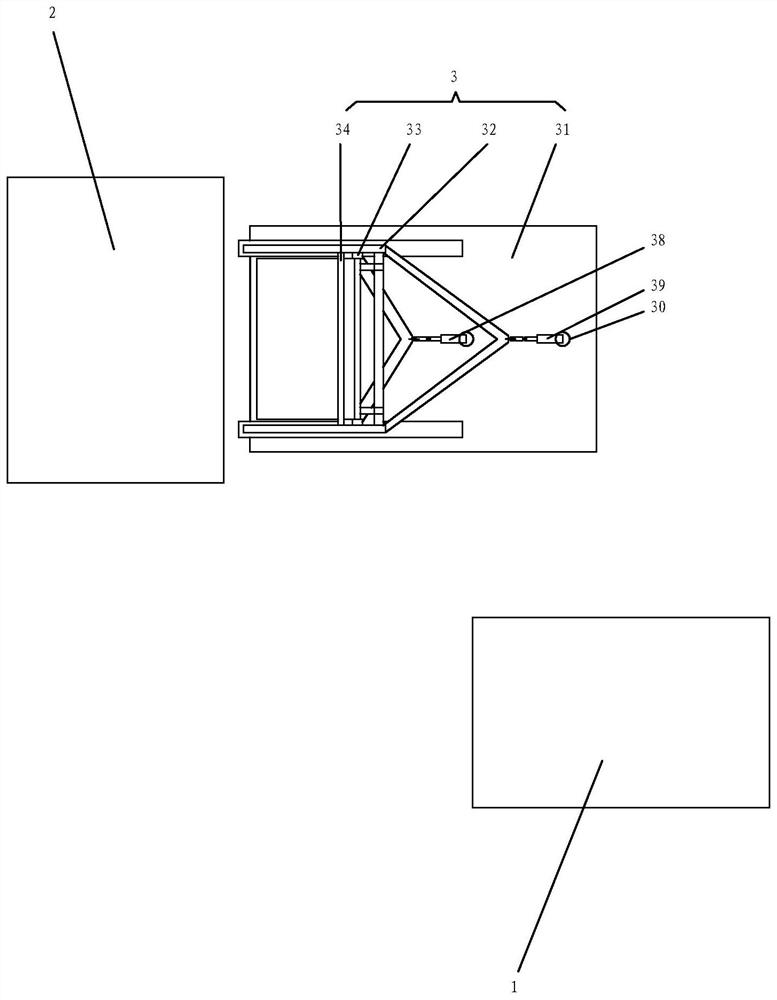

[0047] A low-carbon plywood processing line of the present invention, such as Figure 1-14 As shown, it includes a pre-pressing device 1 for pre-pressing the template blank 4 upstream, a hot-pressing device 2 for hot-pressing the template blank 4 downstream, and a feeding device upstream of the pre-pressing device 1 for feeding, and Between the pre-pressing device 1 and the hot-pressing device 2, the template blank 4 on the pre-pressing device 1 is transferred to the transfer device 3 on the hot-pressing device 2;

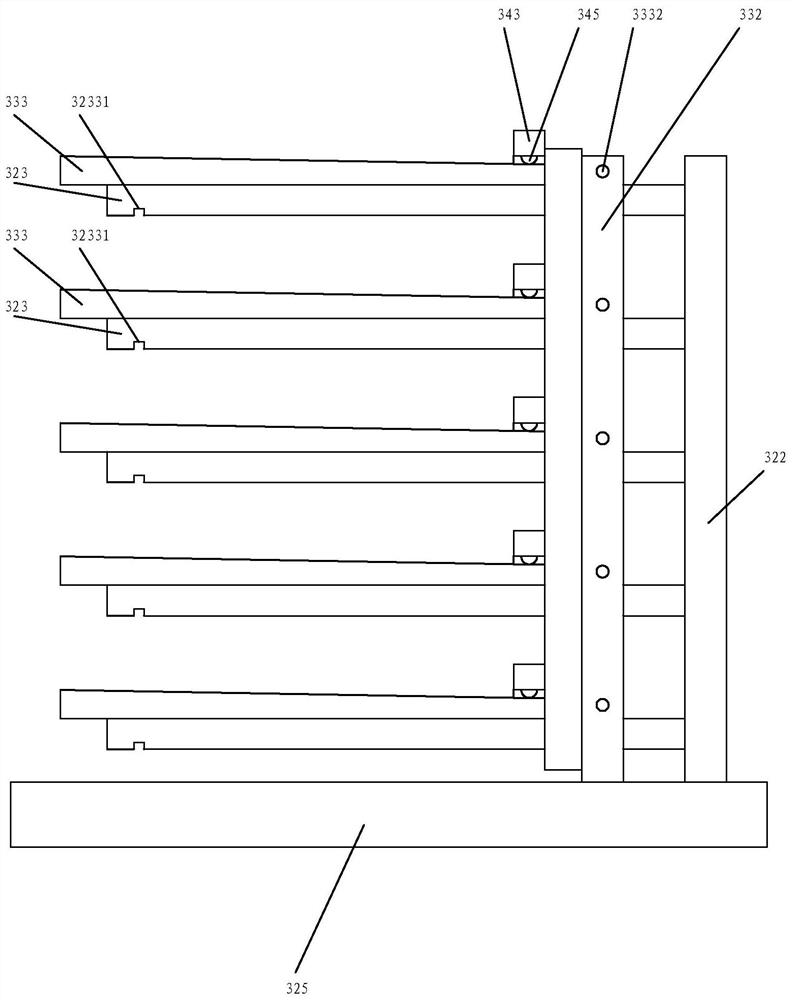

[0048] The transfer device 3 includes a movable base 31 , a movable bracket 32 arranged on the base 31 , a movable carrier 33 arranged on the movable bracket 32 to carry the multi-layer template blank 4 , and an abutment for abutting the template blank 4 . top part 34;

[0049] The moving bracket 32 includes a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com