A high barrier paper-plastic composite packaging film

A technology of paper-plastic composite and packaging film, which is applied in packaging, wrapping paper, transportation and packaging, etc. It can solve the problems of reduced barrier properties of paper-plastic composite packaging film, moisture permeability of paper-plastic composite packaging film, increase of oxygen permeability parameters, and Problems such as transient increase, to achieve the lowest production cost, stable barrier performance, and stable barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

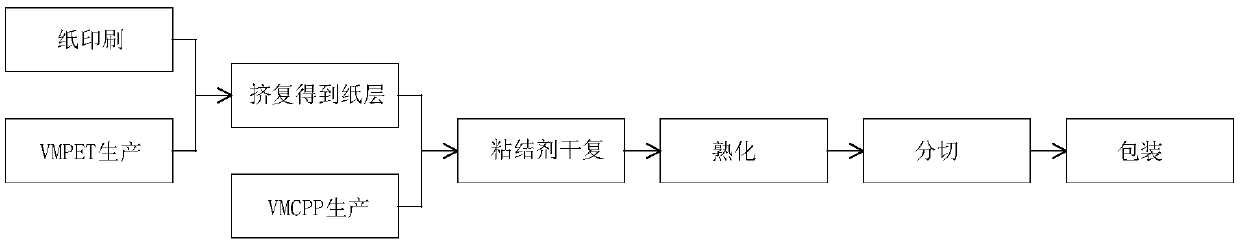

Method used

Image

Examples

Embodiment 1

[0029] The layer thickness ratio of the corona layer, the intermediate layer and the heat sealing layer is 3.2:20.5:6.3; the mass ratio of the terpolymer polypropylene material 1 and the ternary copolymer polypropylene material 2 is 0.9:1.1

Embodiment 2

[0031] The layer thickness ratio of the corona layer, the intermediate layer and the heat sealing layer is 2.8:21.5:5.7; the mass ratio of the terpolymer polypropylene material 1 and the terpolymer polypropylene material 2 is 1.1:0.9.

Embodiment 3

[0033] The layer thickness ratio of the corona layer, the intermediate layer and the heat-sealing layer is 3:21:6; the mass ratio of the terpolymer polypropylene material 1 and the ternary copolymer polypropylene material 2 is 1:1.

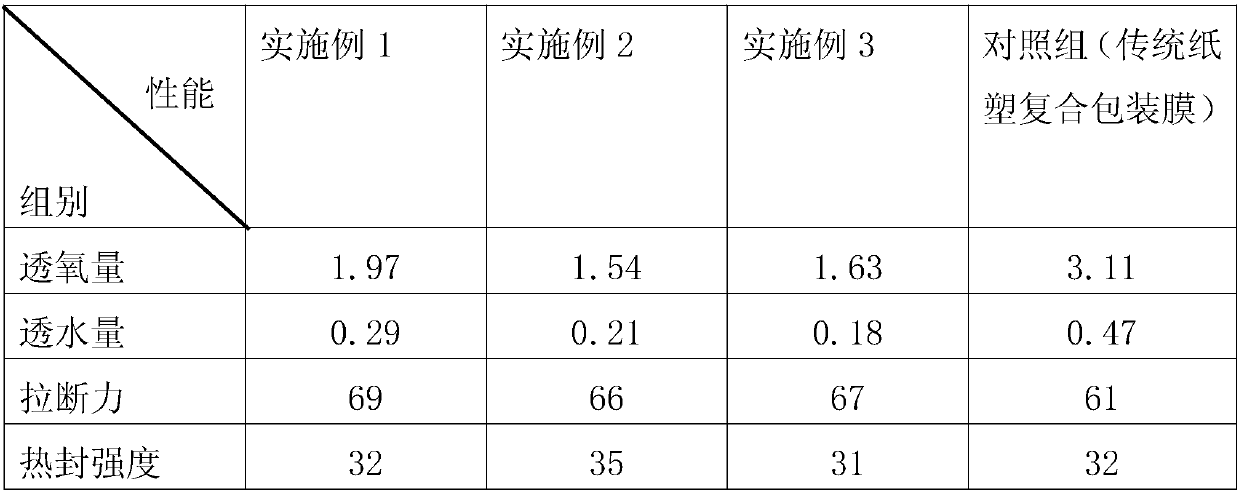

[0034] The following table 1 is the test comparison result of the performance of the obtained high-barrier paper-plastic composite packaging film of the present invention and the performance of the traditional paper-plastic composite packaging film:

[0035]

[0036] It can be seen from the results in the above table that the oxygen permeability and water permeability of the paper-plastic composite packaging film of the present invention are greatly reduced compared with the traditional paper-plastic composite packaging film, indicating that the barrier performance of the paper-plastic composite packaging film of the present invention is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com