Method for preparing ternary hydroxide from nickel, cobalt and manganese in waste lithium ion batteries recovered by liquid phase method

A lithium-ion battery and hydroxide technology, applied in the direction of nickel oxide/nickel hydroxide, battery recycling, recycling technology, etc., can solve the problems of difficult realization and inconvenient production, so as to improve utilization rate, save labor, and scale up convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

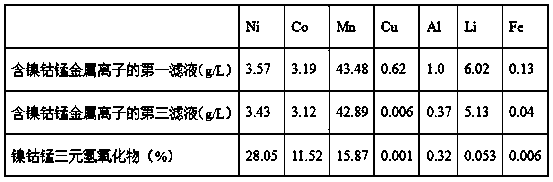

Embodiment 1

[0030] The method for preparing ternary hydroxide from nickel-cobalt-manganese in the waste lithium-ion battery recovered by the liquid phase method comprises the following steps:

[0031] (1) Dismantling and crushing: Soak the waste lithium-ion batteries in a 5% sodium chloride solution for discharge, disassembly, and direct crushing without sorting the positive and negative electrodes, and the size of the battery fragments is 5-30mm. After vibrating sieving, the large copper and aluminum flakes on the screen are recovered, and the under-sieve is the electrode active material powder;

[0032] (2) Slurry: add deionized water to the electrode active material powder obtained in step (1), control the liquid-solid ratio of slurry to 2:1, slurry temperature to 30°C, and slurry time to 0.1h , to obtain a slurry solution of the electrode active material;

[0033] (3) Leaching: Add concentrated sulfur to the electrode active material slurry solution obtained in step (2) according to ...

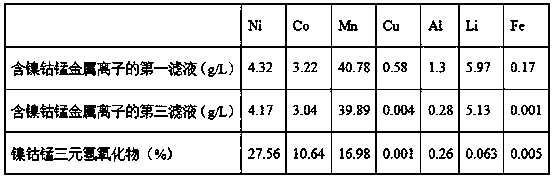

Embodiment 2

[0041] The method for preparing ternary hydroxide from nickel-cobalt-manganese in the waste lithium-ion battery recovered by the liquid phase method comprises the following steps:

[0042] (1) Dismantling and crushing: Soak waste lithium-ion batteries in a 5% sodium chloride solution for discharge, disassembly, and direct crushing without sorting the positive and negative electrodes to obtain battery fragments with a size of 5-30mm. After vibrating sieving, the large copper and aluminum flakes on the screen are recovered, and the under-sieve is the electrode active material powder;

[0043] (2) Slurry: Add deionized water to the electrode active material powder obtained in step (1), control the liquid-solid ratio of slurry to 3:1, slurry temperature to 40°C, and slurry time to 0.3h , to obtain a slurry solution of the electrode active material;

[0044] (3) Leaching: Add concentrated sulfur to the electrode active material slurry solution obtained in step (2) according to the...

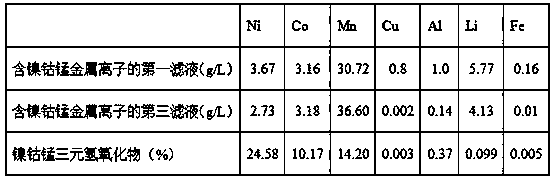

Embodiment 3

[0052] The method for preparing ternary hydroxide from nickel-cobalt-manganese in the waste lithium-ion battery recovered by the liquid phase method comprises the following steps:

[0053] (1) Dismantling and crushing: Soak waste lithium-ion batteries in a 5% sodium chloride solution for discharge, disassembly, and direct crushing without sorting the positive and negative electrodes to obtain battery fragments with a size of 5-30mm. After vibrating sieving, the large copper and aluminum flakes on the screen are recovered, and the under-sieve is the electrode active material powder;

[0054] (2) Slurry: Add deionized water to the electrode active material powder obtained in step (1), control the liquid-solid ratio of slurry to 4:1, slurry temperature to 60°C, and slurry time to 0.5h , to obtain a slurry solution of the electrode active material;

[0055] (3) Leaching: add concentrated sulfur to the electrode active material slurry solution obtained in step (2) according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com