Treatment system and method for zero-pollution discharge of livestock and poultry industry

A treatment system and breeding industry technology, which is applied in the direction of animal husbandry wastewater treatment, sludge treatment, water/sewage treatment, etc., can solve the problems of inconvenience, economy, cost of production area, etc., and achieve the goal of creating economic value and reducing washing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

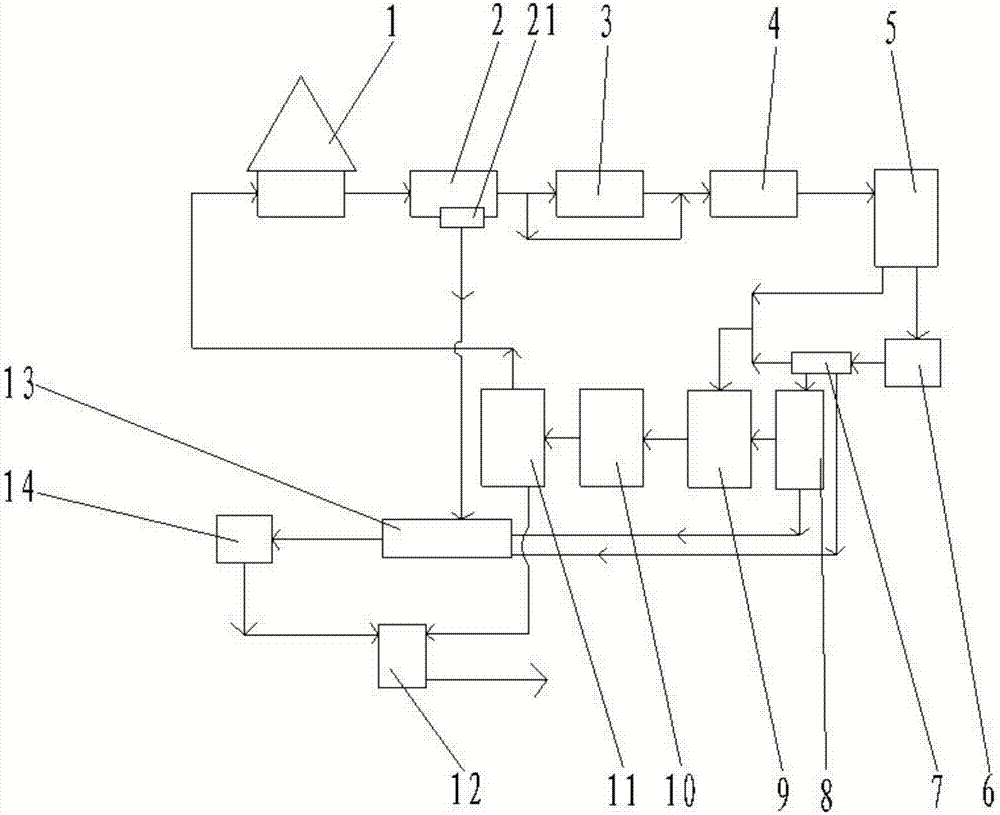

[0023] Such as figure 1 As shown, the present invention includes a livestock and poultry house 1, a collection pond 2, a biogas digester 3, a concentration and separation device 5, a blow-off device 9, a filter press device 7, a high-pressure steam boiler 8, a drying device 13 and a carbonization furnace arranged in sequence 12. The sewage outlet of the livestock and poultry house 1 is connected to the feed port of the collection pond 2 through a pipeline, and the discharge port of the collection pond 2 is connected to the feed port of the biogas digester 3. The feed liquid is transported from the discharge port of the biogas digester 3 to the feed port of the concentration and separation device 5 through pipelines and enters the concentration and separation device 5, and the liquid phase outlet of the concentration and separation device is connected to the feed port of the stripping device 9 , the solid phase outlet of the concentration separation device 5 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com