Washing device for gearbox gear shaft

A technology for cleaning device and gear shaft, which is applied in the direction of dry gas arrangement, cleaning method and utensils, cleaning method using liquid, etc., can solve the problems that the gear shaft cannot meet the needs of use, the cleaning effect is not ideal, and the cleaning efficiency is low. Achieve the effect of small footprint, ingenious design and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

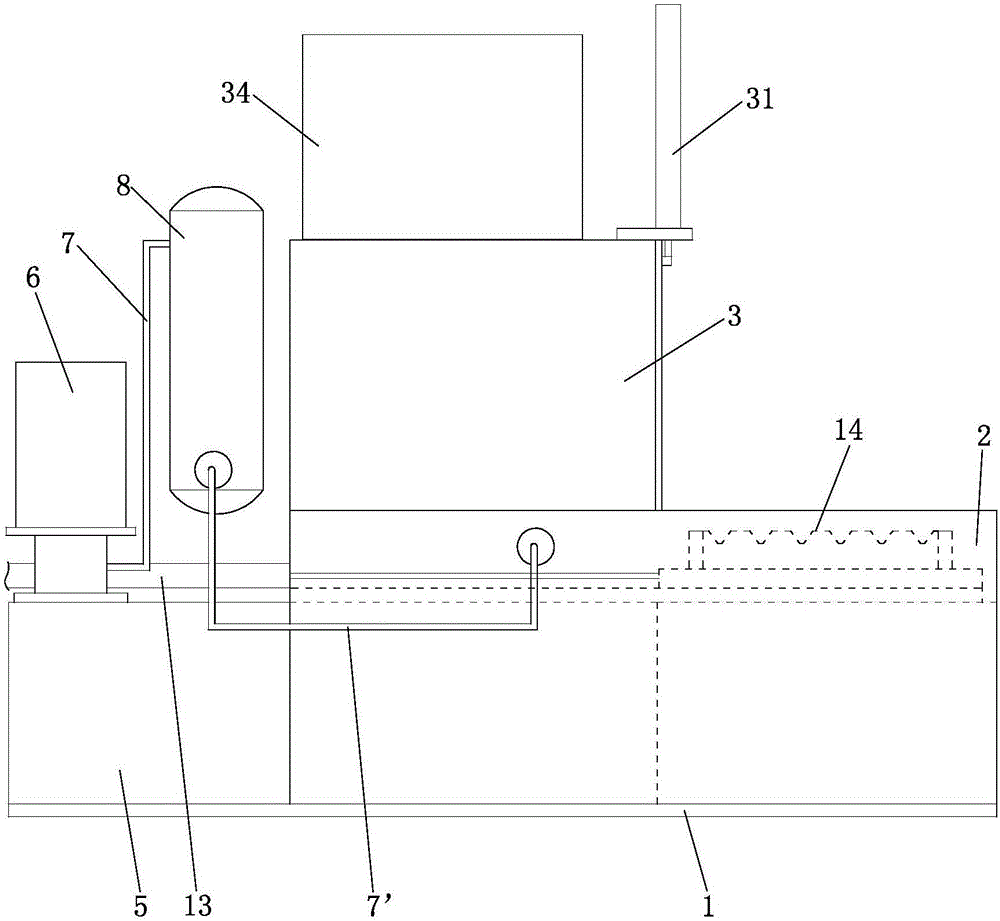

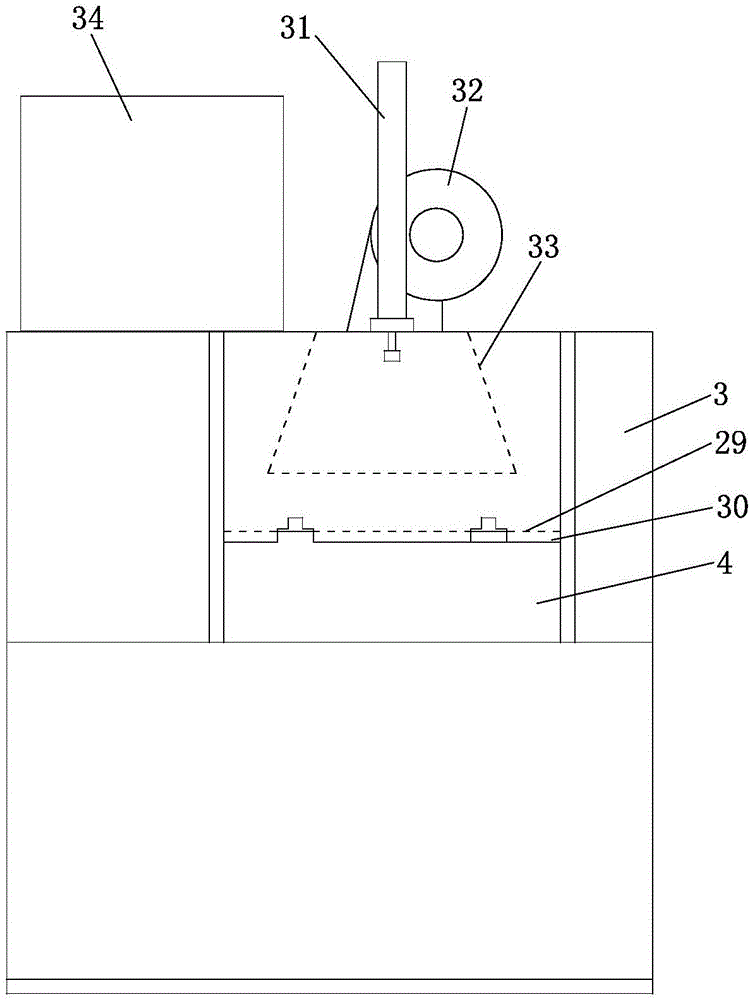

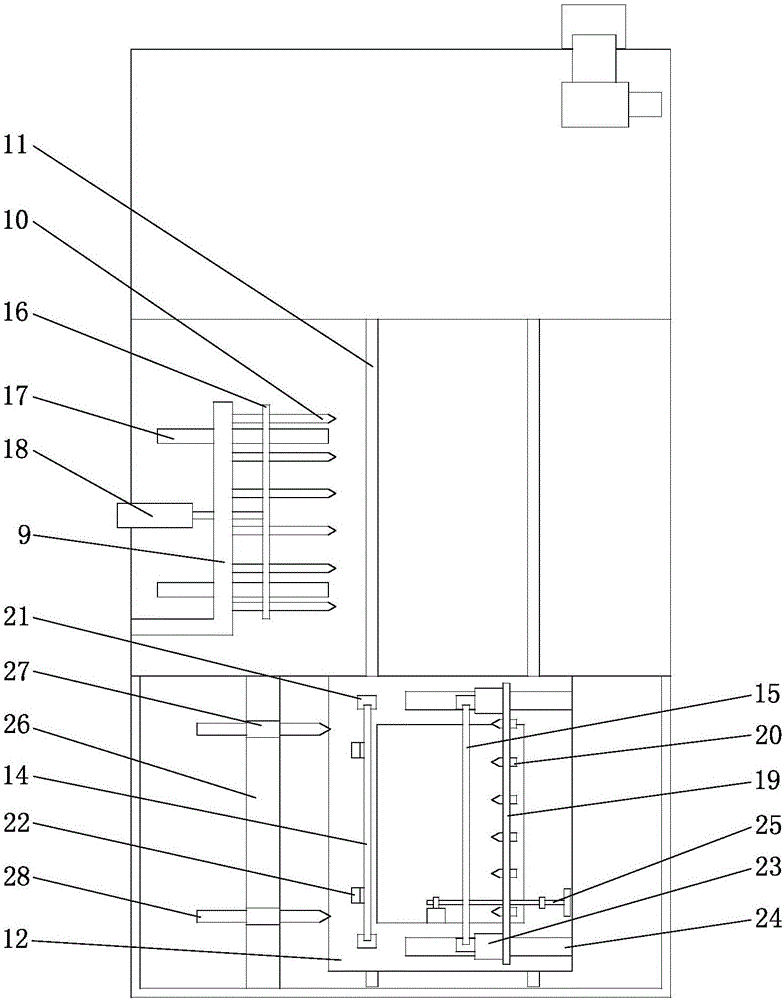

[0025] Such as figure 1 , figure 2 , image 3 As shown, an operation warehouse 2 is set on the top of the front end of the bed 1, and the upper end of the operation warehouse 2 is open. A cleaning chamber 3 is arranged above the middle part of the bed 1 , and a material inlet and outlet 4 is provided at the front end of the cleaning chamber 3 . The top of inlet and outlet opening 4 is covered by fixed door 29, and movable door 30 is provided with in the place ahead of fixed door 29, and the two ends of this movable door 30 are positioned at the guide chute of corresponding setting, the middle part of movable door 30 tops and vertical cylinder 31 The piston rod is connected, and the cylinder body of the vertical cylinder 31 is fixed on the top of the cleaning chamber 3 front ends. Under the action of the vertical cylinder 31, the dodge door 30 can be rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com