Drawer type cooling device

A cooling device and drawer-type technology, applied in the field of metallurgy, can solve problems such as difficult disassembly, unsafe online disassembly, and inconvenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

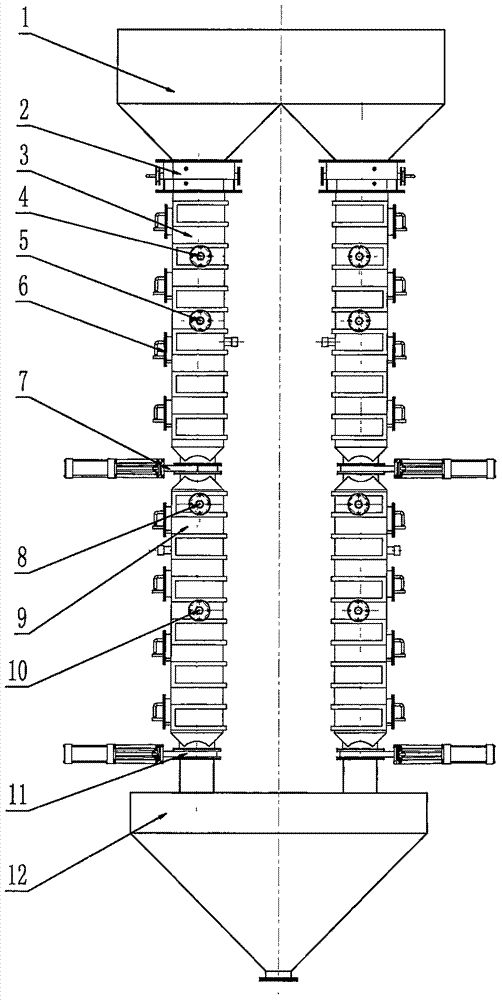

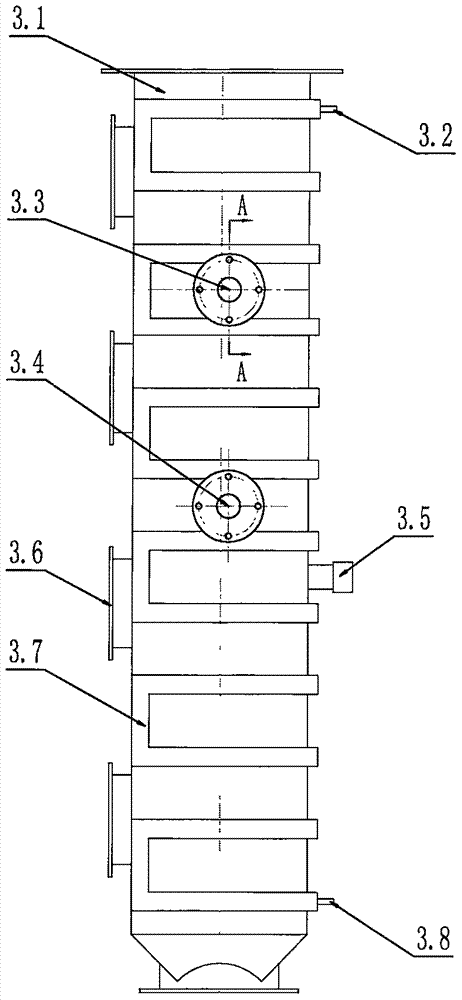

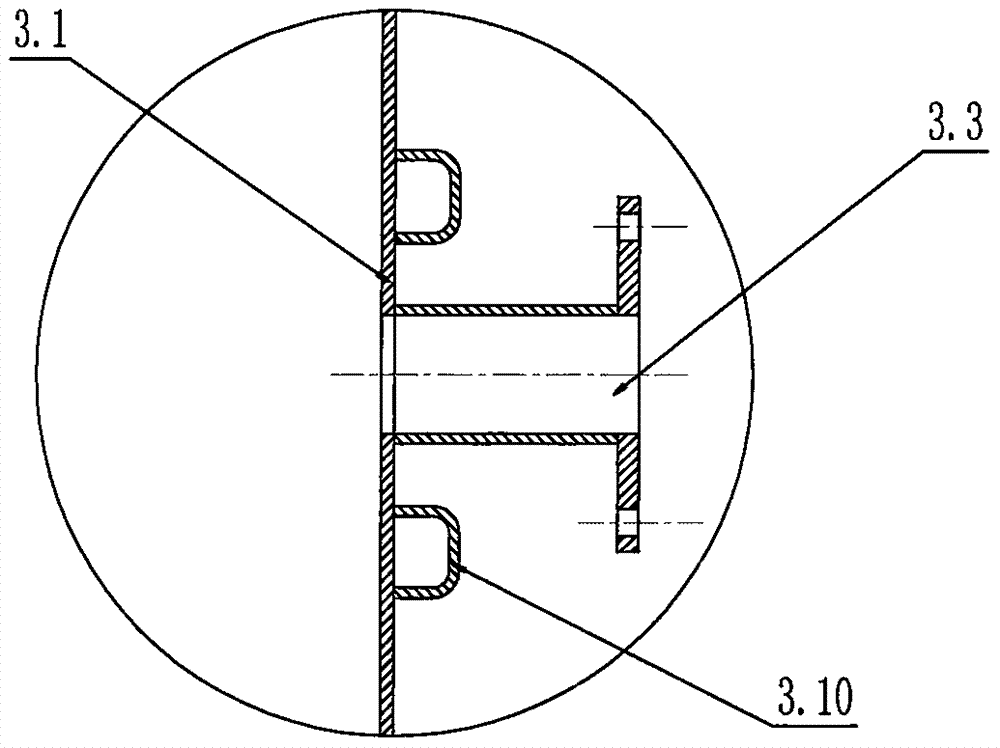

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 As shown, the drawer-type cooling device includes an ash bin 1 and an ash discharge hopper 12. The bottom of the ash bin 1 of the primary dust removal system is connected with the upper cooling chamber 3 through the upper shut-off valve 2, and the lower part of the upper cooling chamber 3 passes through the middle The cut-off valve 7 is connected with the lower cooling chamber 9, and the bottom of the lower cooling chamber 9 is connected with the ash discharge hopper 12 through the lower cut-off valve 11; the upper cut-off valve 2 is normally open during normal use, and the middle cut-off valve Both the valve 7 and the lower cut-off valve 11 are in the closed state. When the particles and dust in the upper cooling chamber 3 have accumulated a certain amount, the middle cut-off valve 7 is opened. At this time, the lower cut-off valve 11 is in the closed state, and the particles and dust are discharged to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com