A construction method of stonework static crushing

A technology of static crushing and construction method, which is applied in blasting and other directions, which can solve the problems of complex construction process, large amount of dust, and long construction period, and achieve the effects of shortening construction period, fast slag discharge and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with accompanying drawing and embodiment:

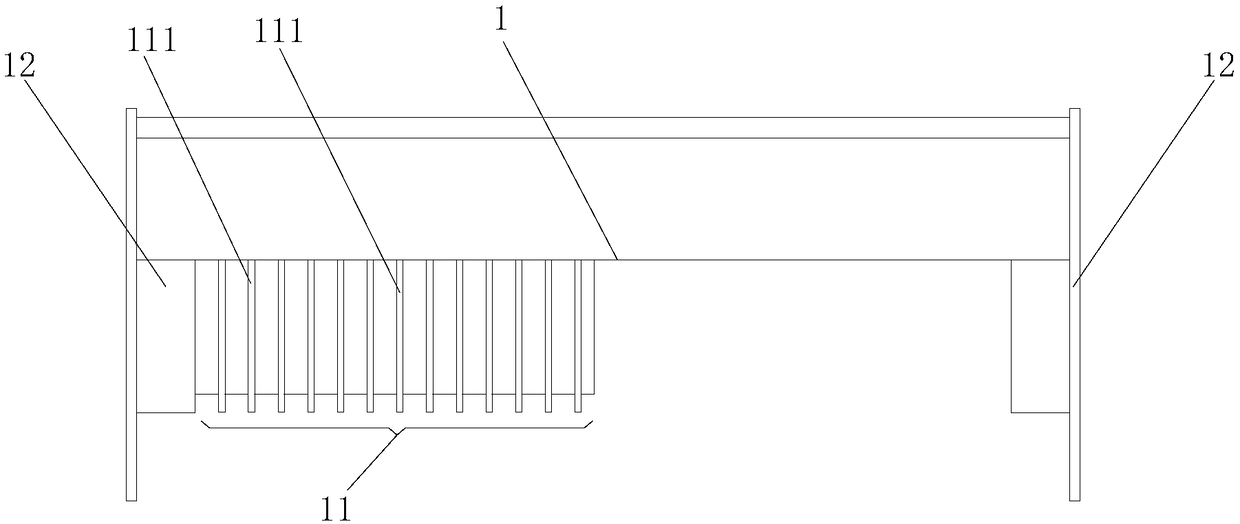

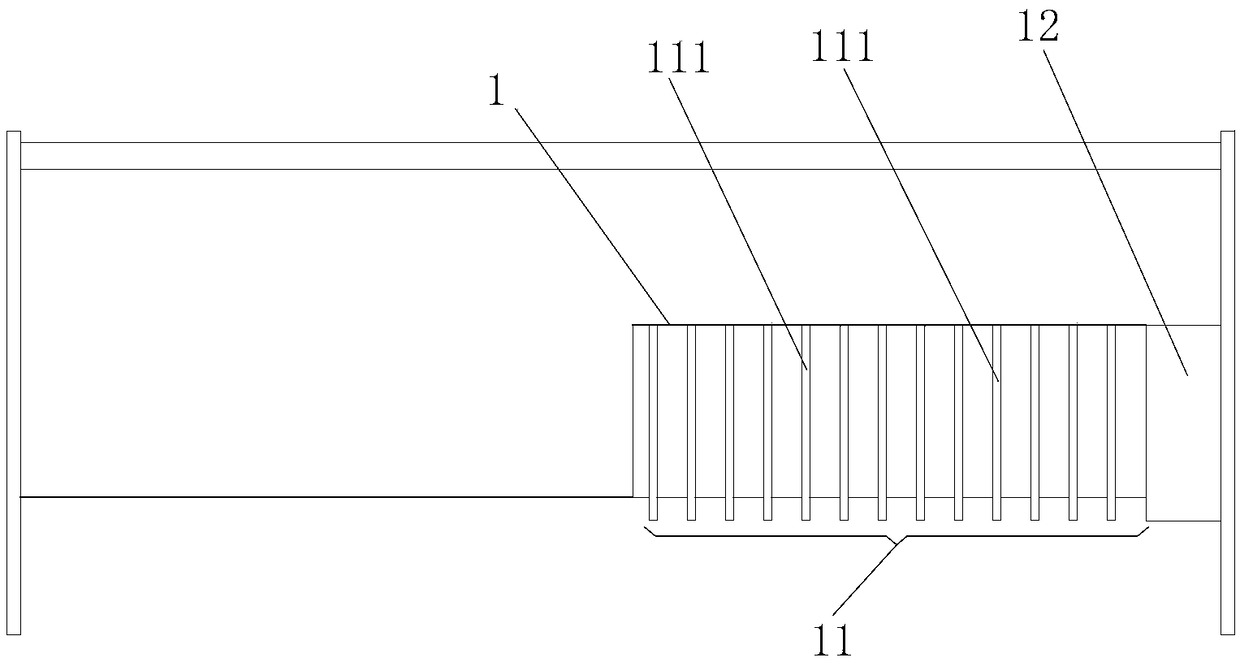

[0032] Such as Figure 1 to Figure 2 As shown, a construction method of stonework static crushing, including the following steps:

[0033] Step 1. Construction preparation: Excavation face 1;

[0034] Two or more working faces 1 are opened on the cross section of the foundation pit for gas explosion construction, and small gas explosion steps are formed during excavation to create lateral free surfaces. In this embodiment, two excavation working faces 1 are set up along the cross-section of the 23.1-meter-wide foundation pit, and gas explosion construction is carried out. The excavation forms a small step of gas explosion to create a lateral free surface. The working face steps are 3 meters high and about 11.5 meters wide. m.

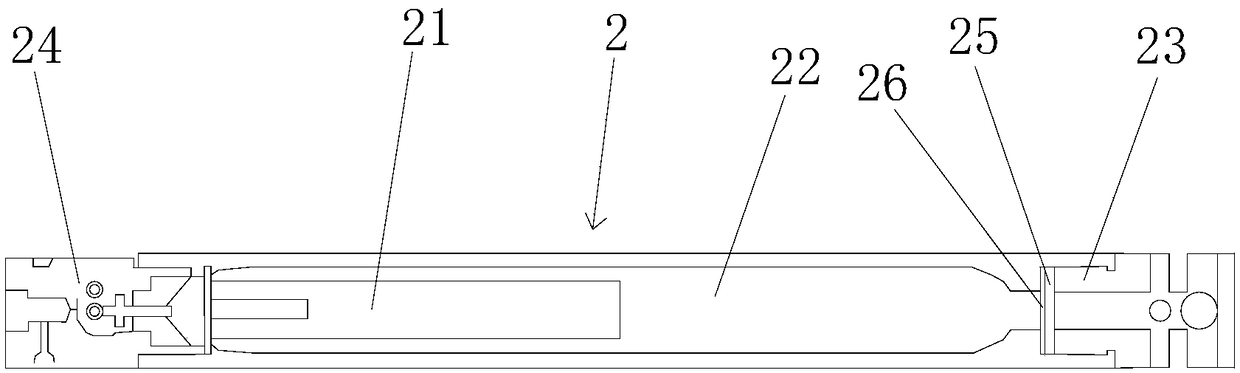

[0035] Step 2, drilling blastholes 111: drilling blastholes in the excavated working face 1, the blastholes 111 are vertical holes or o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com