A multifunctional rotating device for machine vision shooting

A machine vision, rotating device technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of large space occupation, high cost, complex calibration, etc., achieve high relative angular displacement accuracy, reduce the difficulty of shooting, Apply flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

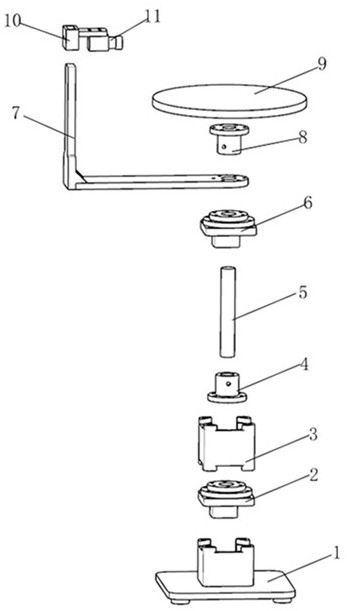

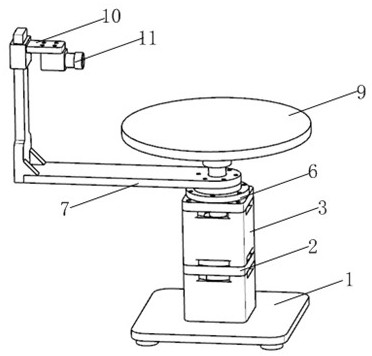

[0024] Embodiment 1: When multiple images are taken from a single viewpoint, the camera 11 is fixed and the object to be photographed is rotated; at this time, the motor II 6 does not work; the camera 11 is fixed on the camera support frame 7 through the camera holder 10, and the Lift and adjust the fixing screw, adjust the camera 11 to a suitable shooting height, and prepare to shoot; the motor I2 drives the carrying tray 9 to rotate through the motor coupling 4 and the tray coupling 8 on the rotating shaft 5, so as to realize the rotation of the object to be photographed, and the object to be photographed Every time a certain angle is rotated, the camera shoots once, and the object to be photographed rotates a circle of 360 degrees, and the camera takes multiple photos.

specific Embodiment approach 2

[0025] Embodiment 2: When multiple images are required to be taken from multiple viewpoints, the object to be photographed is fixed, and the camera 11 is rotated. At this time, the motor I2 does not work; the object to be photographed is placed on the carrier tray 9 and fixed, and the camera 11 is fixed by the camera. The frame 10 is fixed on the camera support frame 7, and the camera 11 is adjusted to a suitable shooting height by adjusting the lifting adjustment fixing screw, and the motor II 6 drives the camera 11 on the camera support frame 7 to rotate. Every time a certain angle is rotated, the camera shoots once, and the camera The support frame 7 rotates 360 degrees in one circle, and the camera takes a plurality of pictures.

specific Embodiment approach 3

[0026] Specific implementation mode three: when it is required to shorten the shooting time and improve the shooting efficiency, the camera and the object to be shot can be reversely rotated at the same time; at this time, the motor I2 and the motor II6 work at the same time; the motor I2 passes through the motor coupling 4 on the rotating shaft 5 and The tray coupling 8 drives the rotation of the object to be photographed on the carrying tray 9 to realize the rotation of the object to be photographed; at the same time, the camera 11 is fixed on the camera support frame 7 through the camera fixing frame 10, and the camera 11 is adjusted by adjusting the lifting adjustment fixing screw. To a suitable shooting height, the motor II 6 drives the camera 11 on the camera support frame 7 to rotate in reverse, and the object to be photographed and the camera 11 are rotated at a certain angle each time, and the camera shoots once, and the object to be photographed and the camera support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com