An experimental system and experimental method for micron-sized particles colliding with different surfaces

An experimental system and micron-level technology, applied in fluid dynamics tests, machine/structural component tests, instruments, etc., can solve problems such as luminous flux decline, atmospheric fine particle diseases, and output power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be further described below with reference to the accompanying drawings.

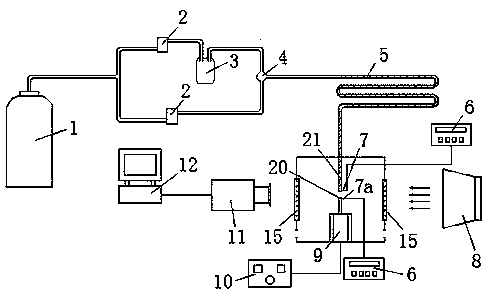

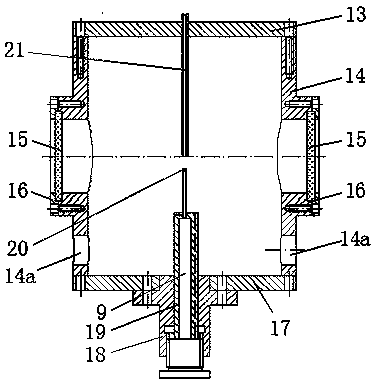

[0025] figure 1 , 2 It shows an experimental system diagram and a structural diagram of an experimental cabin in which micron-sized particles with controllable temperature and humidity collide with different surfaces.

[0026] In the figure, the experimental system for the temperature-humidity-controllable micron-sized particles colliding with different surfaces includes an experimental cabin, a light source 8, a high-speed camera 11, a computer 12, a micron-sized particle supply unit and an impactor set in the experimental cabin. unit. The experimental cabin includes an upper cover 13, an experimental cabin body 14 and a lower cover 17, and the experimental cabin body 14 is provided with two opposite quartz glass windows and openings 14a.

[0027] The micron-sized particle supply unit includes a carrier gas bottle 1, two mass flow meters 2, a wet parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com