Conical ratchet potato crushing separator

A technology for separators and potatoes, applied in grain processing, etc., can solve problems such as fragile bearings, difficulty in realization by ordinary technicians, and difficulty in small thorns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

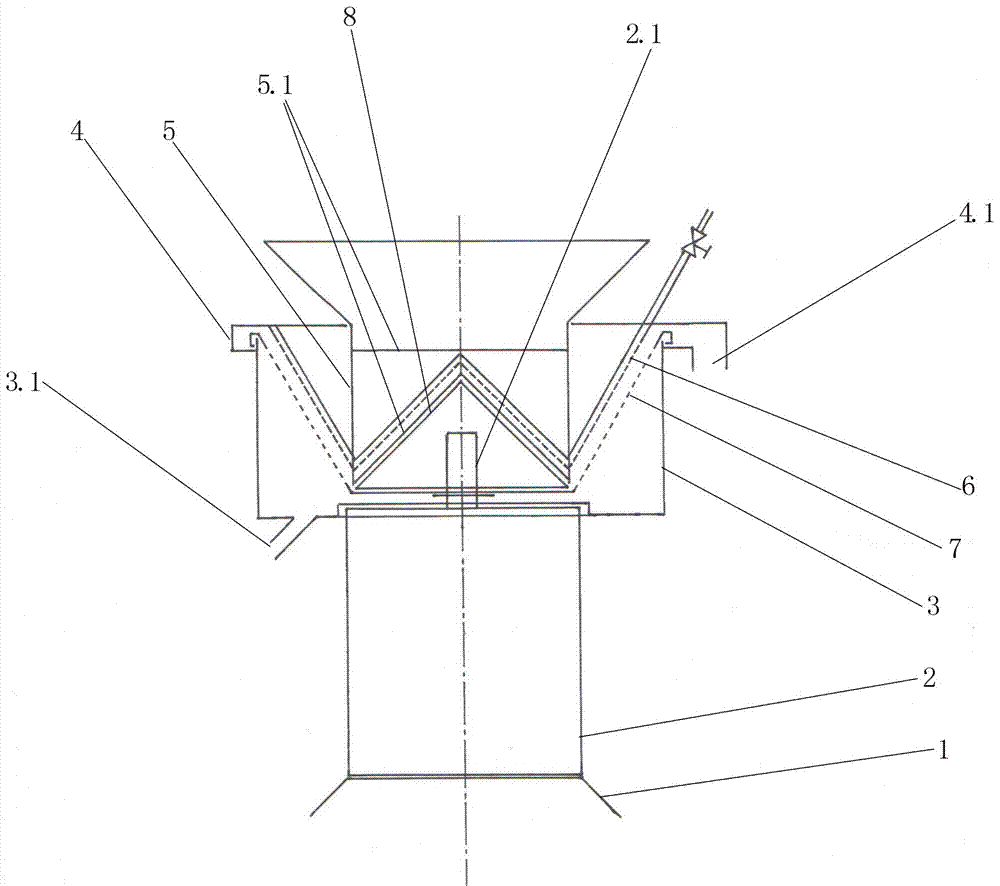

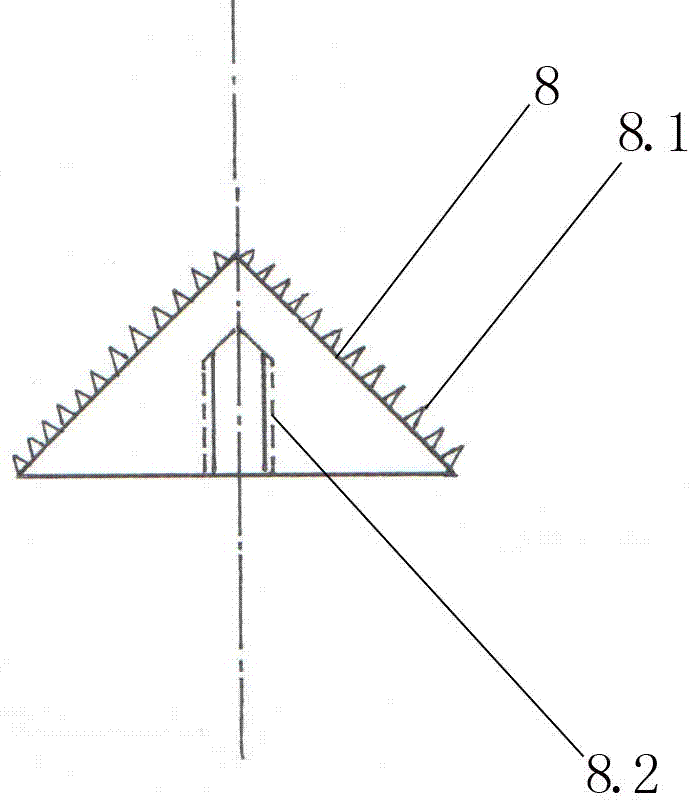

[0010] in figure 1 , 2 Among them, the cone-spindle type potato crushing separator provided by the present invention is an improvement of the existing ratchet type potato crushing separator. It consists of a base, a motor, a starch milk shell, a slag shell, a centrifugal screen, The cone-shaped ratchet wheel, hopper, and water spray pipe are characterized by: the lowermost part of the machine is the base (1), the base (1) has a vertical motor (2), and the upper end cover of the motor (2) has Retaining starch milk shell (3), the upper part of the retaining starch milk shell (3) is equipped with a slag retaining shell (4), the slag retaining shell (4) is equipped with a hopper (5), and the hopper (5) is equipped with a retaining plate (5.1), There is a "W"-shaped water spray pipe (6) under the hopper (5), a centrifugal screen (7) is fixed on the motor shaft (2.1), a cone-shaped ratchet wheel (8) is pressed on the centrifugal screen (7), and the centrifugal screen ( 7) The upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com