Method and apparatus for separating straw haulm

A technology of stem-leaf separation and straw, which is applied in the direction of agricultural machinery and tools, crop processors, cutters, etc., can solve the problems of leaf removal rate, straw moisture content and impact resistance, short service life of steel wire rope, and insufficient separation effect Ideal and other issues, to achieve the effect of convenient large-scale continuous operation, wide application range and low separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

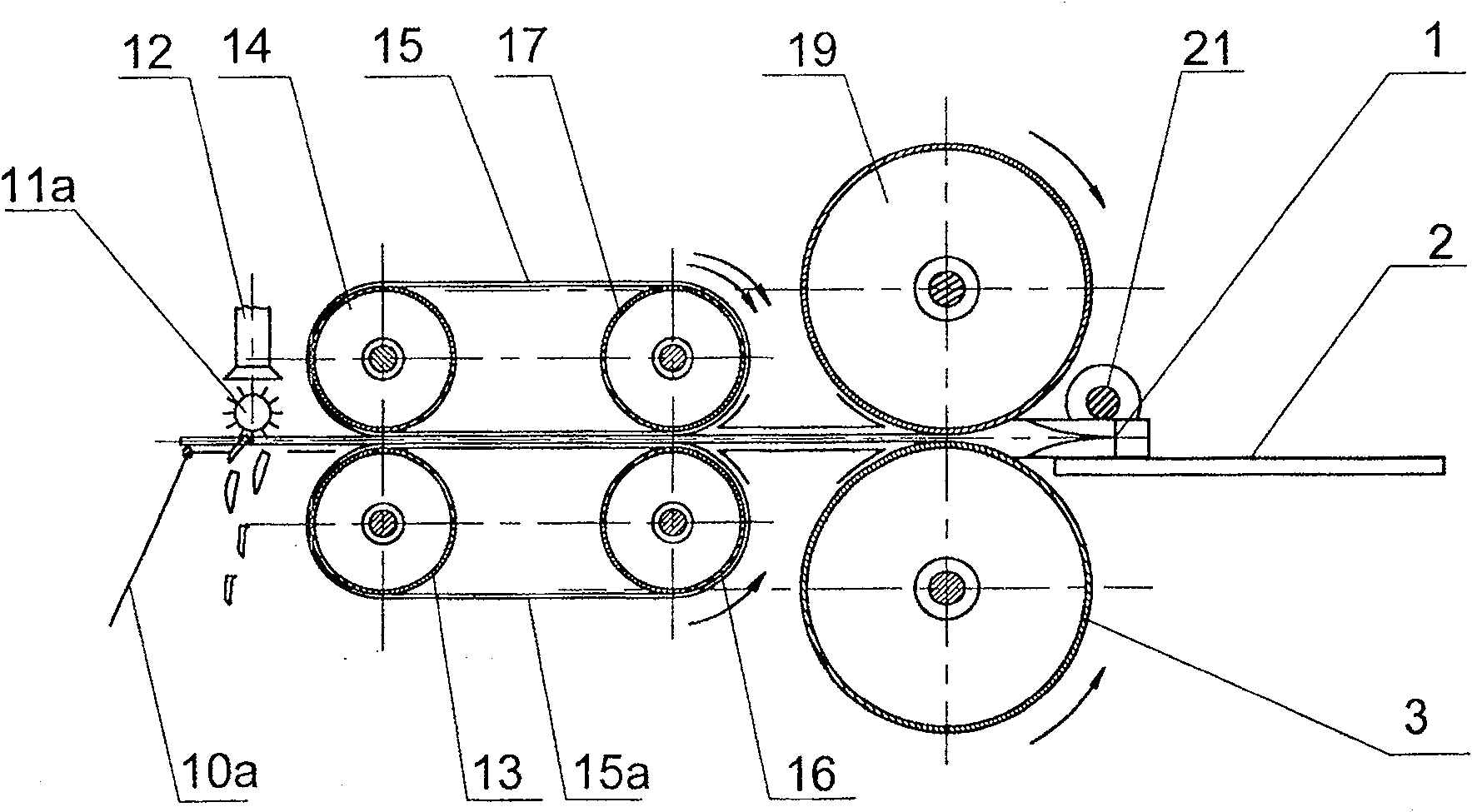

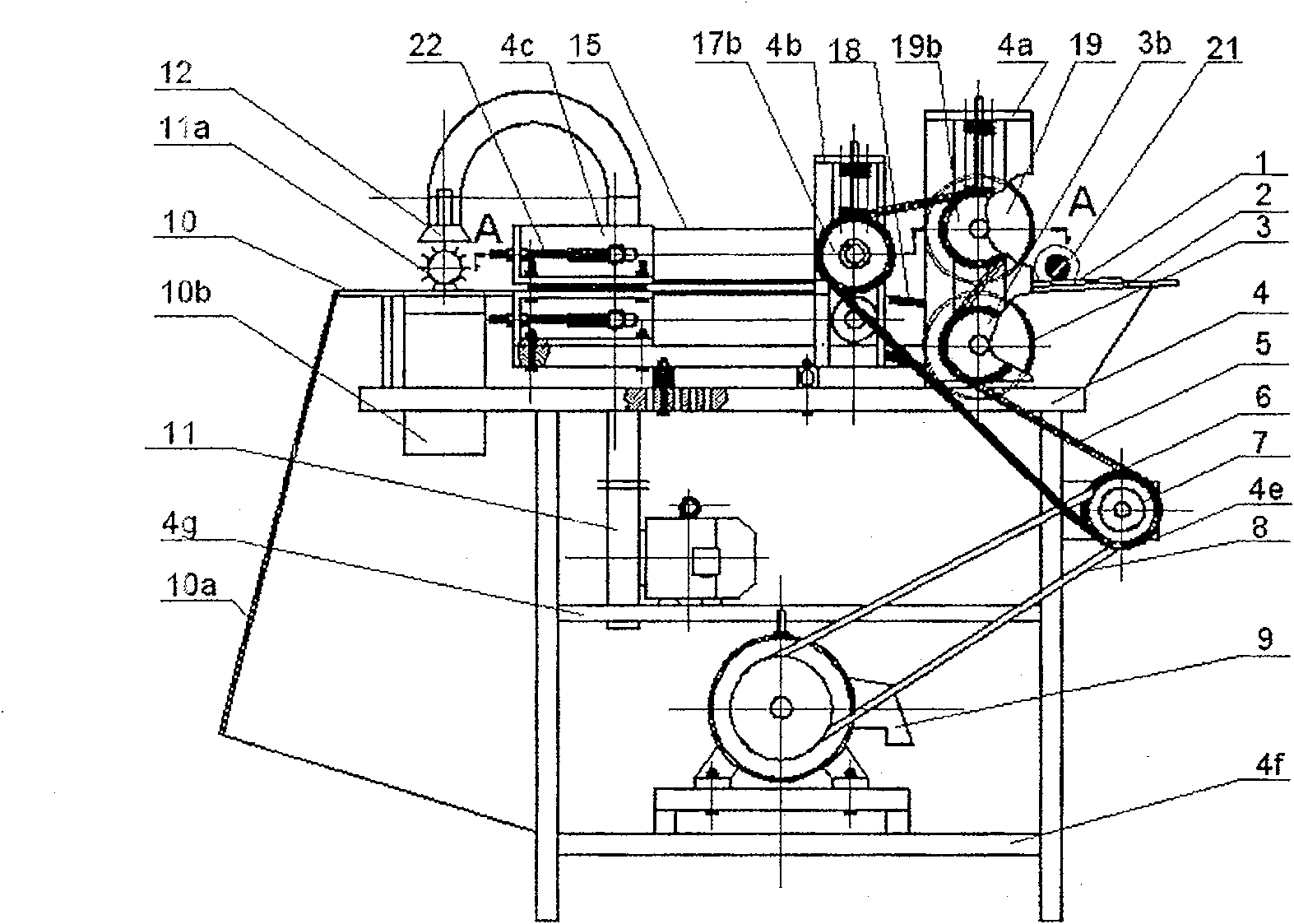

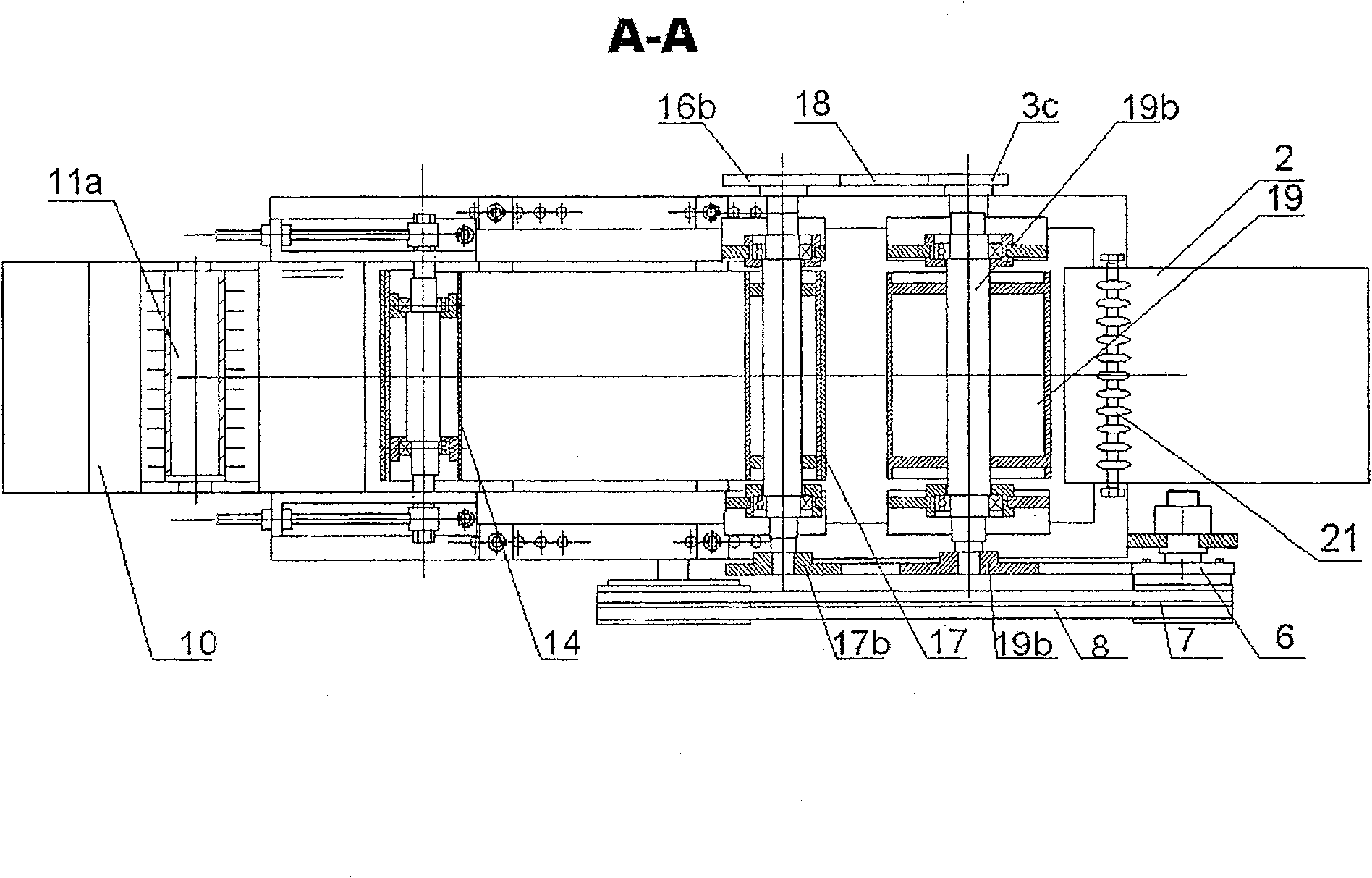

[0052] Embodiment 1 A kind of device for separating stem and leaf of straw

[0053] Further illustrate device of the present invention in conjunction with accompanying drawing, it comprises feed chute 2, lower pressure roller 3, frame 4, motor 9, discharge chute 10, blower fan 11, winnowing device 12, stripping leaf roller IV, stripping leaf Roller II, leaf stripping roller III, leaf stripping roller I, upper pressure roller 19, material management roller 21 are formed, described upper pressure roller 19 and lower pressure roller 3 are symmetrically installed on the loading plate 4a of frame 4 up and down, so Described leaf stripping roller IV and leaf stripping roller II, leaf stripping roller III and leaf stripping roller 1 are symmetrically installed on the leaf stripping roller support 4c and 4b of frame respectively, and leaf stripping roller II and leaf stripping roller I, leaf stripping Between the roller IV and the leaf stripping roller III, connect with the leaf strip...

Embodiment 2

[0062] Embodiment 2 A kind of method for separating stem and leaf of straw

[0063] 1. The process route of flattening and rolling method is:

[0064] Raw materials of straw→removing tips→single-layer flattening→grinding→cleaning→separation of stems and leaves

[0065] 2. Material selection

[0066] The raw material of straw is corn straw produced in Yangling area, Shaanxi Province, with an average plant height of 215cm, an average root circle diameter of 2.7cm, a moisture content of 19.5%, and an average leaf content of 42.7%.

[0067] 3. Specific operation steps

[0068] ①Remove the tips: Use a hay cutter to cut off the tips of 10-80cm in batches. In this embodiment, 30 cm of tip is removed.

[0069] ②Single-layer flattening: Manually spread 1~several straws 1 after the tip removal in parallel in the feeding trough 2 along the feeding direction, with the root of the straw facing forward, and gently push it to touch the material roller 21. Under the action of the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com