Intelligent bottle scrubbing machine

A technology for scrubbing machines and bottles, applied to cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of poor cleaning effect and high labor intensity, achieve good cleaning effect, improve cleaning effect, and simplify cleaning The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

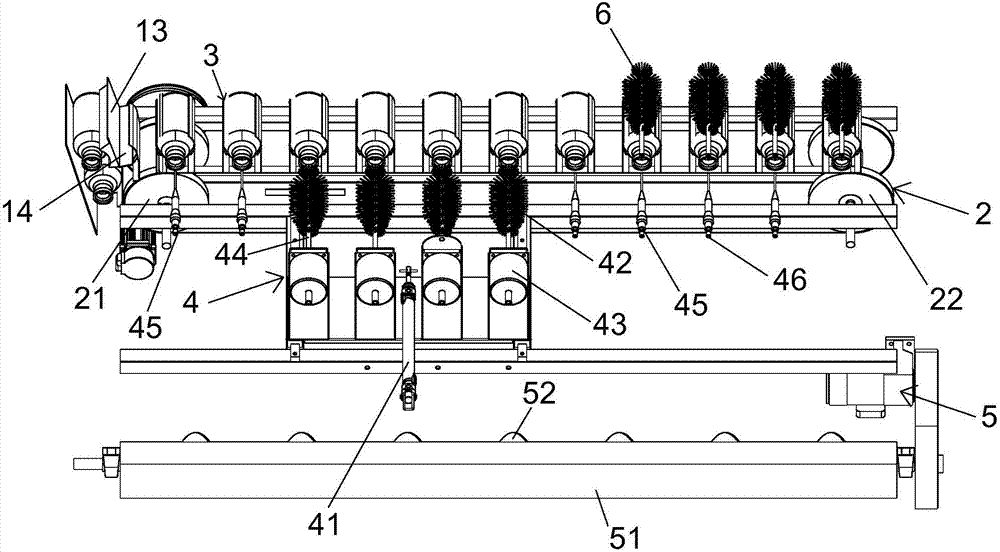

[0039] The upper side of the feed port 11 is provided with a clamping plate 13, which forms a limiting channel with the bottom plate of the feed port 11; the upper end of the clamping plate 13 is hinged on the frame 1, and the clamping plate 13 is provided with Only the toggle piece 14 that is limit-cooperating with the upper end of the right clamping plate 32; The right clamping plate 32 is higher than the left clamping plate 31 .

[0040] When the pressing plate 13 is in the natural state, it presses the bottle at the outlet position of the feeding port 11 to prevent it from falling into the conveying mechanism 2; The material plate 13 is turned upwards, and the bottle at the outlet position of the feeding port 11 naturally falls between the left clamping plate 31 and the right clamping plate 32 . see Figure 9-10 .

Embodiment 2

[0042] In two adjacent clamping assemblies, an elastic piece 35 is connected between the right clamping plate 32 of the left clamping assembly and the left clamping plate 31 of the right clamping assembly, and the elastic piece 35 forms a slope, and the right side of the slope is higher than the left side , the bottle that falls on the slope can be rolled into the left clamping assembly. see Figure 11 .

Embodiment 3

[0044] A gate driven by a power part is set at the outlet of the feeding port 11 , and a trigger switch that cooperates with the clamping assembly near the feeding port 11 and controls the power part is provided on the frame 1 . When the left splint 31 or the right splint 32 moves to the trigger switch position, the power part controls the gate to open automatically.

[0045] The cleaning assembly includes more than one set of brushes 42 arranged at intervals along the conveying direction and a rotating motor 43 that drives the brushes 42 to rotate. The brush 42 is a threaded brush.

[0046] The cleaning assembly also includes a spray pipe 44 for spraying water into the bottle, and the spray pipe 44 is arranged on the rotating shaft of the brush 42 .

[0047] The driving assembly 41 is an air cylinder, and the cleaning assembly is arranged on the sliding plate, and the displacement is driven by the air cylinder, and the telescopic angle of the air cylinder is the same as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com