A kind of production method of highly wear-resistant tbm roadheader blade

A production method and technology of roadheader, applied in the direction of casting molding equipment, casting mold components, manufacturing tools, etc., can solve the problems of complex production process, high cost, low precision, etc., to improve utilization rate, improve hardness and wear resistance , Improve the effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0028] A kind of production method of high wear-resisting TBM roadheader blade of the present invention specifically comprises the following steps:

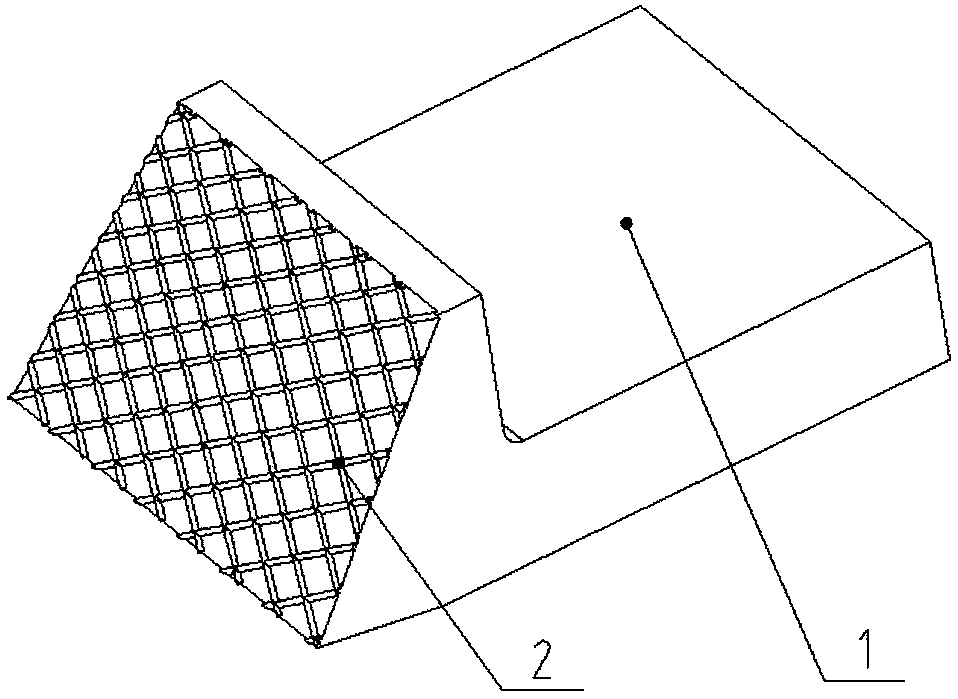

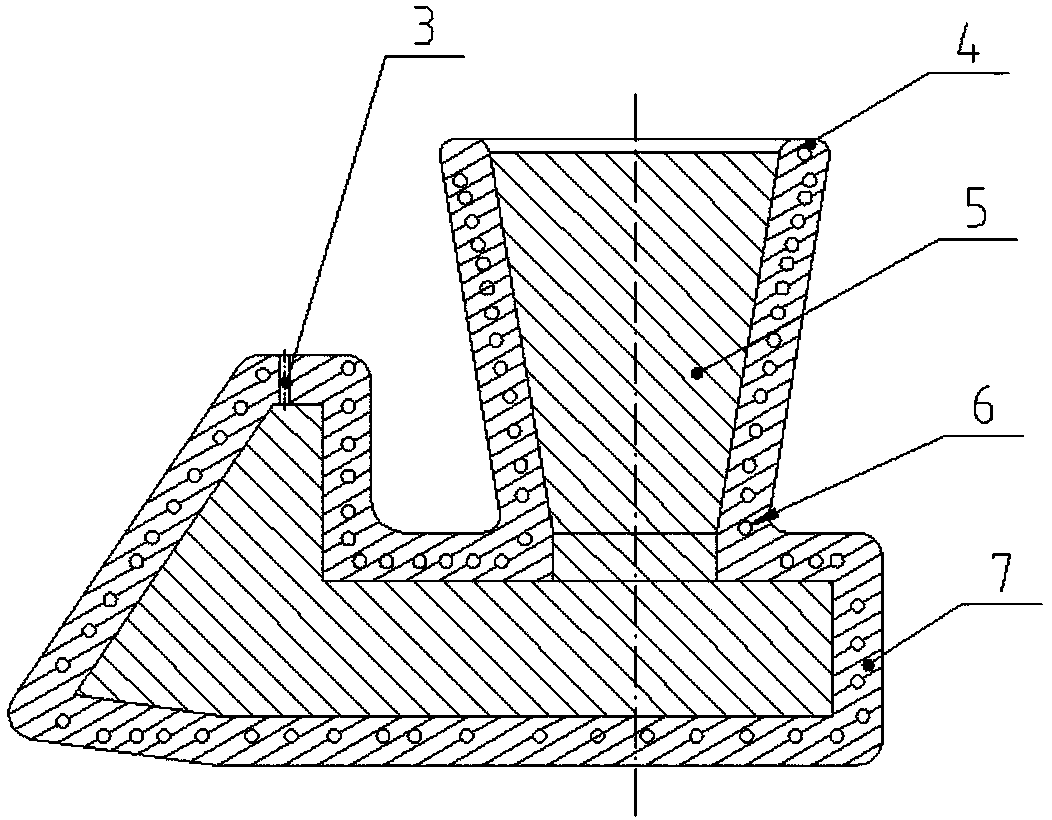

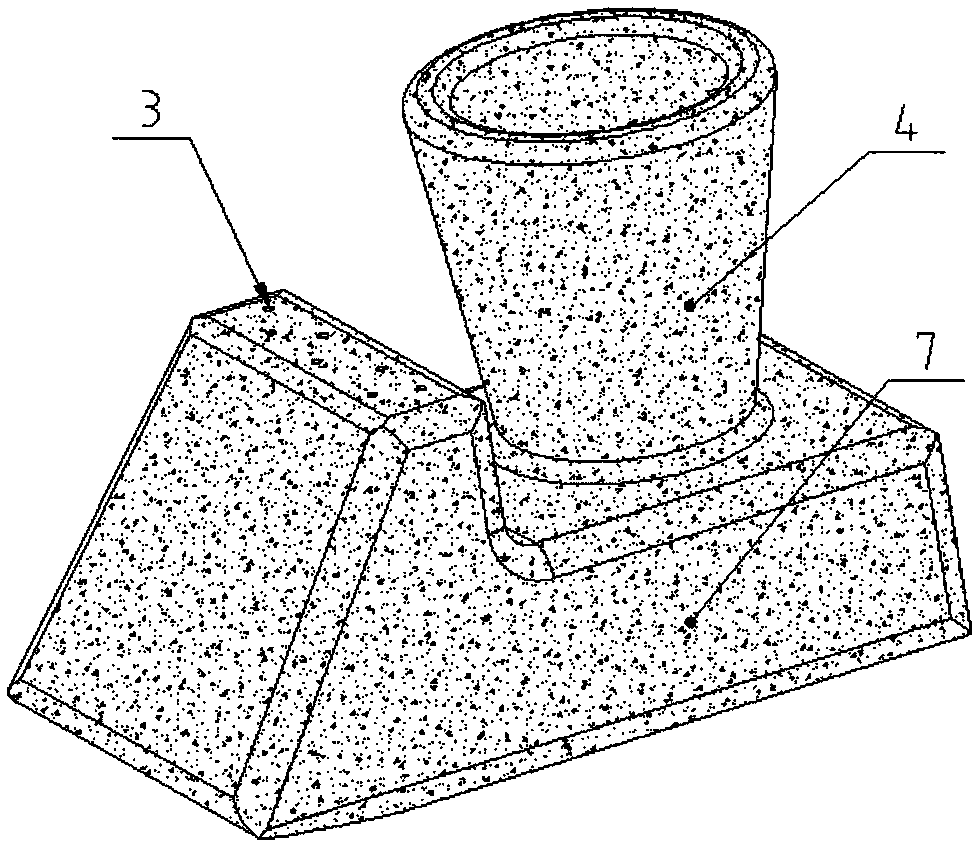

[0029] Step 1: Make a foam model of the spatula; according to the size requirements of the spatula, use foam to make the foam model 5 and the pouring riser 4 of the spatula;

[0030] Step 2: Prepare quartz powder slurry; add water to dilute water glass with a modulus of 2.8-3.0 to a density of 1.24-1.26g / cm 3 , then add 320 mesh quartz powder, the weight ratio is 1:1.3-1.4, use a mixer to carry out mechanical stirring, after stirring evenly, add 0.05wt% cleaning agent and 0.05wt% defoamer, continue stirring, stirring time 7 hours, static Place it for 5 hours to ripen, and then stir again before use after ripening;

[0031] Step 3: Prepare high alumina powder slurry: Dilute water glass with a modulus of 2.8-3.0 to a den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com