A straight-axis brake device with power-off self-locking function

A brake device and functional technology, applied in the field of direct-axis brake devices, can solve the problems of machining accuracy and equipment safety, hidden safety hazards of five-axis machine tools, and the inability to provide reliable brake functions, etc., to improve processing precision and safety , good practical value, and the effect of improving location flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described in conjunction with the following examples.

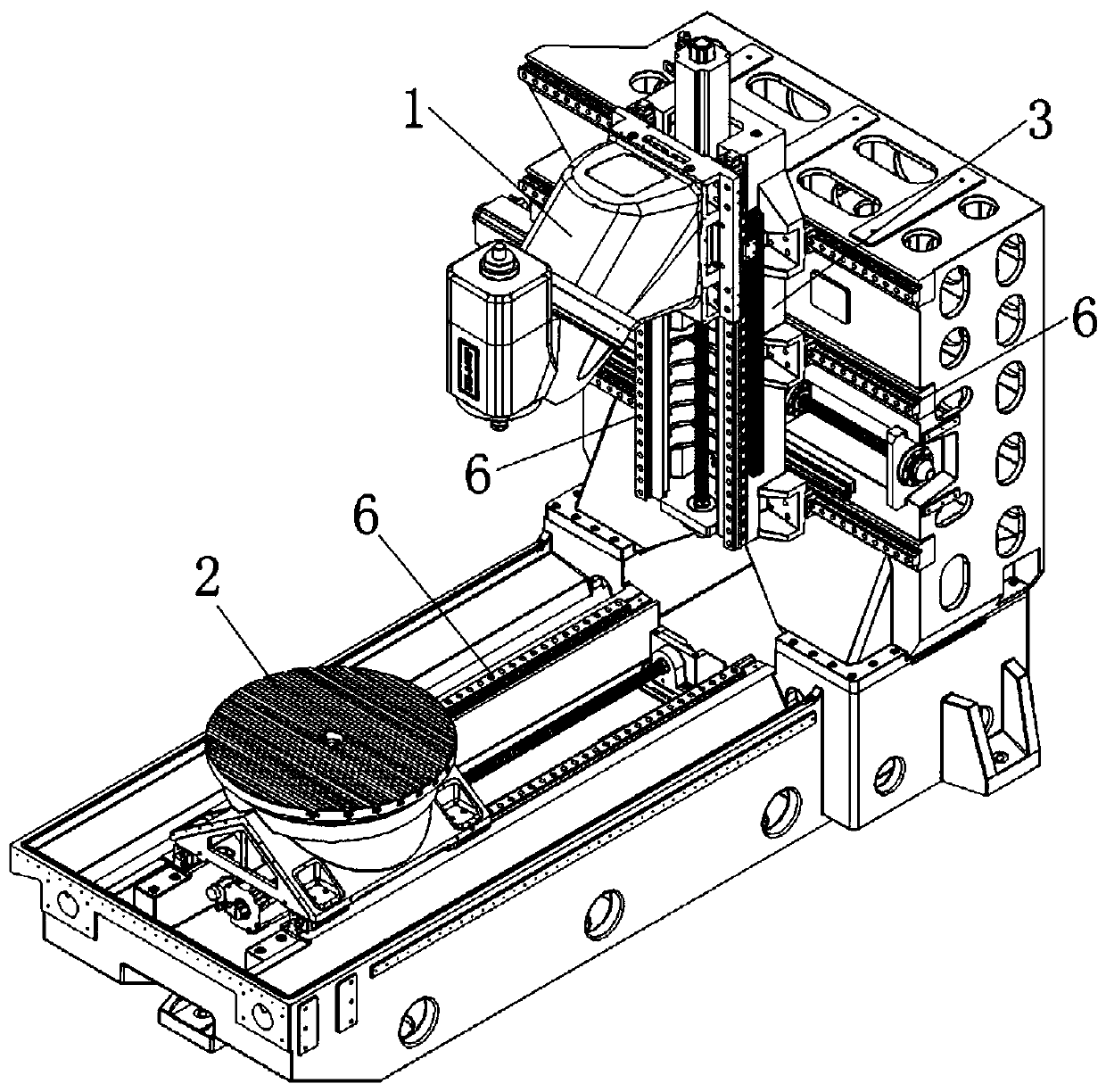

[0015] See figure 1 , is the overall schematic diagram of the five-axis machine tool. The brake device is used to stop the working mechanism of the machine tool. The working mechanism of the machine tool can be the swing head body 1 on the Z axis, the rotary table 2 on the Y axis, and the saddle on the X axis. 3, etc., can also be used for any machine tool working mechanism on the straight axis track.

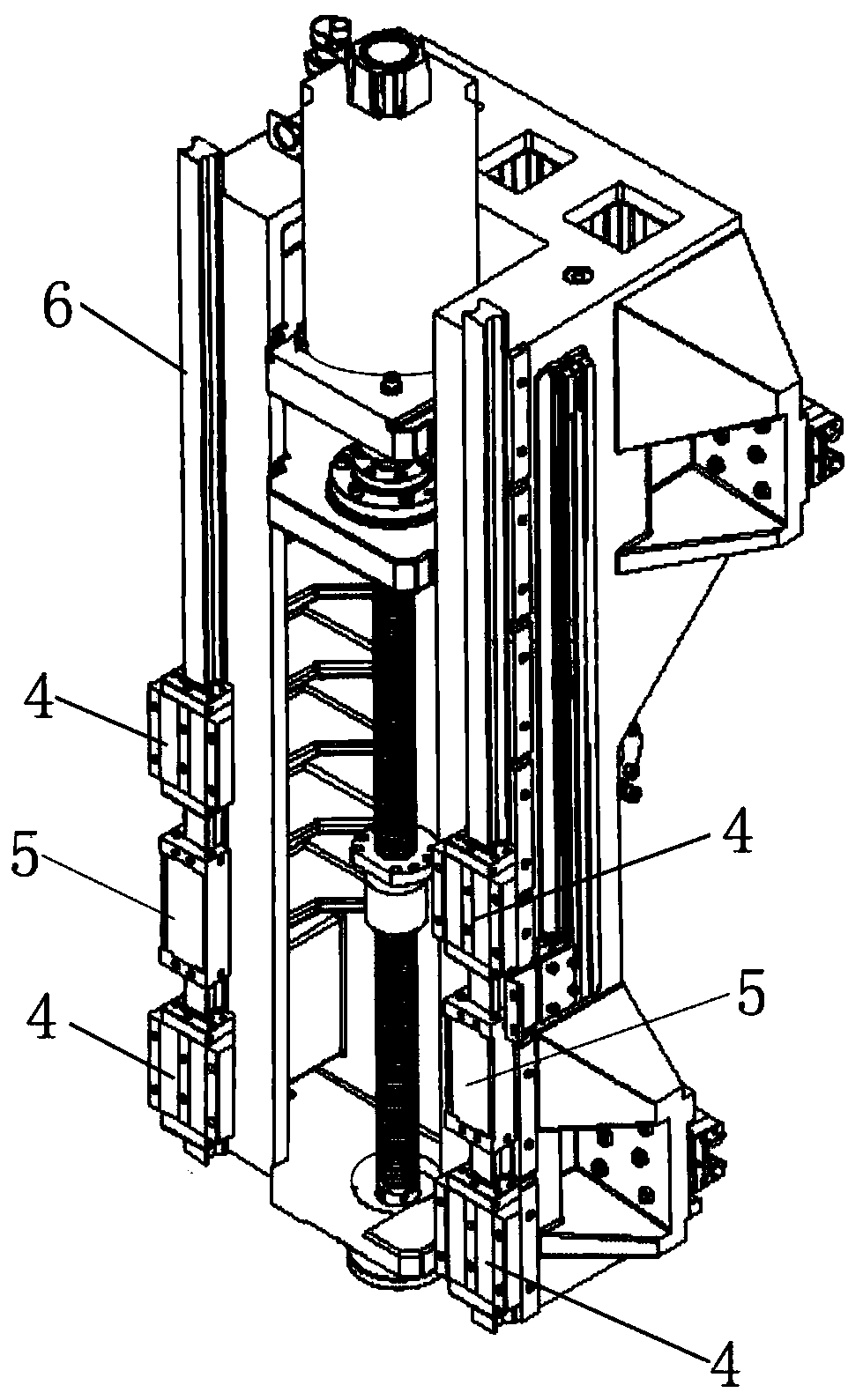

[0016] See figure 2 , taking the Z axis as an example, it is a schematic diagram of the position of the brake device on the track, the swing head body 1 (for the sake of clarity, figure 2 Not shown in the swing head body 1) is respectively connected with four slide blocks 4 and two braking devices 5 by bolts, and the sliding blocks 4 and the braking devices 5 can slide on the track 6.

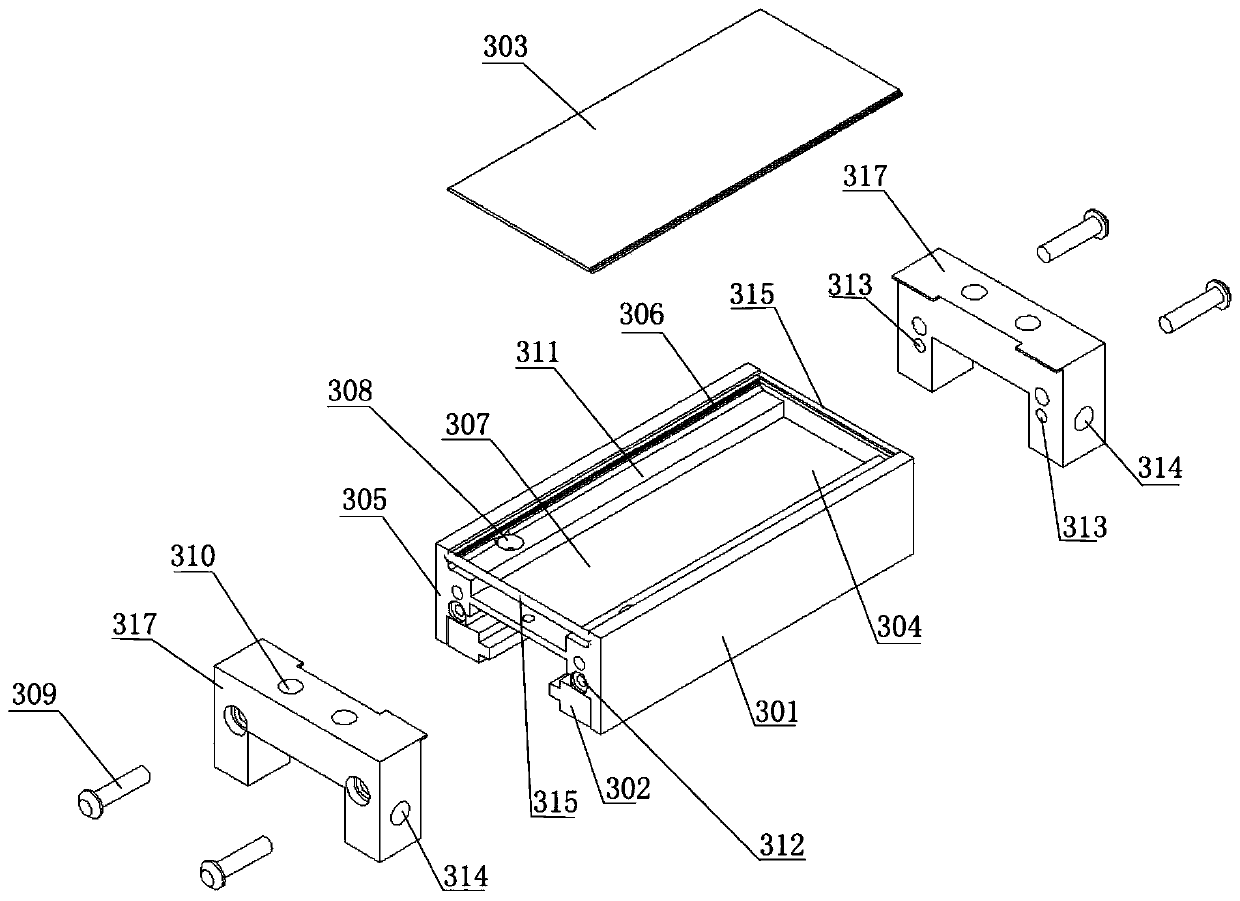

[0017] See eg Figure 3-5 , the brake device 5 includes a brake housing 301, a brake wear pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com