Vehicle roof positioning and machining auxiliary tool and vehicle roof integrated machining method based on same

A technology of positioning assistance and auxiliary tooling, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as not being able to meet the requirements of CNC programming and processing, lack of positioning function, and deviation of positioning effect data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

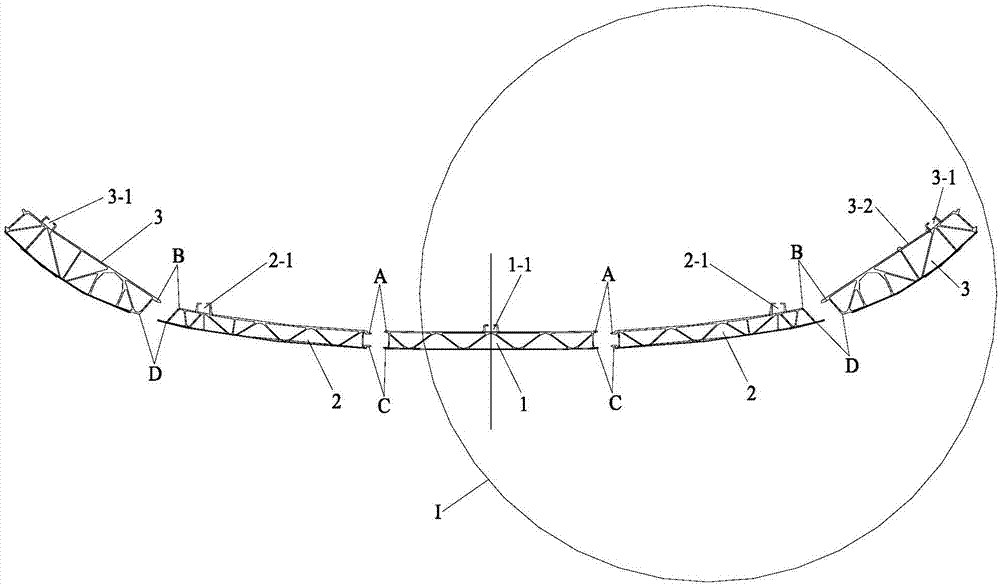

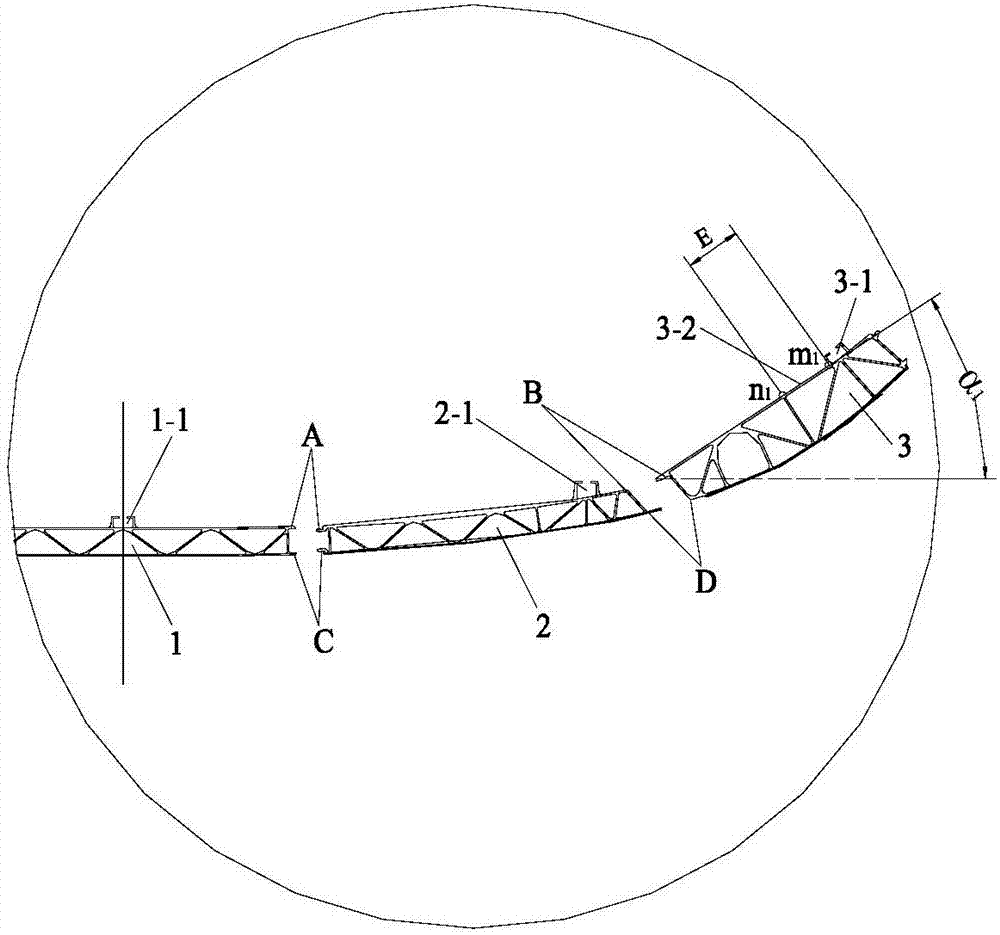

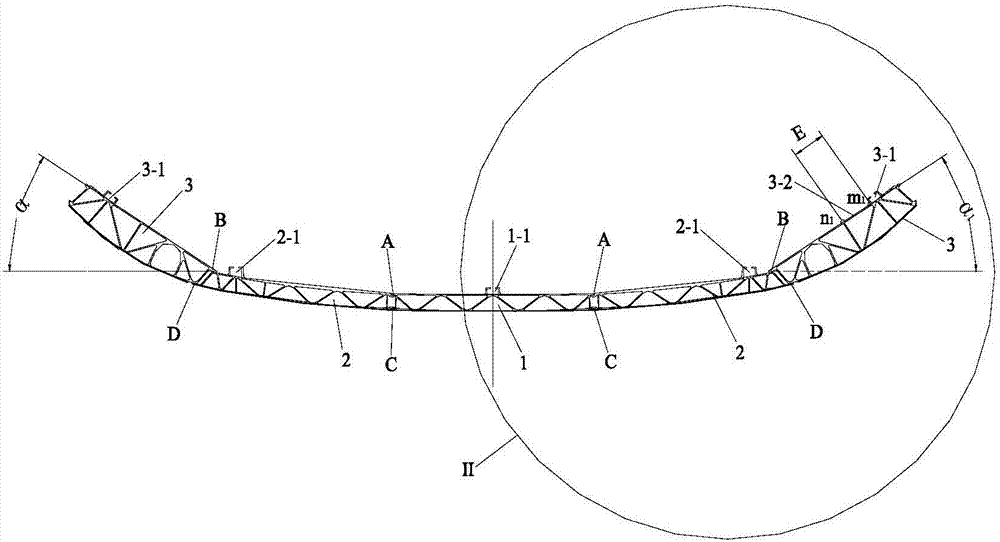

[0082] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0083] The roof processing and positioning auxiliary tooling of the present invention includes a central circular arc plate slot positioning mechanism 10 and a roof blind hole positive fast positioning mechanism 11, such as Figure 19 or Figure 27As shown, the central arc plate slot positioning mechanism 10 includes a base 10-1, a vertical height guide rail 10-2, a vertical slider 10-3, a height adjustment cylinder 10-4, a hinge seat 10-5 and a slot The positioning platen 10-6, the lower end of the vertical height guide rail 10-2 and the height adjustment cylinder 10-4 are vertically fixed on the base 10-1, and the axial and vertical height guide rails 10-2 of the height adjustment cylinder 10-4 In parallel, the vertical slider 10-3 is slidably connected with the vertical height guide rail 10-2. Hinge shaft seat 10-5 comprises hinge shaft base plate 10-5-1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap