Engine oil filter element rotation machining table

A technology of rotary table and oil filter, which is applied in the direction of presses, manufacturing tools, material forming presses, etc., can solve problems affecting processing efficiency, etc., and achieve the effects of improving production efficiency, reducing finished product costs, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

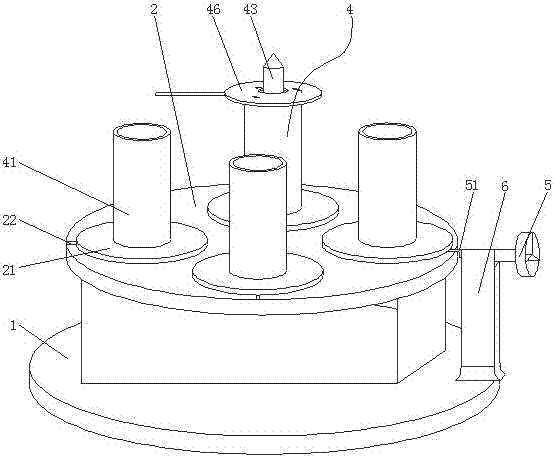

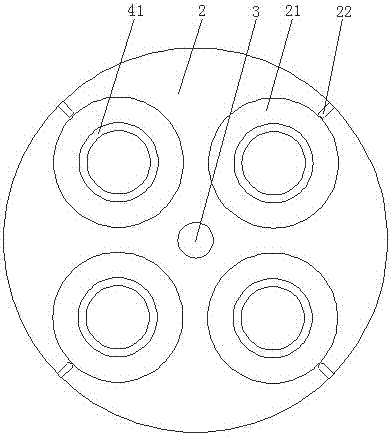

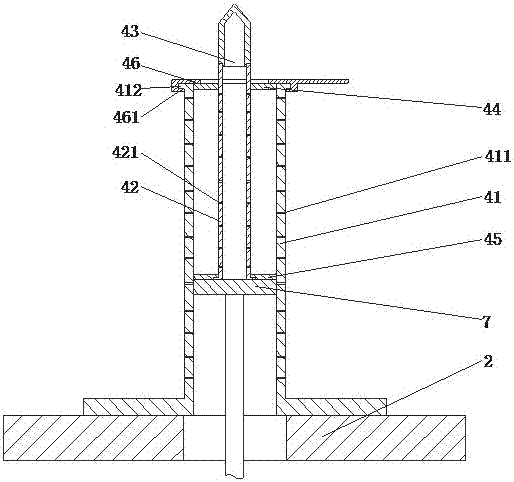

[0030] Such as figure 1 As shown, a rotary processing table for oil filter element of the present invention includes a frame 1, on which a rotary table 2 is arranged, and the center of the rotary table 2 is sleeved on a rotating shaft 3 and rotates around the rotating shaft, turning The end face of the platform 2 is provided with more than three processing positions 21, and each processing position is provided with a compacting tool 4 for the filter element.

[0031] The present invention adopts the above-mentioned structure, and by setting more than three processing positions 21 on the rotary table 2, each processing position is provided with a compacting tool 4 for the filter element, so that each time the filter element is compacted and left for maintenance, the Another filter element is prepared on the compacting tool 4 on other processing stations, making full use of time and improving work efficiency; and the preparation of multiple filter elements is realized on one rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com