Assembling production line for automobile EPS electric power steering column

An electric power steering, production line technology, applied in electric steering mechanisms, mechanical steering gears, etc., to achieve the effects of high transmission efficiency, smooth movement, strong resistance to shock and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

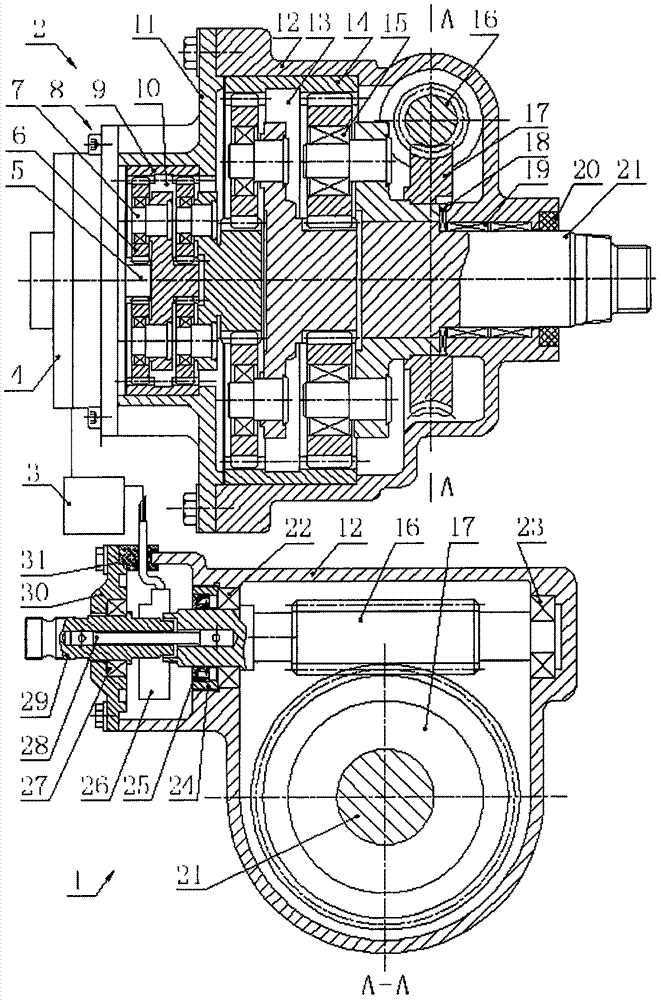

[0008] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description. Such as figure 1As shown, the automobile EPS electric power steering column assembly line includes a steering control system 1 and a steering assist system 2 . The steering assist system 2 includes a booster motor controller 3 , a booster motor 4 , a multi-stage planetary reduction mechanism 8 and a steering gear output shaft 21 . In the present invention, the power steering system 2 and the steering control system 1 adopt two different types of speed reduction mechanisms, and the output torques act on the output shaft 21 of the steering gear together with two independent transmission lines. Specifically, the output torque of the booster motor 4 is decelerated and increased by the shaft extension end of the booster motor 4 through the multi-stage planetary reduction mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com