A Novel Polarized Uncooled Infrared Focal Plane Detector and Its Preparation Method

A focal plane detector, uncooled infrared technology, used in instruments, measuring devices, electrical solid devices, etc., can solve the problems of complex optical path system, complex optical components, difficult design, etc., to simplify the optical system and reduce the number of optical components. , to achieve the effect of monolithic integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The present invention proposes a novel uncooled infrared focal plane detector pixel structure preparation method, comprising the following steps:

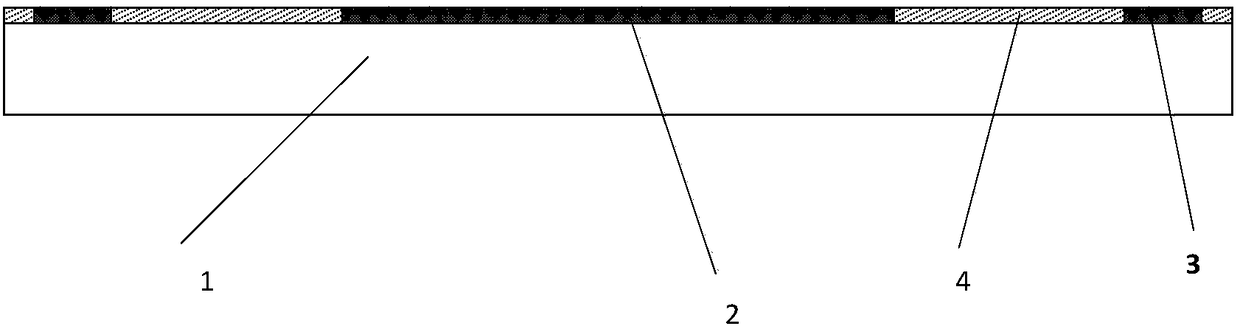

[0075] Step 1: Fabricate a metal reflective layer 2 on the semiconductor base 1 containing the readout circuit; and pattern the metal layer, and the patterned metal reflective layer forms several metal blocks 3; the metal block 3 and the semiconductor base 1 The electrical connection of the readout circuit on the surface; the insulating medium layer 4 is deposited on the patterned metal reflective layer 2; the thickness of the metal reflective layer 2 is The reflective layer metal has a reflectivity of more than 99% for infrared light with a wavelength of 8-14um; the insulating medium layer 4 is a silicon nitride film or a silicon oxide film with a thickness of

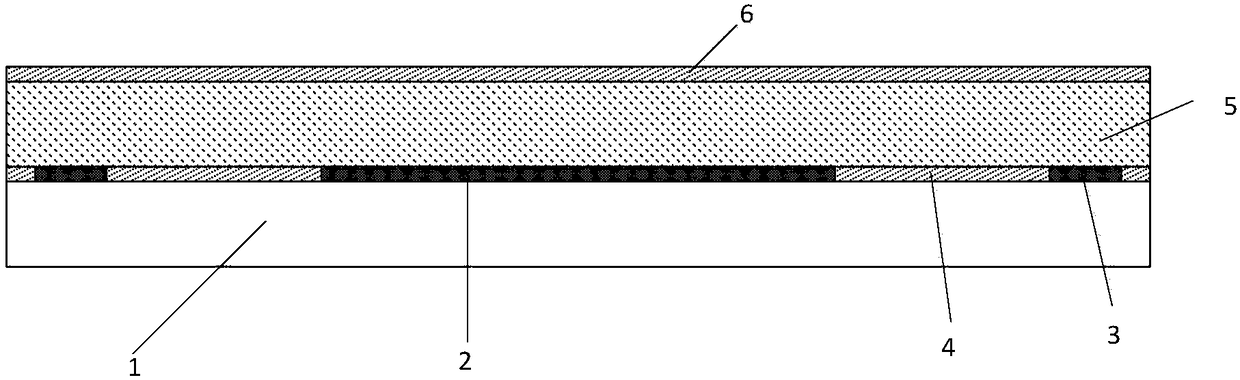

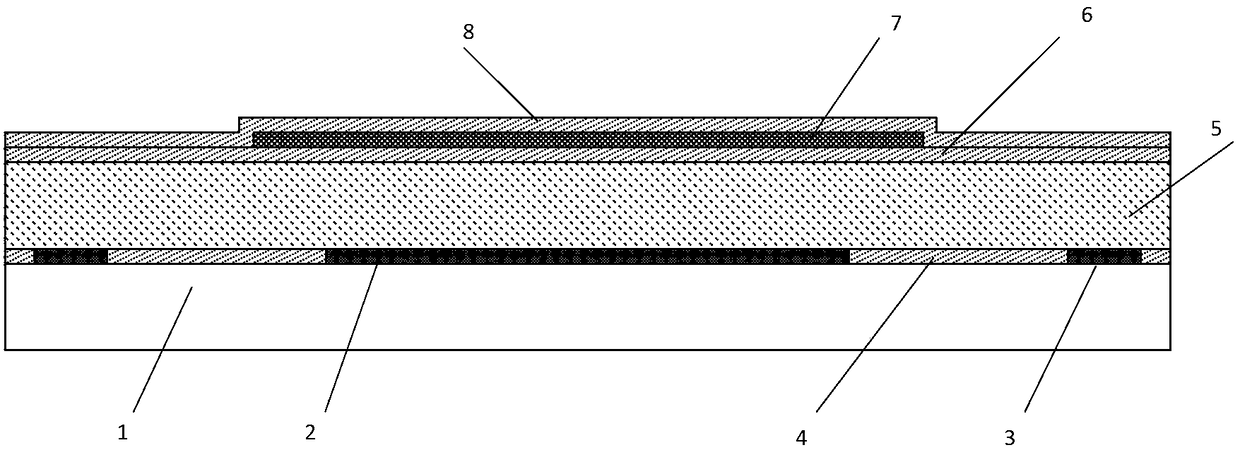

[0076] Step 2: sequentially depositing a first sacrificial layer 5, a first supporting layer 6, a heat sensitive layer 7 and a first protective layer 8 on the in...

Embodiment 2

[0087] The difference from Example 1 is that in step 10, when preparing the metal grating structure, a metal thin film is first deposited or sputtered on the grating support layer by physical vapor deposition or sputtering, and then etched by a dry etching process. Eclipse grating graphics, the grating graphics can be straight or curved, such as Figure 10-12 shown, its angle can be changed and is not limited to Figure 10-12 For several types shown in , the interval between adjacent gratings is 10-500 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com