Low-cost Q390 medium and thick plate and production method thereof

A production method and low-cost technology, applied in the field of iron and steel production, can solve problems such as steel consumption, achieve the effects of improving the pass rate, reducing resource consumption, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

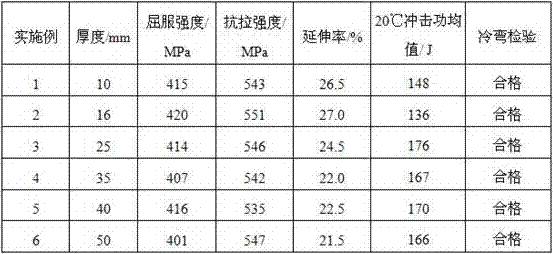

[0015] The inspection standard of the low-cost Q390 medium-thick plate of the present invention is GB / T 1591-2008 "Low Alloy High-Strength Structural Steel", and the performance requirements of the steel plate with a thickness of 50 mm or less are shown in Table 1.

[0016] Table 1: National standard requirements for performance of steel plates with a thickness of 50 mm or less

[0017]

[0018] The present invention will be described in further detail below in conjunction with specific examples.

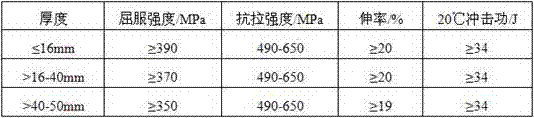

[0019] Embodiment 1-6: Low-cost Q390 medium-thick plate and its production method adopt the following specific process.

[0020] (1) The low-cost Q390 medium-thick plate is prepared through smelting, continuous casting, heating, rolling and cooling processes; the heating process, the heating temperature is 1200-1260 °C; the rolling process, the finishing rolling start temperature is ≤950 °C , the final rolling temperature is 770-800 ° C; the cooling process is cooled by ultra-fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com