Environmentally-friendly baking method of lamb legs

A lamb leg roasting technology, which is applied in the field of meat roasting, can solve problems such as uneven heating, low roasting efficiency, and poor quality, and achieve the effects of ensuring food safety, improving heating efficiency, and maintaining nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

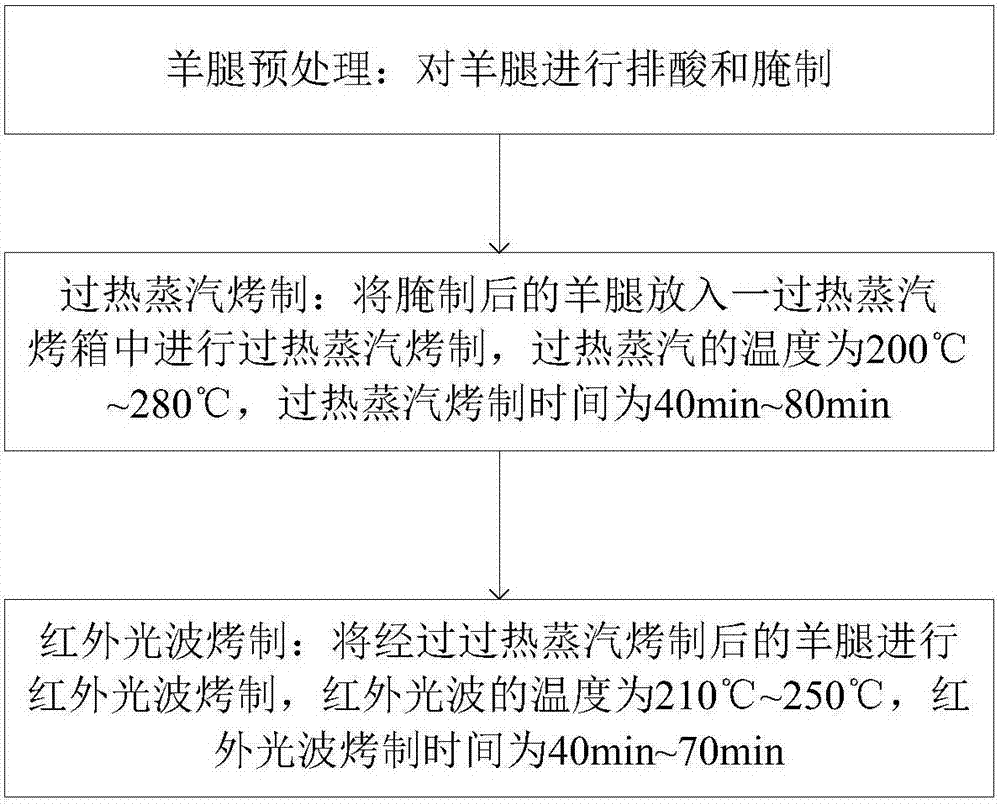

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 traditional method grilled leg of lamb (charcoal grilled)

[0034] (1) Sampling: Collect mutton samples at the slaughterhouse, transport them back in a cold storage truck, and store them at -20°C for later use;

[0035] (2) Thawing: Thaw in a refrigerator at 4°C for 8 hours;

[0036] (3) Pickling: After thawing, add 1% edible salt to the leg of lamb, mix well, put it on a plate placed in a refrigerator at 4°C, and dry-cure for 12 hours;

[0037] (4) charcoal grilling: put the leg of lamb obtained in step 3) on a grill and roast for 60 minutes to obtain the product;

Embodiment 2

[0038] Example 2 Microwave infrared roasted leg of lamb

[0039] (1) Sampling: Collect mutton samples at the slaughterhouse, transport them back in a cold storage truck, and store them at -20°C for later use;

[0040] (2) Thawing: Thaw in a refrigerator at 4°C for 8 hours;

[0041] (3) Cooking: put the leg of lamb obtained in step 2) into boiling water and boil for 50 minutes;

[0042] (4) Microwave roasting: put the leg of lamb obtained in step 3) into an infrared oven and roast for 30 minutes to obtain the product;

[0043] The determination of heterocyclic amines was carried out on the roasted leg of lamb obtained in the above 1-2 examples, and it was found that the total amount of heterocyclic amines was as high as 619.38ng·g -1 , and the specific content detection results are shown in Table 1.

[0044] Table 1 Heterocyclic amine content of lamb leg roasted on open fire and microwave infrared roasted

[0045]

Embodiment 3

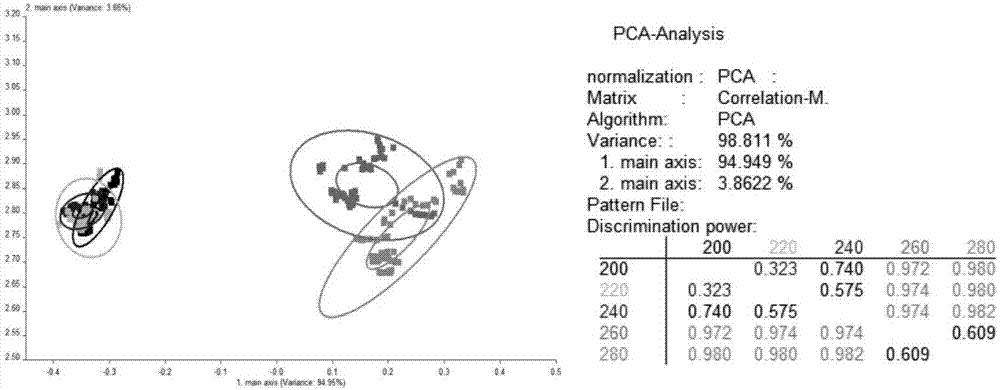

[0046] Example 3 Lamb leg roasted with superheated steam combined with infrared light (superheated steam roasting temperature 200°C)

[0047] (1) Sampling: Collect mutton samples at the slaughterhouse, transport them back in a cold storage truck, and store them at -20°C for later use;

[0048] (2) Thawing: Thaw in a refrigerator at 4°C for 8 hours;

[0049] (3) Pickling: After thawing, add 1% edible salt to the leg of lamb, mix well, put it on a plate placed in a refrigerator at 4°C, and dry-cure for 12 hours;

[0050] (4) Baking with superheated steam: put the leg of lamb obtained in step 3) into an oven preheated with superheated steam at 200°C, and bake for 60 minutes;

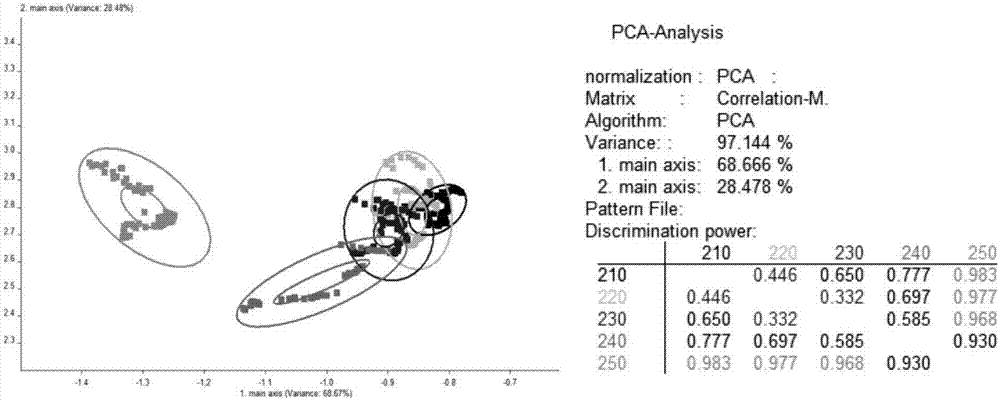

[0051] (5) Infrared light wave roasting: replace the half-cooked roasted leg of lamb obtained in step (4) into an infrared light wave baking tray, put it into the same oven preheated by infrared light wave at 240°C, and bake for 60 minutes to obtain the product.

[0052] a) Table 1 oven parameter setting:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com