Method and system for machining multiple holes in large-sized global shell

A hole processing method and processing system technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem of lack of high-precision processing methods for large-sized spherical shells, and achieve improved processing accuracy and reliability. The effect of ensuring machining accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiment of the present application solves the technical problem of the lack of high-precision machining methods for large-scale spherical shells in the prior art by providing a method and system for processing large-scale spherical shells with holes; The technical effect of machining accuracy.

[0038] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

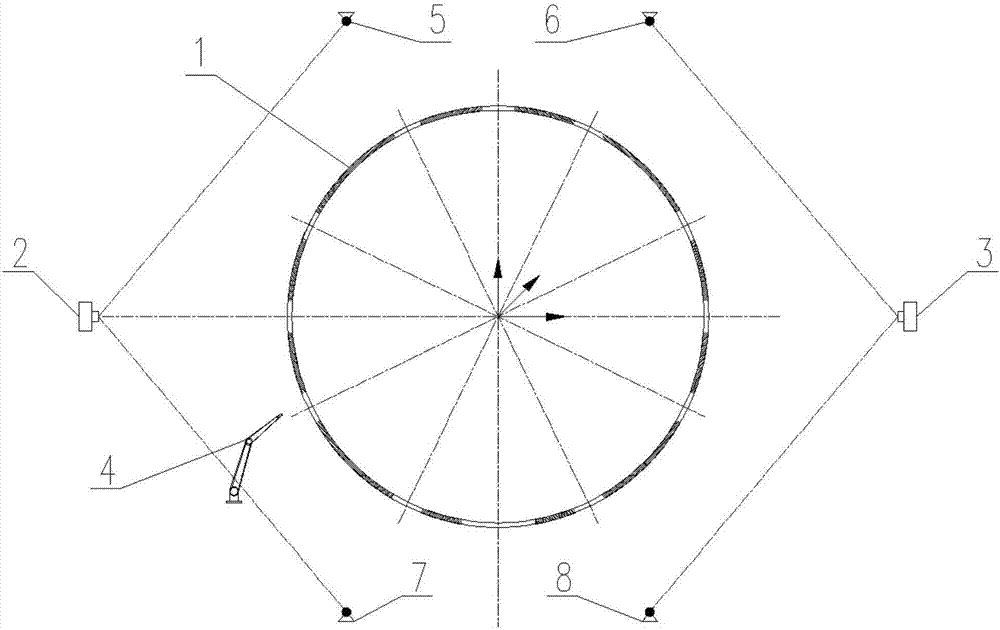

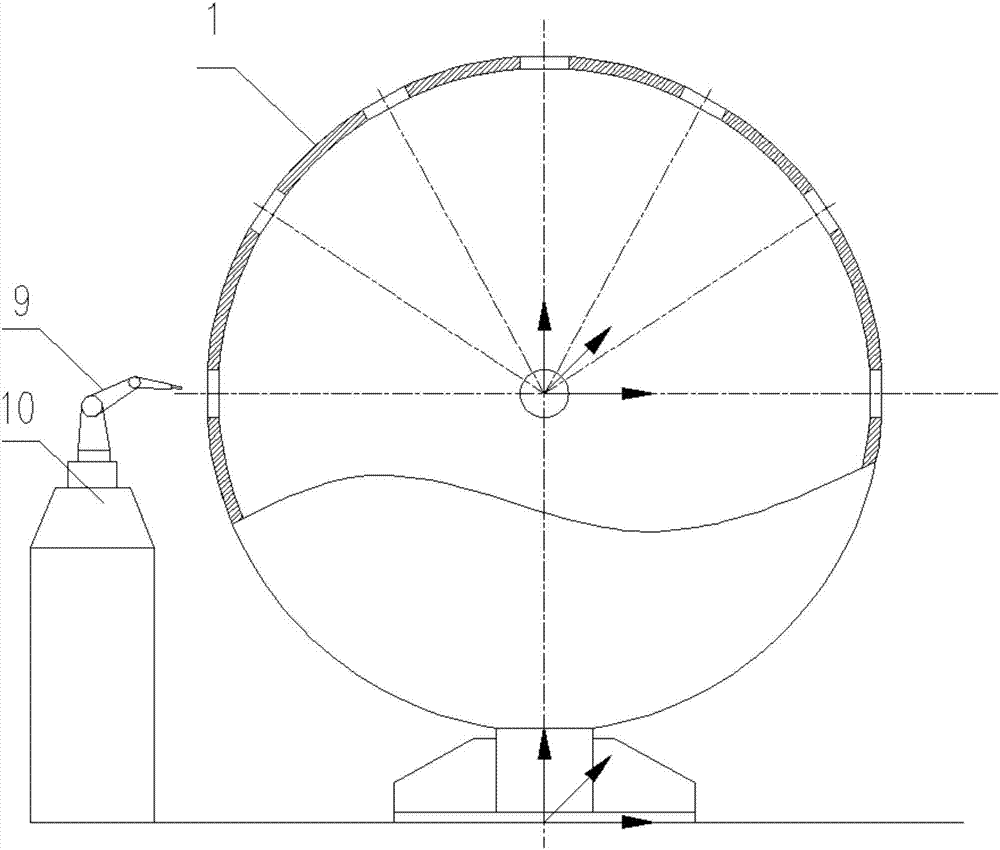

[0039] Through the measurement based on the three-dimensional space coordinate system, the large spherical shell is converted into three-dimensional data; and the processing system is positioned in the three-dimensional space coordinate system; the machining accuracy is greatly improved; at the same time, by combining the theoretical model of the target processing with the large spherical The three-dimensional data information comparison of the shell screens out the processing coordinates expressed based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com