Radial tire for low-section loading

A radial tire and low-section technology, applied to tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as irregular mesh structure, reduced tire durability, and chaotic cord arrangement, and achieve improved The effect of tire uniformity, reducing stress concentration, and increasing impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

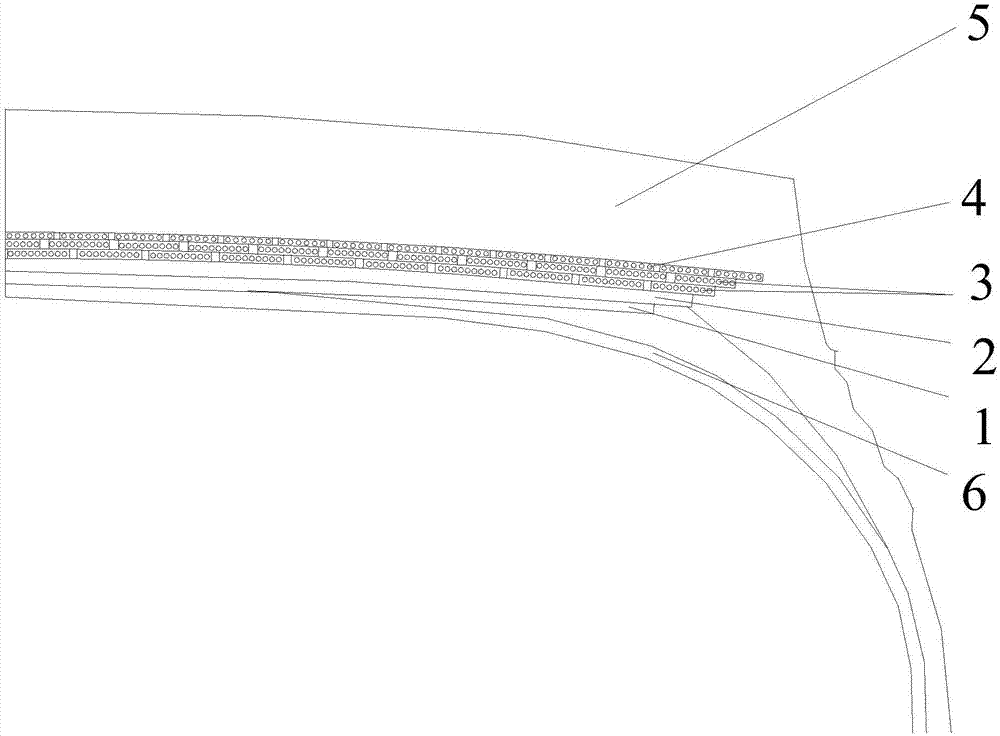

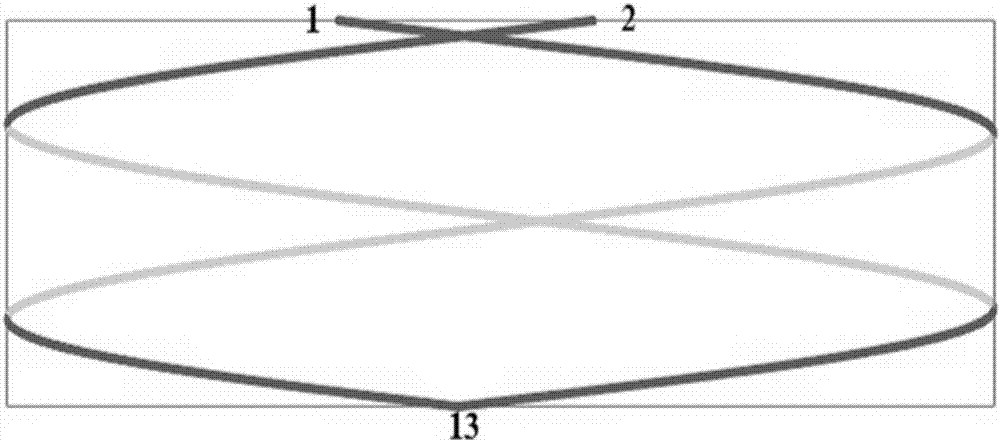

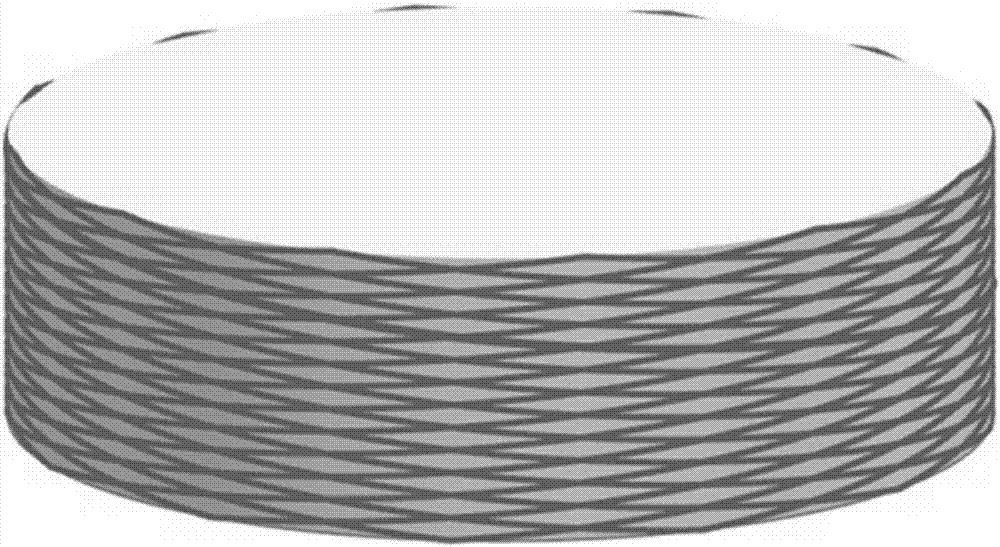

[0016] In view of the above problems, the present invention provides that the tire adopts a four-layer belt structure. attached figure 1 As shown, a radial tire for low-profile trucks, the tire includes a carcass 6, a tread 5 and a belt layer, the belt layer includes 1# belt layer 1, 2# belt layer 2, 3# belt Layers 3 and 4# belt layer 4, 1# belt layer 1, 2# belt layer 2, 3# belt layer 3 and 4# belt layer 4 are wound on the carcass 6 in turn, 3# belt layer Layer 3 is a "zigzag" winding reinforcing layer, which is arranged on the 2# belt layer, and above the "zigzag" winding layer is a 4# belt layer 4 with a spiral winding structure, which is used to constrain and protect the mesh structure.

[0017] The present invention is a reinforced belt structure for low-section heavy duty radial tires (attached figure 1 ), which is a four-layer belt structure. The 1# belt layer 1, 2# belt layer 2 are attached to the carcass 6 in turn, and the 3# belt layer 3 is a "zigzag" winding reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com