Coaxial tube assembly for truck

A technology of coaxial tubes and components, applied in vehicle components, heating/cooling equipment, air handling equipment, etc., can solve problems such as installation difficulties, obstructions, and easy deformation, so as to facilitate observation, avoid pipeline deformation, and improve assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

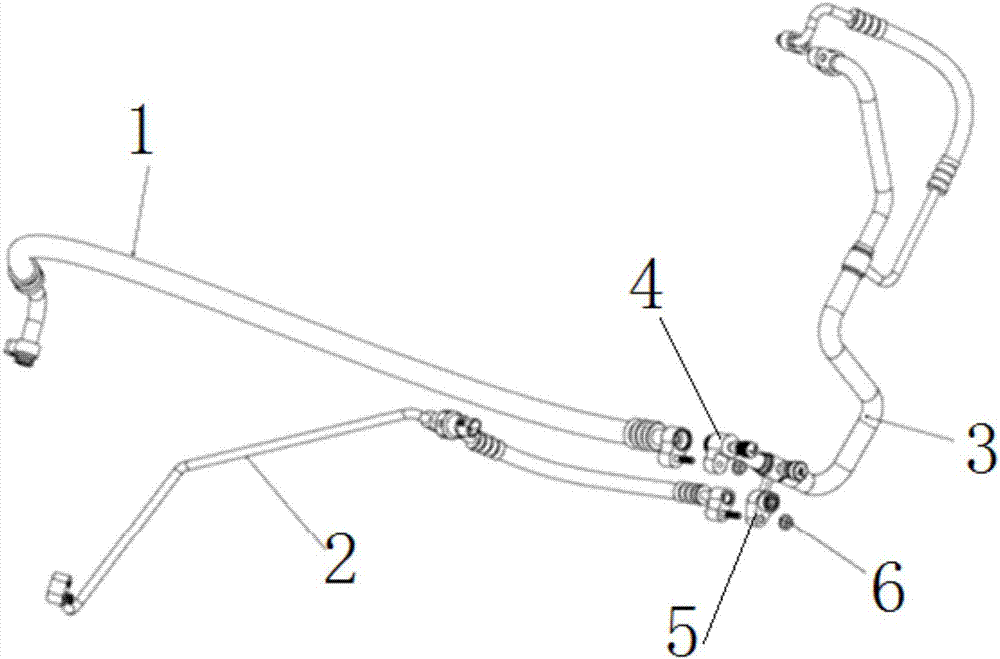

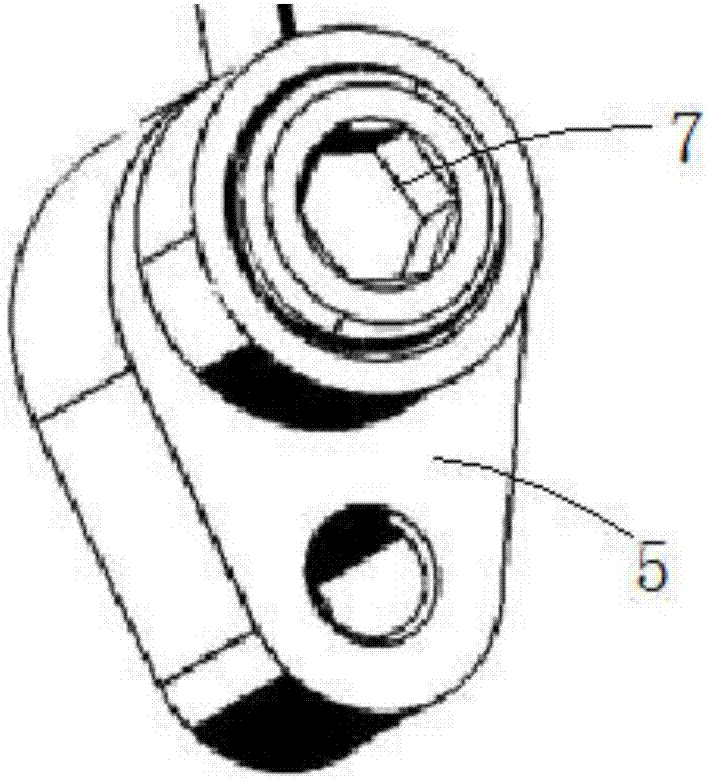

[0014] Such as figure 1 with figure 2 As shown, the present invention provides a truck coaxial pipe assembly, including: a suction pipe 1 for connecting a compressor, a liquid pipe 2 for connecting a condenser, a coaxial pipe 3, a first flange 4, a second Flange 5, and sight glass 7;

[0015] The suction pipe 1 communicates with the coaxial pipe 3 through the first flange 4, the liquid pipe 2 communicates with the coaxial pipe 3 through the second flange 5, and the sight glass 7 is integrated in the first On the second flange 5.

[0016] Specifically, the truck coaxial pipe assembly further includes nuts 6 for fixing the first flange 4 and the second flange 5 .

[0017] Specifically, the suction pipe 1 communicates with the inner cavity of the coaxial tube 3 , and the liquid tube 2 communicates with the outer cavity of the coaxial tube 3 .

[0018] Specifically, the truck coaxial pipe assembly of the present invention can avoid pipeline deformation during vehicle assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com