Method for extracting aluminum sulfate, aluminum potassium sulfate, rubidium sulfate and cesium sulfate by aid of leaching agents of lithium mica sulfuric acid

A technology of aluminum potassium sulfate and lepidolite, which is applied in the fields of aluminum sulfate, chemical instruments and methods, rubidium/cesium/francium compounds, etc., and can solve problems such as extraction of aluminum sulfate and cesium sulfate that have not yet been discovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

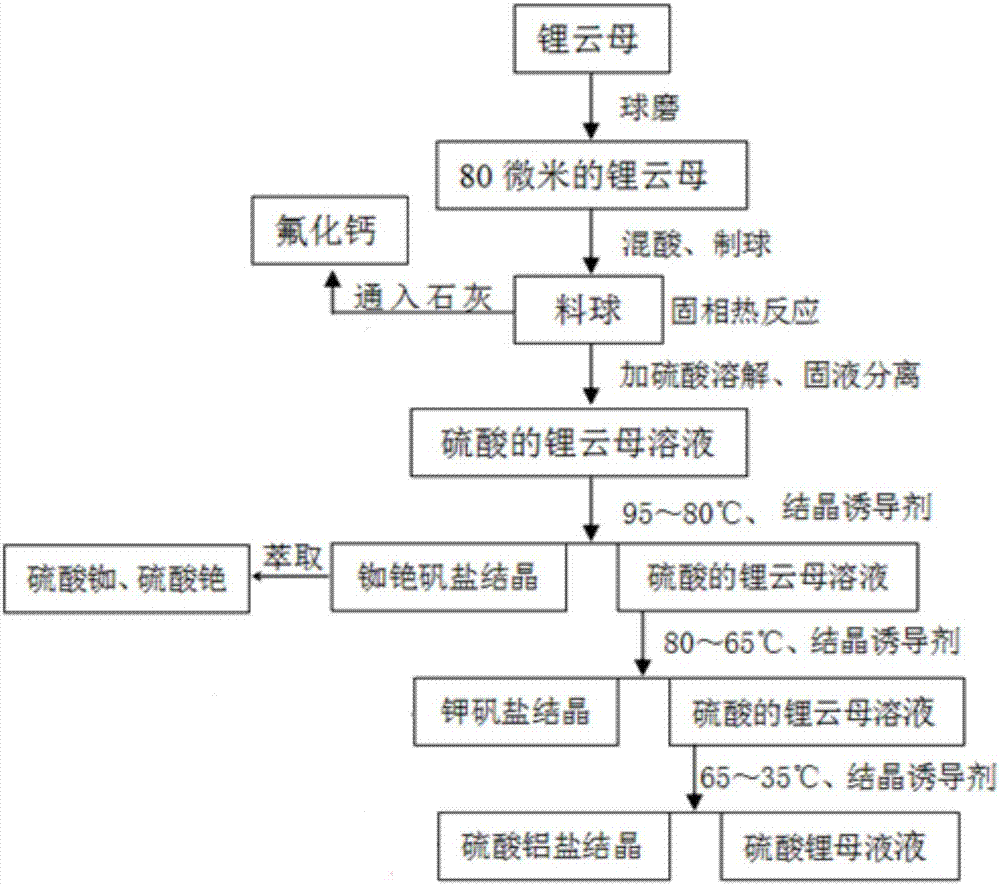

[0035] Such as figure 1 As shown, the method for extracting aluminum sulfate, aluminum potassium sulfate, rubidium sulfate and cesium sulfate using lepidolite sulfuric acid leaching solution provided in this embodiment comprises the following steps:

[0036] (1) Ball milling activation of lepidolite

[0037] The lepidolite is ball-milled to 200 mesh, and the iron is removed by an iron remover to obtain lepidolite powder for subsequent use;

[0038] (2) Sulfuric acid solid-phase thermal reaction

[0039] Mix the lepidolite powder obtained in step (1) with concentrated sulfuric acid solution with a mass concentration of 95% to obtain a mixture, then make the mixture into balls to obtain pellets, then heat the pellets to 300°C, and keep the Insulation reaction for 6 hours, the gas generated during the heating process is passed into lime water;

[0040] Among them, the mass ratio of lepidolite powder to concentrated sulfuric acid solution with a mass concentration of 95% is 1.2...

Embodiment 2

[0051] The method for extracting aluminum sulfate, potassium aluminum sulfate, rubidium sulfate and cesium sulfate by utilizing lepidolite sulfuric acid leaching solution provided in this embodiment comprises the following steps:

[0052] (1) Ball milling activation of lepidolite

[0053] The lepidolite is ball-milled to 100 mesh, and iron is removed by an iron remover to obtain lepidolite powder for subsequent use;

[0054] (2) Sulfuric acid solid-phase thermal reaction

[0055] Mix the lepidolite powder obtained in step (1) with concentrated sulfuric acid solution with a mass concentration of 97% to obtain a mixture, then make the mixture into balls to obtain pellets, then heat the pellets to 350°C, and keep Insulation reaction for 6 hours, the gas generated during the heating process is passed into lime water;

[0056] Among them, the mass ratio of lepidolite powder to concentrated sulfuric acid solution with a mass concentration of 97% is 1.1:1;

[0057] (3) Dilute sulf...

Embodiment 3

[0067] The method for extracting aluminum sulfate, potassium aluminum sulfate, rubidium sulfate and cesium sulfate by utilizing lepidolite sulfuric acid leaching solution provided in this embodiment comprises the following steps:

[0068] (1) Ball milling activation of lepidolite

[0069] The lepidolite is ball-milled to 400 mesh, and the iron is removed by an iron remover to obtain lepidolite powder for subsequent use;

[0070] (2) Sulfuric acid solid-phase thermal reaction

[0071] Mix the lepidolite powder obtained in step (1) with concentrated sulfuric acid solution with a mass concentration of 92% to obtain a mixture, then make the mixture into balls to obtain pellets, then heat the pellets to 400°C, and keep the Heat preservation reaction for 5 hours, and the gas generated during the heating process is passed into lime water;

[0072] Among them, the mass ratio of lepidolite powder to concentrated sulfuric acid solution with a mass concentration of 92% is 1.05:1;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com