Energy-saving-type backflow prevention system

An energy-saving, check valve technology, used in water supply pipeline systems, water supply installations, buildings, etc., can solve problems such as large workload, large spring pressure, long maintenance time, etc., to reduce water loss, reliable sealing, and opening. Close the relaxing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

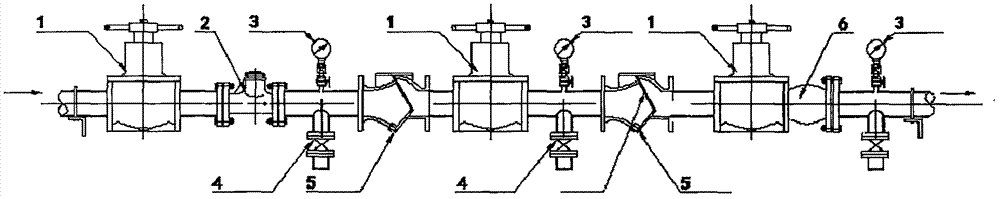

[0019] see figure 1 , the working principle of an energy-saving backflow prevention system described in a preferred embodiment of the present invention is as follows:

[0020] An energy-saving backflow prevention system of the present invention includes a gate valve, a water meter 2 connected to the gate valve, the water meter 2 is connected to a Y-shaped filter for filtering water, rubber joints are installed at the end of the pipeline, and the gate valve on the water inlet pipeline is changed to The rotary cutting valve 1 is connected to the water meter 2 through the pipeline, and the water meter 2 is connected to the rubber flap check valve 5 for preventing the water from flowing backward.

[0021] The system includes an upstream part, a midstream part, and a downstream part. The upstream part includes a rotary cut valve 1, a water meter 2, and a rubber flap check valve 5. A pressure gauge 3 and a pressure gauge 3 are installed on the pipeline between the water meter 2 and ...

Embodiment 2

[0024] An energy-saving backflow prevention system, including a gate valve, a water meter 2 connected to the gate valve, the water meter 2 connected to a Y-shaped filter for filtering water, a rubber joint is installed at the end of the pipeline, and the gate valve on the water inlet pipeline is changed to a rotary cut valve 1 , The rotary valve 1 is connected to the water meter 2 through the pipeline, and the water meter 2 is connected to the rubber disc check valve 5 for preventing the water from flowing backward.

[0025] The system includes an upstream part, a midstream part, and a downstream part. The upstream part includes a rotary cut valve 1, a water meter 2, and a rubber flap check valve 5. A pressure gauge 3 and a pressure gauge 3 are installed on the pipeline between the water meter 2 and the rubber flap check valve 5. Drain valve 4; the midstream part includes rotary cut valve 1, the downstream part includes rubber disc check valve 5 and rotary cut valve 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com