Corrosion simulation system under synergistic effect of marine environment and oil-gas medium

A synergistic and marine environment technology, applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problem of single performance, inability to reproduce the synergistic corrosion damage of the internal and external environment of materials, lack of simulation characterization of underwater oil and gas extraction devices, etc. problem, to achieve the effect of ensuring the accuracy of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

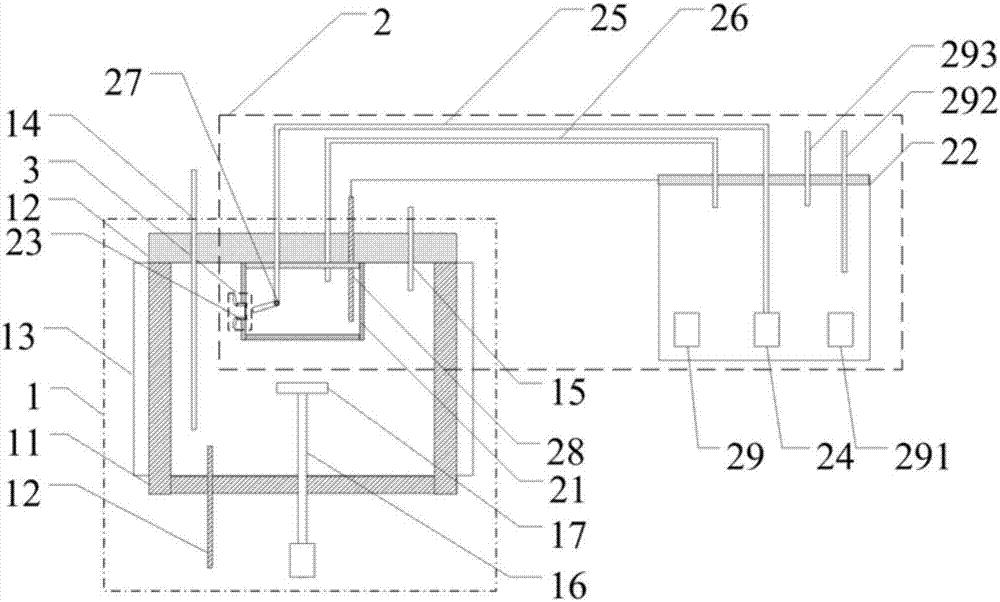

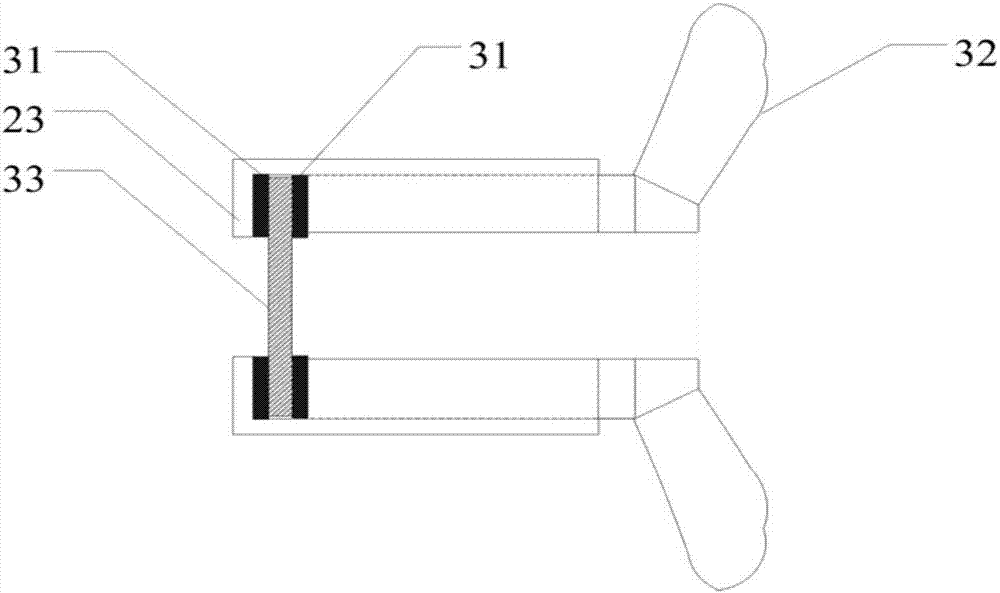

[0021] see figure 1 The marine environment and oil-gas medium synergistic corrosion simulation system provided by the present invention includes a high-temperature and high-pressure oil-gas corrosion simulation device 1 , a seawater corrosion simulation device 2 and a sample installation assembly 3 . In the test, the oil and gas corrosion simulation high temperature and high pressure device 1 is used to simulate the H 2 S, CO 2 , Cl - Corrosion environment such as solution, gas, temperature and flow rate, seawater corrosion simulation device 2 can realize environment simulation of seawater corrosion environment solution, dissolved oxygen, temperature and erosion velocity angle, etc. Corrosion simulation environment, so as to realize the synergistic corrosion simulation of marine and oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com