Locomotive traction inverter

A traction inverter and locomotive technology, which is applied in the conversion of equipment structural parts, AC power input into DC power output, cooling/ventilation/heating transformation, etc., can solve the difficulty of high power density, locomotive traction inverter structure Not the same and other problems, to achieve the effect of satisfying the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

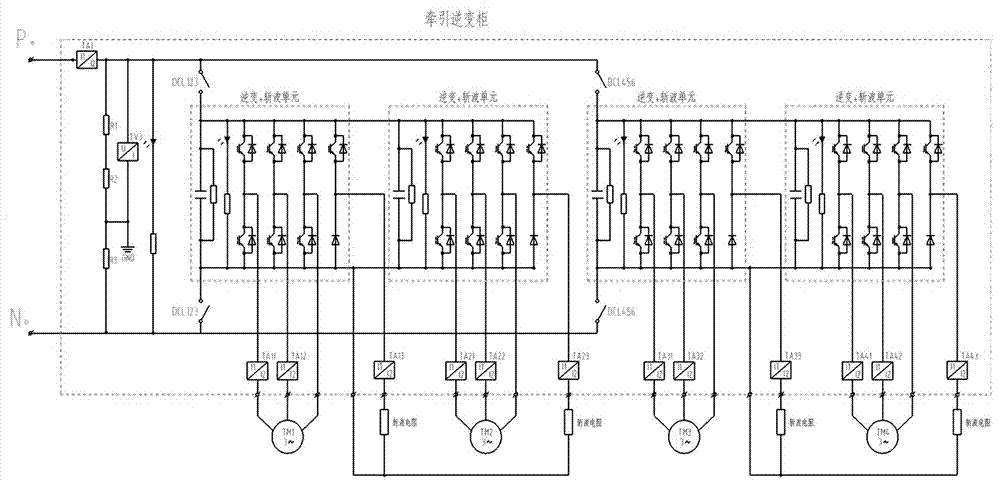

[0014] It can be seen from Figure 2 that the traction inverter has other auxiliary circuits besides four 500KW inverter choppers. From the perspective of the main technical requirements of the traction inverter, it is very difficult to arrange four inverter choppers in such a small space, and it also needs to adopt an air-cooled structure.

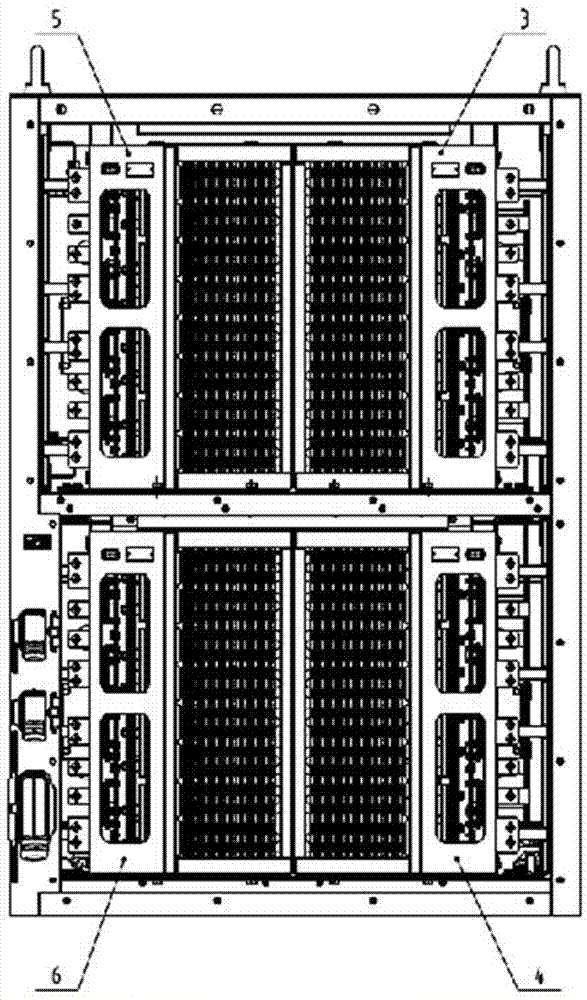

[0015] In order to optimize the design, the traction inverter adopts a modular design, including 4 power inverter output and chopper braking units, 1 traction motor and power frequency power supply conversion switch, 1 grounding detection unit, and 5 high-voltage indicating devices , and forced air cooling unit, safety discharge protection and related detection unit.

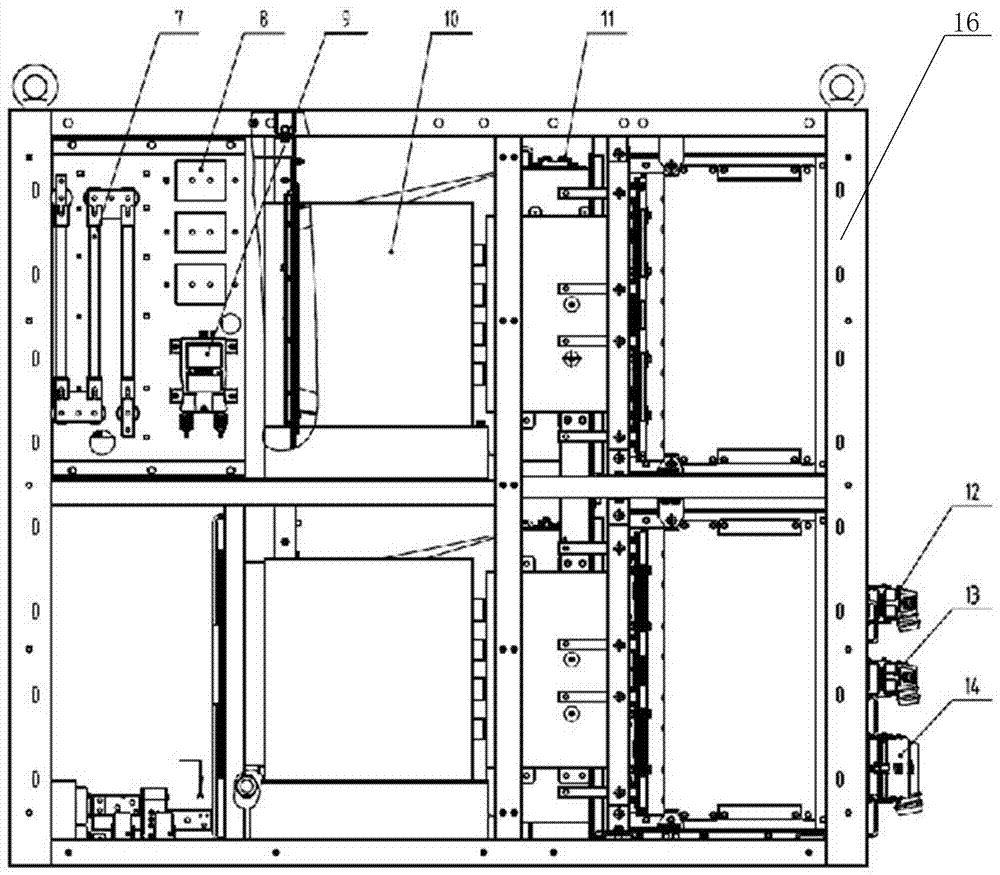

[0016] Specifically, the layout scheme is that the locomotive traction inverter includes a cabinet body 16, and the cabinet body 16 is div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com