Wire control device and manufacturing method of shell assembly thereof

A technology of wire control device and shell assembly, which is applied in the direction of cabinet/cabinet/drawer parts, electrical components, closed cabinet, etc., can solve the problems of complex connection structure, troublesome installation and disassembly, limited modeling space, etc. , to achieve the effect of convenient installation and disassembly, convenient after-sales maintenance, and large modeling space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

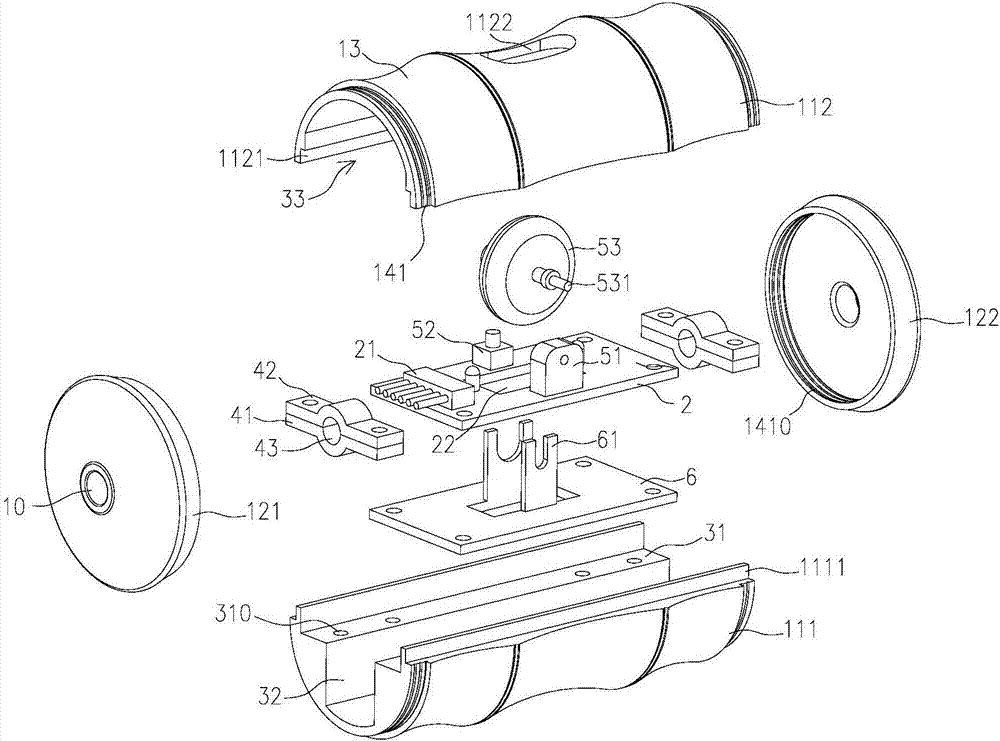

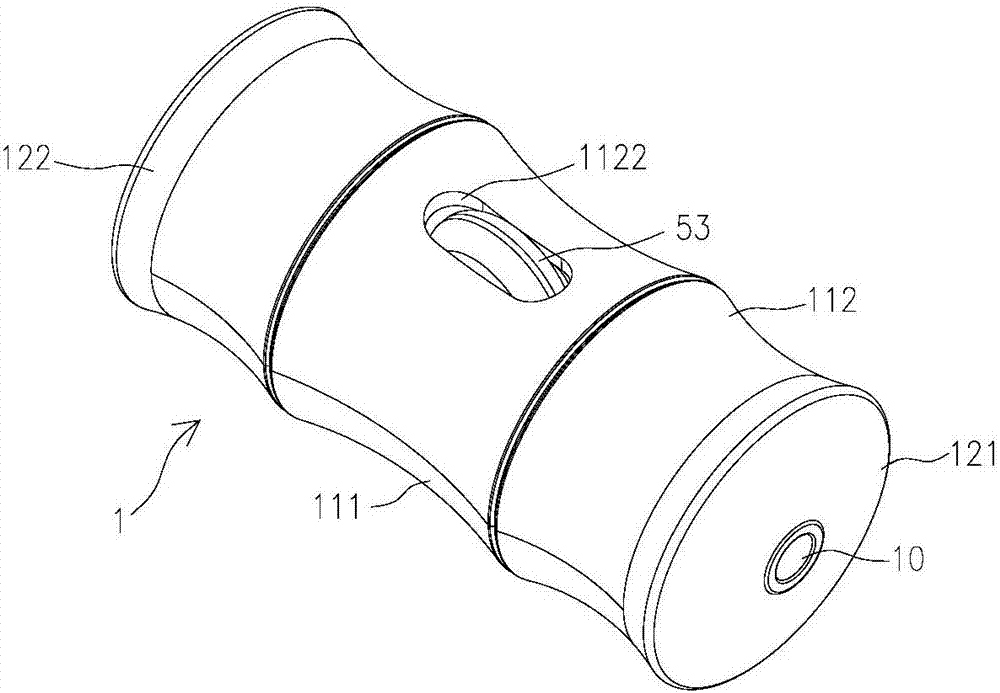

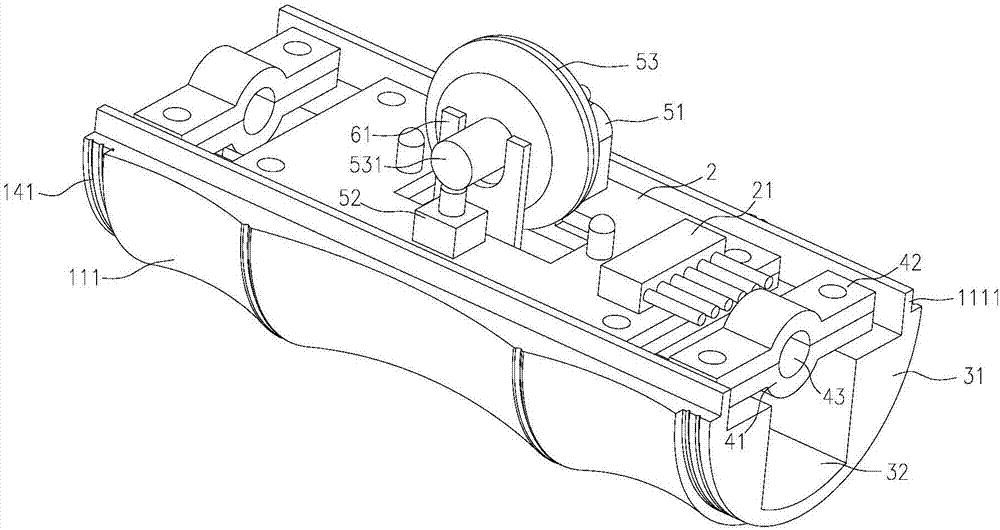

[0046] see Figures 1 to 7 , the wire control device of the present invention includes a housing assembly 1 and a wire control circuit board 2, the housing assembly 1 is provided with an electrical component cavity 3, the axial cross-sectional structure of the electrical component cavity 3 is the same, and the wire control circuit The board 2 is placed in the electrical component cavity 3, the housing assembly 1 is provided with a wire passage 10 connecting the electrical component cavity 3 and the outside world, the wire control circuit board 2 is provided with a terminal 21, and the housing assembly The assembly 1 includes a shell and an end cover. The shell includes a first shell 111 and a second shell 112 that are relatively assembled. The first shell 111 and the second shell 112 are formed by metal extrusion. The end cover includes a first end cover 121 and a second end cover 122. After the first shell 111 and the second shell 112 are assembled, the two ends thereof are f...

Embodiment 2

[0056] The difference between this implementation and the first implementation is that the first housing 111 and the second housing 112 are injection molded, and the circuit board installation recess 31, the electrical component slot 33, the splicing structure and the wire slot 32 are compatible with the first housing 111. It is integrally injection molded with the second housing 112 .

Embodiment 3

[0058] The main difference between this embodiment and Embodiment 1 is: see Figure 8 , the wire control circuit board 2 is provided with a power switch button 71 and a power adjustment button, and the position corresponding to the power switch button 71 and the power adjustment button on the second housing 112 is provided with a corresponding button hole (not shown in the figure). ), the power adjustment button includes a power increase button 72 and a power reduction button 73, the power switch button 71, the power increase button 72 and the power reduction button 73 are respectively provided with a button cap, and the button cap extends out of the second housing through the button hole The outside of 112 is controlled by the user, and the power switch button 71 is used to send a switch signal to the main control circuit of the electrical appliance, and the main control circuit of the electrical appliance controls the power on or off according to the signal of the switch; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com