Large-span insulated plastic greenhouse

A plastic greenhouse, large-span technology, applied in greenhouse cultivation, climate change adaptation, gardening and other directions, can solve the problems of increasing the load of plastic greenhouse arches and reducing the safety of the greenhouse structure, so as to improve construction efficiency and quality, and avoid welding. , the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

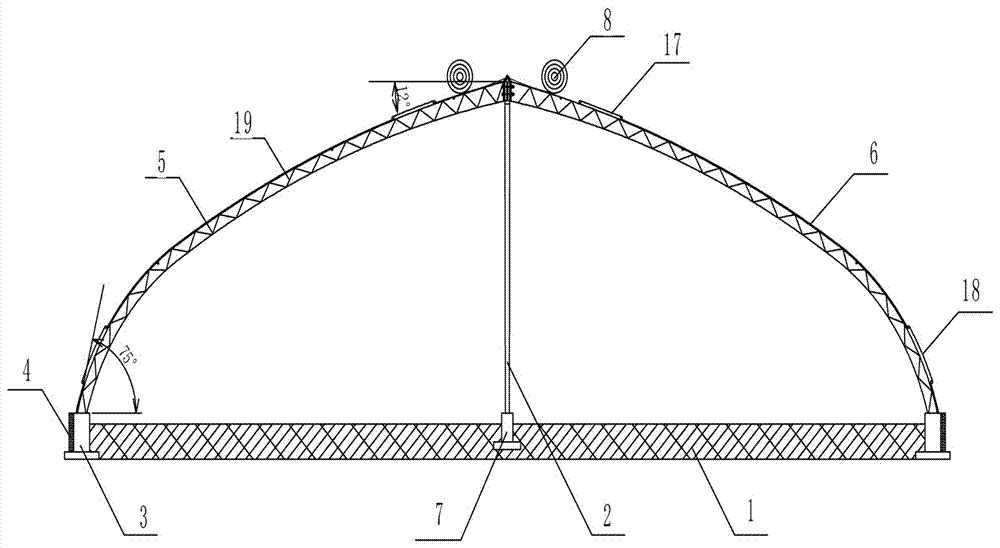

[0037] This embodiment provides a large-span thermal insulation plastic greenhouse, such as figure 1 As shown, it includes some greenhouse arches, some columns 2, some crossbeams 15, plastic film 13 and mechanical roller shutter thermal insulation system.

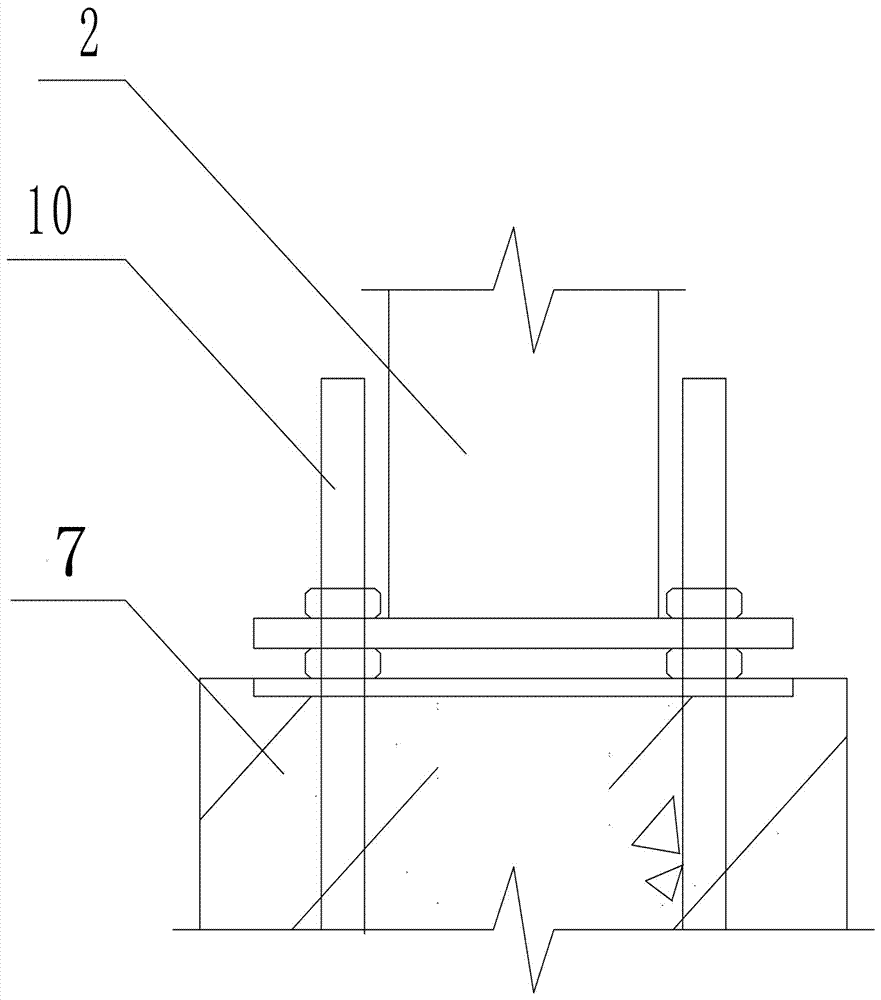

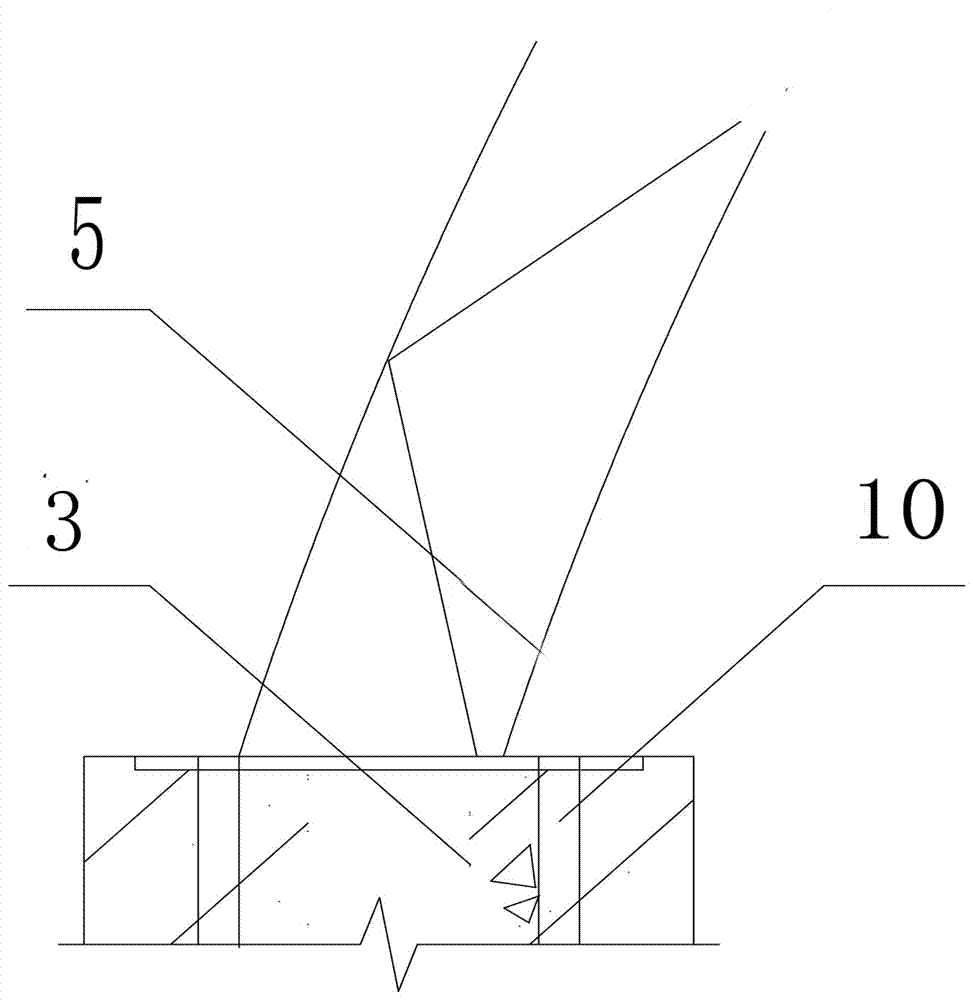

[0038] Such as figure 2 and image 3 As shown, the bottom of the column 2 is fixed on the column fixing foundation pile 7 through the embedded part 10 , and the tops of two adjacent columns 2 are connected and fixed by the crossbeam 15 . The ground surrounded by the arched structure is filled with nutrient soil 1 in the greenhouse. The top of the arched structure is supported by the beam 15 and the angle between the top of the arched structure and the horizontal line is 12 degrees, and the angle between the bottom of the arched structure and the vertical line is 75 degrees; the plastic cladding The membrane 13 and the mechanical roller blind insulation system are arranged on the outside of the arched structure.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com