Pretreatment washing device for coating of aluminum alloy automobile hub

A technology for automobile wheel hubs and cleaning devices, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of high cost of use, large energy consumption, environmental pollution, etc., and achieve low cost and high efficiency. Economic benefits and high heat energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

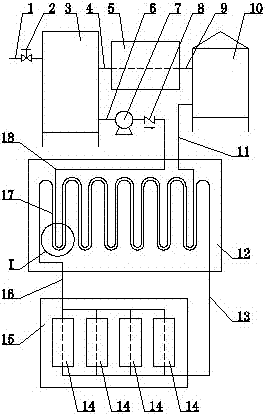

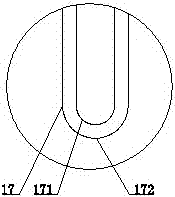

[0008] see Figure 1 to Figure 2 , the present invention includes a cleaning operation box 5, and also includes a water supply pipe 1, a water supply valve 2, a water tank 3, a recovery water pipe 4, a water pump inlet pipe 6, a water pump 7, a check valve 8, a cleaning operation box water inlet pipe 9, and a hot water tower 10 , hot water pipe 11, heat exchanger 12, air compressor inlet coolant pipe 13, air compressor room 15, air compressor outlet coolant pipe 16, heat exchange tube group 17, water pump outlet pipe 18 and several air compressors machine 14, the heat exchange tube group 17 includes a serpentine heat exchange water pipe 171 and a serpentine heat exchange coolant pipe 172, the heat exchange tube group 17 is installed in the heat exchanger 12, and the air compressor 14 is installed in a sealed In the air compressor room 15, the liquid outlet of the air compressor 14 is connected to the left end of the serpentine heat exchange coolant pipe 172 in the heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com