Water-electricity separation system of pulsator semiautomatic washing machine

A water-electricity separation and washing machine technology, applied in the field of washing machines, can solve the problems of low detergent solubility, large washing power, poor washing effect, etc., and achieve the effects of improving safe use performance, convenient heating treatment, and improving use quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

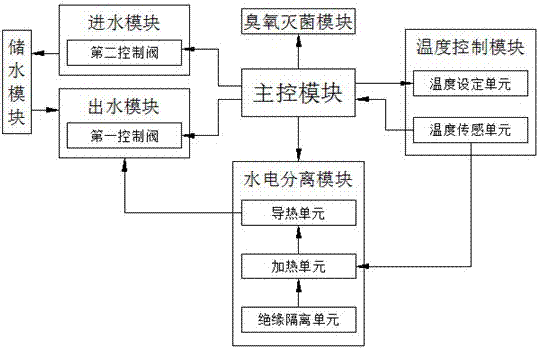

[0014] refer to figure 1 , a water and electricity separation system for a pulsator semi-automatic washing machine, including a main control module, a temperature control module, a water and electricity separation module, an ozone sterilization module and a water storage module, and the output ends of the main control module are respectively connected with the water and electricity separation module and the ozone sterilization module , the water and electricity separation module includes a heat conduction unit, a heating unit and an insulation isolation unit, the input end of the heat conduction unit is connected to the output end of the heating unit, the input end of the heating unit is connected to the output end of the insulation isolation unit, and the temperature control module includes a temperature setting unit and the temperature sensing unit, wherein the input end of the temperature setting unit is connected to the output end of the main control module, the output end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com