Gas producer furnace and gas generating device

A technology of gas generator and furnace body, which is applied in the field of heat treatment, which can solve the problems of slowing down the production rhythm, increasing the construction cost, and increasing the difficulty of operation, and meets the requirements of reducing the height of the factory building, reducing the possibility of shaking, and reducing the difficulty of operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

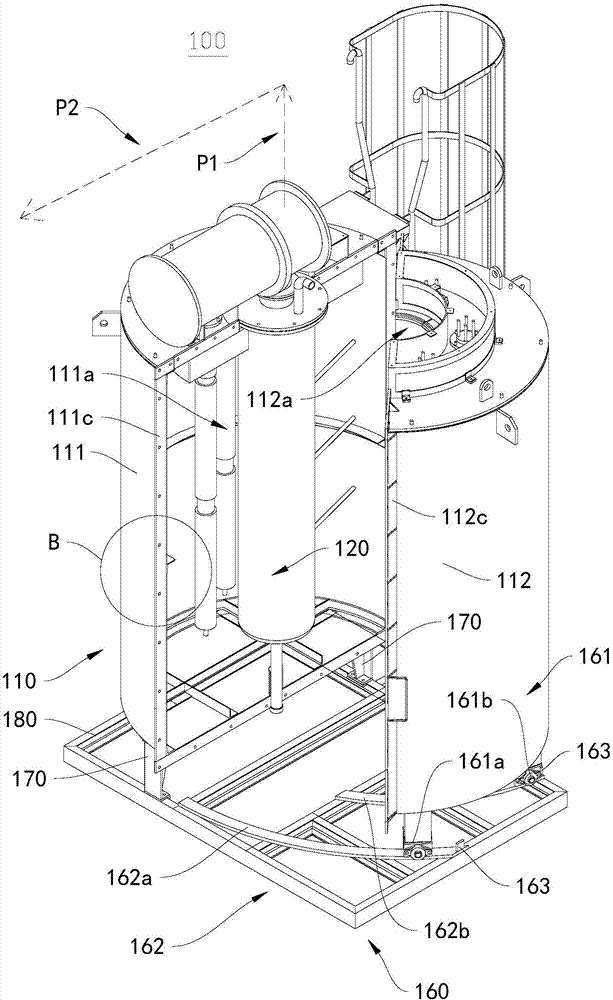

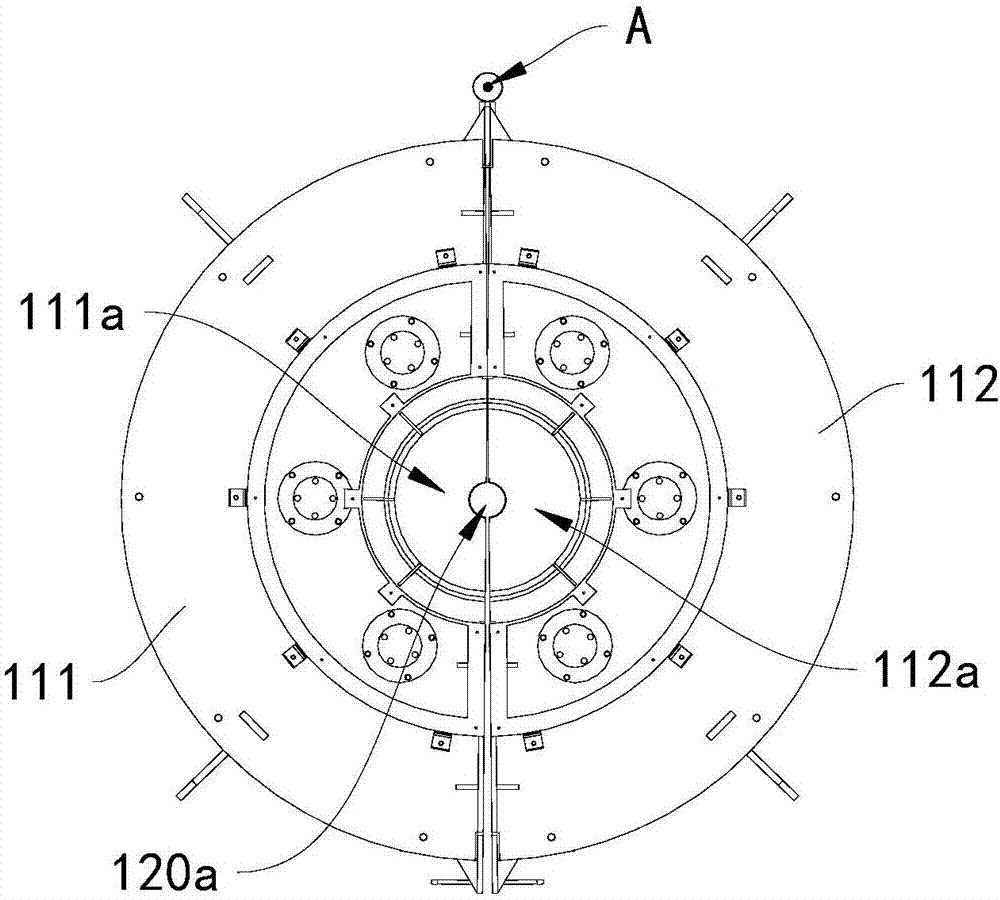

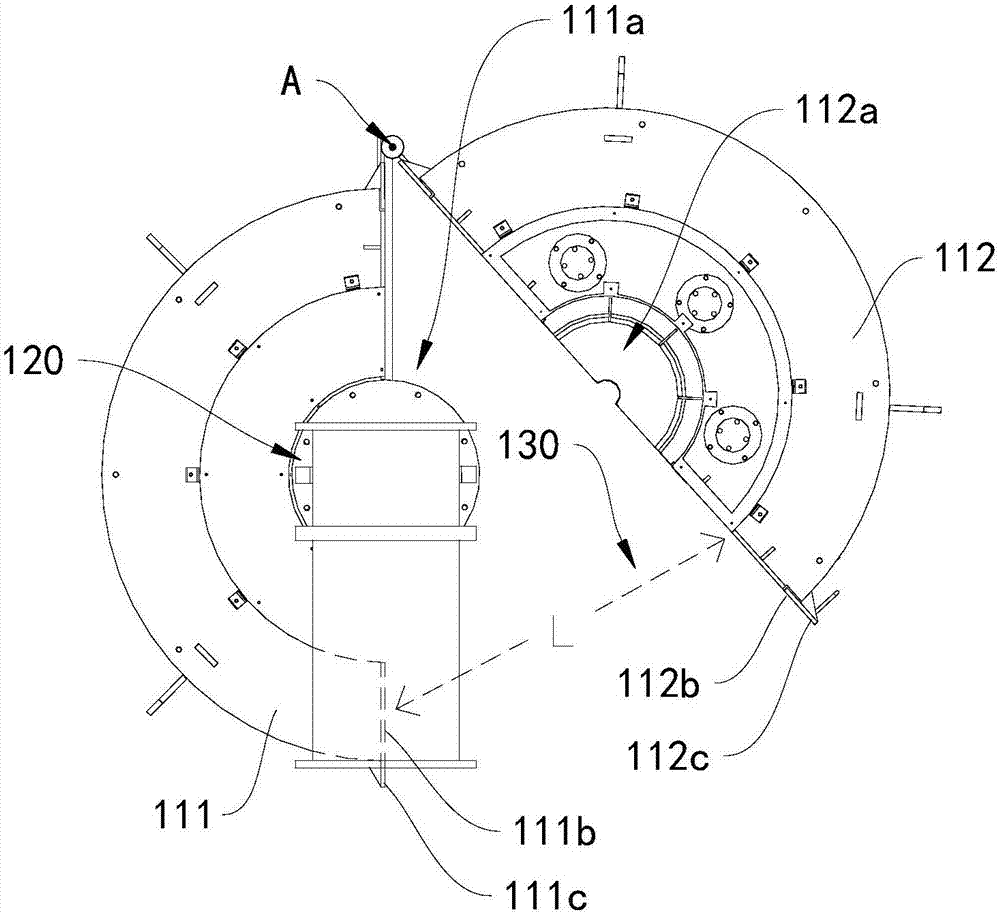

[0043] see figure 1 and figure 2 , this embodiment provides a gas generator 100 . The furnace body 110 of the gas generator 100 includes a first furnace body 111 and a second furnace body 112 . The first furnace body 111 has a first sub-cavity 111a, and the second furnace body 112 has a second sub-cavity 112a. Set cavity 120a. Wherein, the first furnace body 111 and the second furnace body 112 are detachably connected, and the first furnace body 111 and the second furnace body 112 can be separated from each other through disassembly.

[0044] The furnace body 110 of the gas generating furnace 100 is composed of a first furnace body 111 and a second furnace body 112 that can be separated from each other. By separating the first furnace body 111 and the second furnace body 112 from each other, the muffle tank 120 can be separated from The sides of the main body 110 are removed from the accommodating cavity 120 a without being lifted from the top of the furnace main body 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com