Preparation method of tortoise-shell glue

A technology of tortoise shell glue and tortoise shell, applied to medical preparations containing active ingredients, pharmaceutical formulas, unknown raw materials, etc., can solve the problems of high volatile base nitrogen content and long extraction time, and achieve good health care function and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

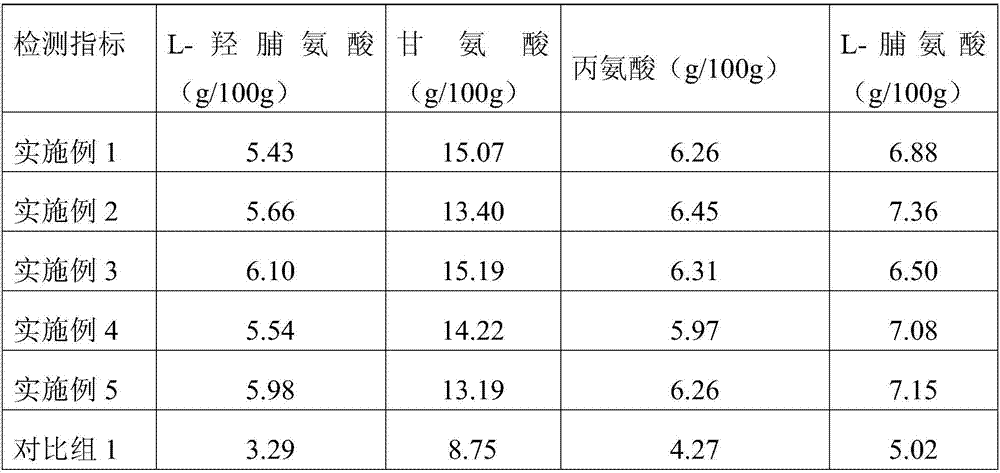

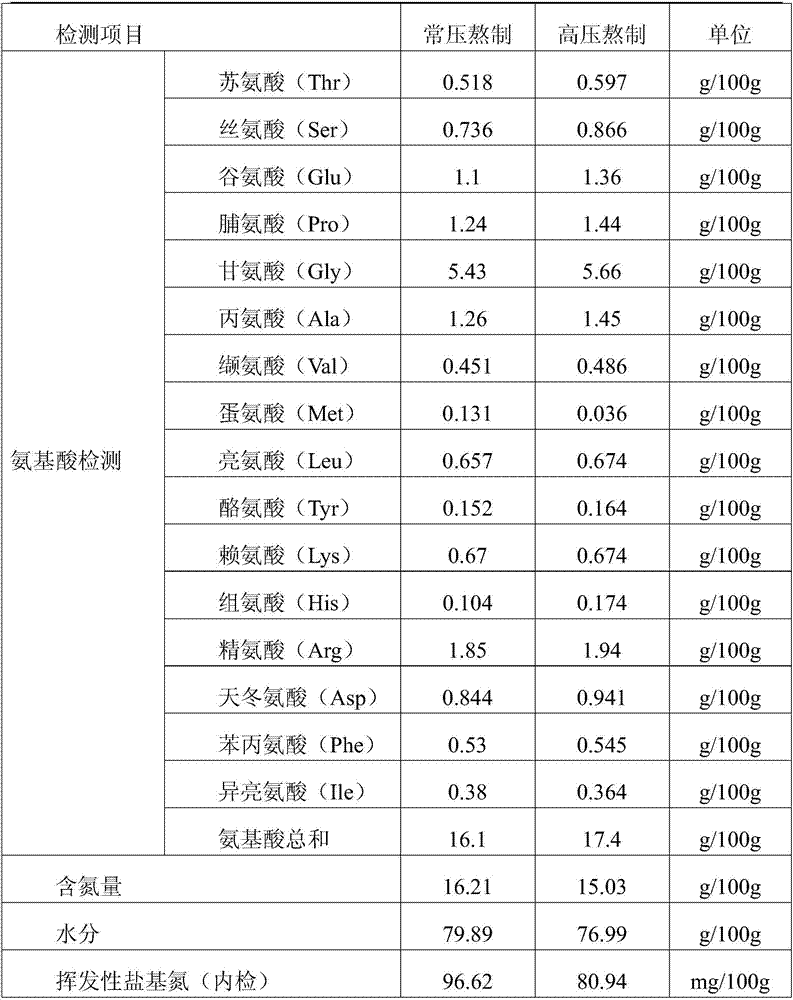

Examples

Embodiment 1

[0028] A preparation method for tortoiseshell glue, comprising the following steps:

[0029] (1) Clean the sundries inside and outside the tortoise shell with water, remove the residual meat, crush it for later use, and use a crusher to crush it until the particle size is 2cm 2 , to ensure that the tortoise shell is fully boiled and the glue is convenient after boiling.

[0030] (2) Place the broken tortoise shells in a container for dry steaming, the dry steaming temperature is 150°C, the dry steaming time is 5 hours, and stir once every 30 minutes to ensure gas circulation, ensure the effective volatilization of volatile basic nitrogen, and reduce the content.

[0031] (3) Add water to the dry-steamed container in step (2), the weight ratio of tortoise carapace to water is 1:8, cook for 60 minutes, drain and wash with water.

[0032] (4) Adding water and pressurizing the boiled tortoise shell to boil completely, the weight ratio of the tortoise shell to water is 1:4, the p...

Embodiment 2

[0036] (1) Clean the sundries inside and outside the tortoise shell with water, remove the residual meat, crush it for later use, and use a crusher to crush it until the particle size is 7cm 2 , to ensure that the tortoise shell is fully boiled and the glue is convenient after boiling.

[0037] (2) Place the broken tortoise shells in a container for dry steaming. The dry steaming temperature is 180°C, and the dry steaming time is 2 hours. Stir once every 20 minutes to ensure gas circulation, ensure effective volatilization of volatile basic nitrogen, and reduce content.

[0038] (3) Add water into the dry-steamed container in step (2), the weight ratio of tortoise carapace to water is 1:6, cook for 30 minutes, drain and wash with water.

[0039] (4) Adding water and pressurizing the boiled tortoise shell to boil completely, the weight ratio of the tortoise shell to water is 1:2, and the pressure is 0.22Mpa and boiled for 16 hours to obtain a mixed sample of the tortoise shell...

Embodiment 3

[0043] (1) Clean the sundries inside and outside the tortoise shell with water, remove the residual meat, crush it for later use, and use a crusher to crush it until the particle size is 5cm 2 , to ensure that the tortoise shell is fully boiled and the glue is convenient after boiling.

[0044] (2) Place the broken tortoise shells in a container for dry steaming, the dry steaming temperature is 200°C, the dry steaming time is 3 hours, and stir once every 30 minutes to ensure the gas circulation, ensure the effective volatilization of volatile basic nitrogen, and reduce the content.

[0045] (3) Add water into the dry-steamed container in step (2), the weight ratio of tortoise carapace to water is 1:8, cook for 50 minutes, drain and wash with water.

[0046] (4) Adding water and pressurizing the boiled tortoise shell to boil completely, the weight ratio of the tortoise shell to water is 1:4, the pressure is 0.19Mpa and boiled for 12h to obtain a mixed sample of the tortoise sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com