Efficient garbage treatment device

A waste treatment equipment and high-efficiency technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as waste of resources, impact on environmental sanitation, waste of land, etc., to meet the needs of use, easy to use, and provide efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

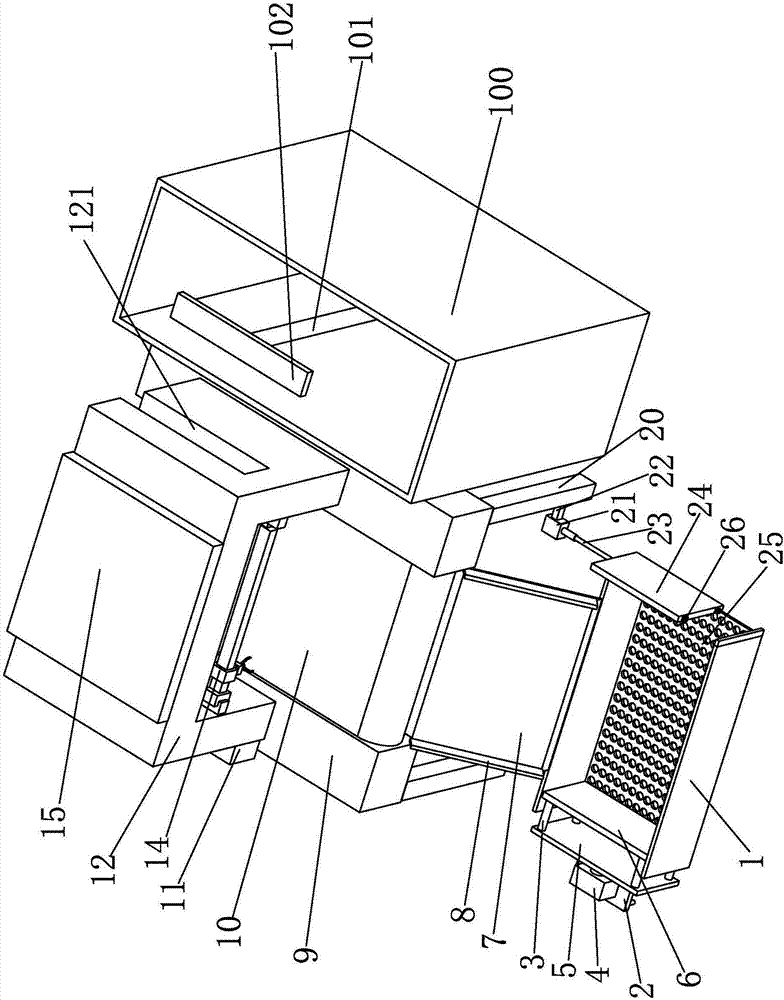

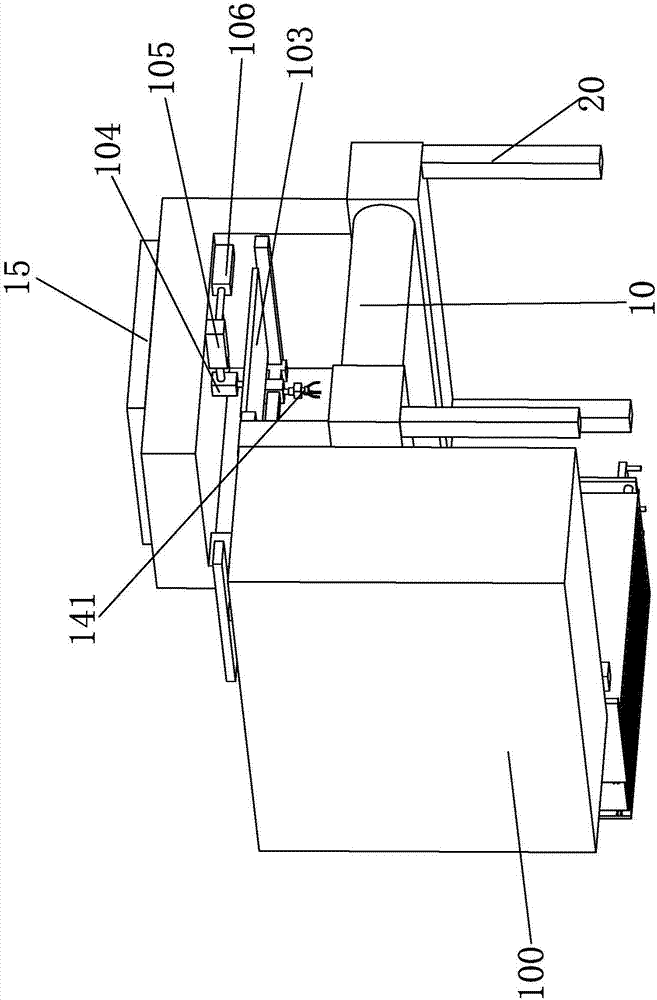

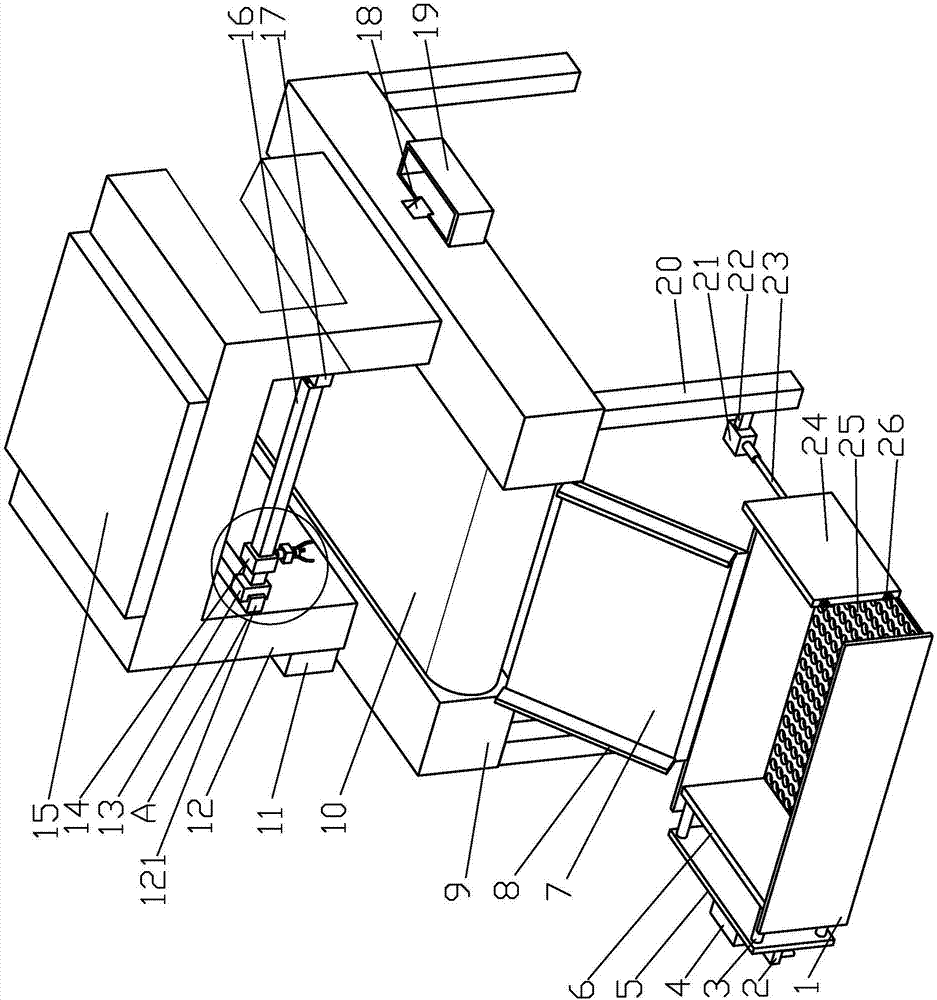

[0026] Such as Figures 1 to 6 The shown a kind of high-efficiency garbage disposal equipment includes a workbench 9, a tripod 20 is provided at the four corners of the lower surface of the workbench 9, a conveyor belt 10 is arranged in the middle of the workbench 9, and a conveyor belt 10 is arranged at the middle of the workbench 9. The middle part of the upper surface is provided with a U-shaped plate 12, and the left side of the U-shaped plate 12 is provided with a single-chip microcomputer 11, and the upper surface of the U-shaped plate 12 is provided with a metal detector 15. 12 is provided with a grabbing mechanism 141 capable of grabbing metal, and an inclined plate 7 is fixedly connected between the workbenches 9 below the outlet end of the conveyor belt 10, and a storage box 1 is provided at the lower end of the inclined plate 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com